DTI-1259 Curing Ovens

Customer directive

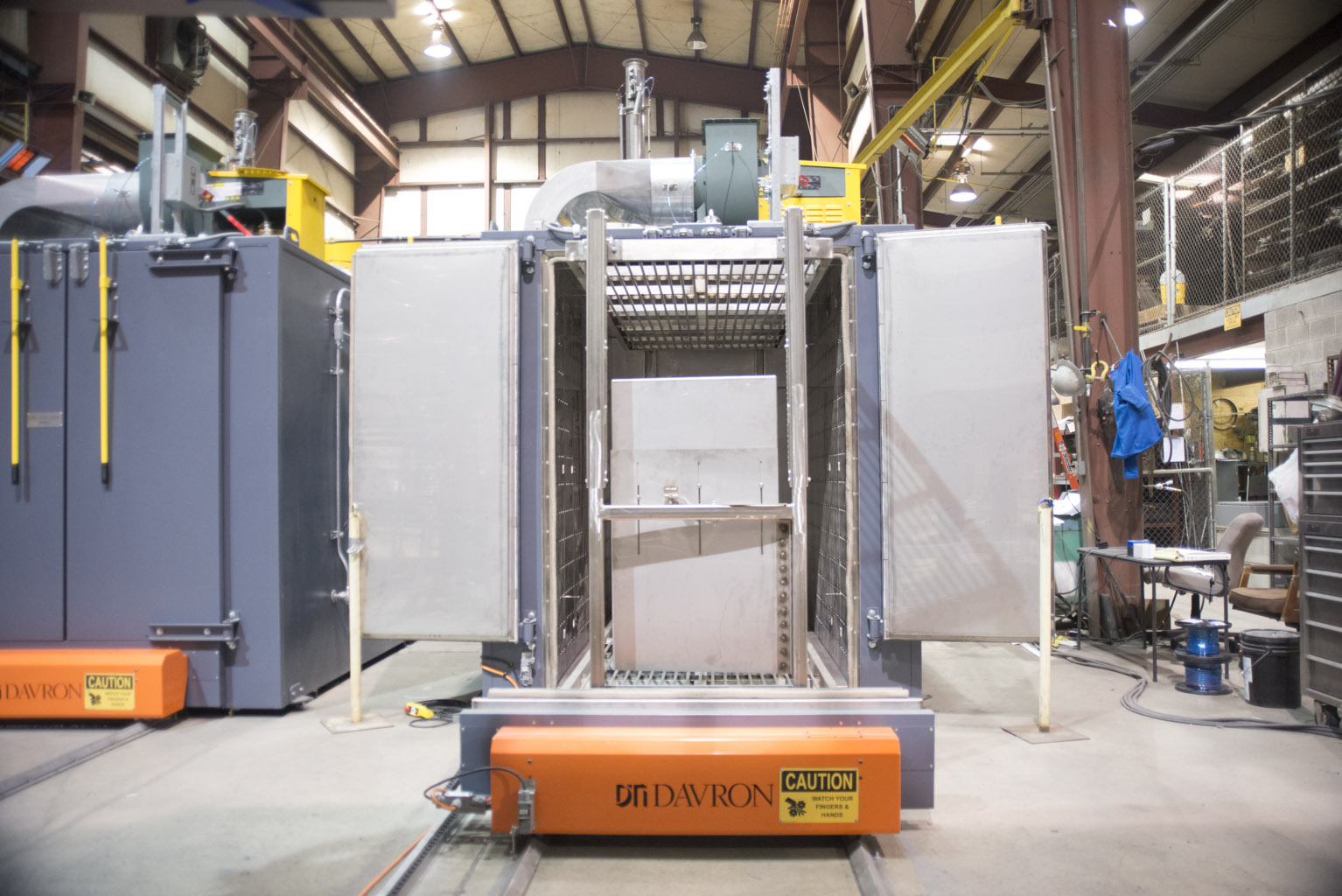

The DTI-1259 Cure Ovens were designed to place the honeycomb composite product on a powered cart assembly that would move the product in and out of the heated chamber for process. The product has openings that required the airflow to be horizontal in order to heat the product efficiently for this process. This system was specifically designed to provide a horizontal right to left airflow through the product. The cart design provided an easy means to move the product in and out of the heated chamber. With tracks recessed below finished floor, the work space in front of the oven remained clear and safe for traffic. The airflow design provided efficiency in regards to process time and uniformity.

Description

The DTI-1259 Cure Ovens provide a horizontal right to left airflow arrangement to heat this particular product. The design velocity accounts for the pressure drop through the product to provide an efficient process. The powered cart provides a stable surface to support the product and is designed to help direct airflow through the product. The design of the cart allows the customer to load and unload product easily from floor level, and the cart travels approximately 15 feet in just 30 seconds to move into and out of the heated chamber quickly. The control system includes PLC control of the cart, ramp and soak temperature profile controls, accelerated cooling cycle, as well as starting sequence for all components. This system as utilizes a Lower Explosive Limit (LEL) monitor due the possibility of trace volatile off-gassing from the product. These ovens are ducted to a thermal oxidizer to ensure safe handling of all exhaust fumes from the product. A paperless chart recorder is included to record all thermal processes for product validation and record. All functions are controlled from the operator HMI (touch screen) and multiple recipes can be stored for future use for various product requirements. The entire system is fully assembled and factory tested for operational verification prior to shipment.

Specifications

| Product Being Processed | Honeycomb composite material used in Aerospace products |

| Overall Length, Width and Height | 16′-7″ L x 8′-10″ W x 10′-11″ H (5050mm x 2690mm x 3330mm) |

| Heated Chamber Length, Width, Height | 11′-2″ L x 5′-0″ W x 7′-5″ H (3400mm x 1520mm x 2260mm) |

| Type of Heating System | Electric |

| Designed Operating Temperature | 350°F (177°C) |

| Maximum Operating Temperature | 550°F (288°C) |

| Product Support | Powered product cart |

| Controls | PLC control with operator HMI, UL listed control enclosure, LEL monitor, chart recorder |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Designs can be completed to provide airflow from any direction within the heated chamber as required by the product. This particular process provides horizontal airflow but it can be vertical up or down.

- Industries Served: Aerospace, Catalyst Manufacturing/Regeneration, or any industry that requires Plastics, foam, carpet, textile, paper, foil, sheet batch processing.

- Materials Processed: Particularly any Honeycomb Core or Cellular type product with a directional flow requirement, similar Composite materials. The oven /cart system can also be used for many other types of products and can be designed in any size required.

- Other Processes: Preheating, Curing, Drying, Solvent Drying, Bonding

- Heating Systems: Modulating Gas Fired Direct or Indirect, Electric, or Thermal Oil.