Batch Ovens

Heavy-Duty Custom Batch Ovens Made in America

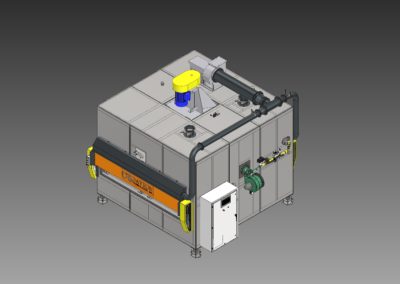

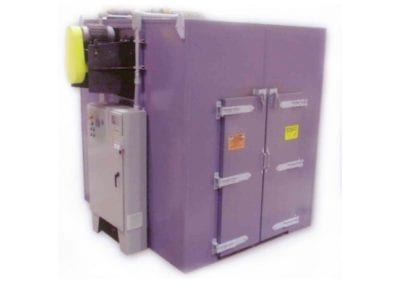

With over 100 years of combined experience, Davron designs and manufacturer’s large custom batch and walk-in ovens in virtually any combination of width, height, and depth. These are not tongue and groove panel ovens like many on the market today – our batch ovens feature structural steel frames internal to the insulated walls of the oven. This construction method provides an oven of undisputed quality that is energy efficient and extremely robust to serve in industrial applications for many years.

Featureset

Features can be customized depending on your needs. Typically the airflow within the heated chamber is designed with a recirculating horizontal cross-flow. They can also be equipped with a combination airflow pattern, top-down or bottom-up airflow pattern. Our batch ovens offer various heating methods, including gas, electric, infrared, and radiant heating systems.

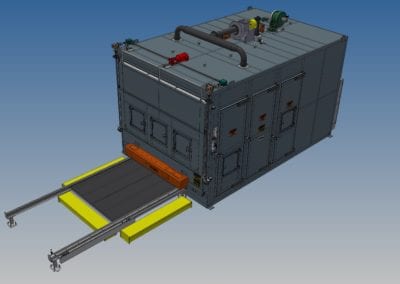

Our batch ovens can include a dedicated cooling cycle, if required. Numerous flooring options are available such as recessed tracks to accommodate product carts, a steel plate floor, or an insulated floor without tracks. Doors can be designed to accommodate any requirement and range from simple horizontal swing doors to pneumatic or hydraulic vertical doors with manual or automatic operation.

In many cases, Davron designs custom product carts and loading systems for its batch ovens. These can range from simple, manual-loaded systems to more complex, automated loading systems.

Materials

Each batch oven manufactured by Davron includes the following:

- Welded structural steel framework for overall support

- Heavy gauge aluminized or stainless steel interior sheeting and air distribution systems.

- Seal welded interior

- Shipped as single piece construction or bolt-together modules for ease of installation

- Hinged doors are provided for access to the heated chamber

- Simple digital controls for basic operation or PLC controls for complex requirements

- Electrical enclosure is assembled in accordance with UL508A guidelines and has a UL508A label

- All ovens meet NFPA, OSHA, and NEC requirements

- CE certification is available if required

Batch Ovens We Have Built

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355