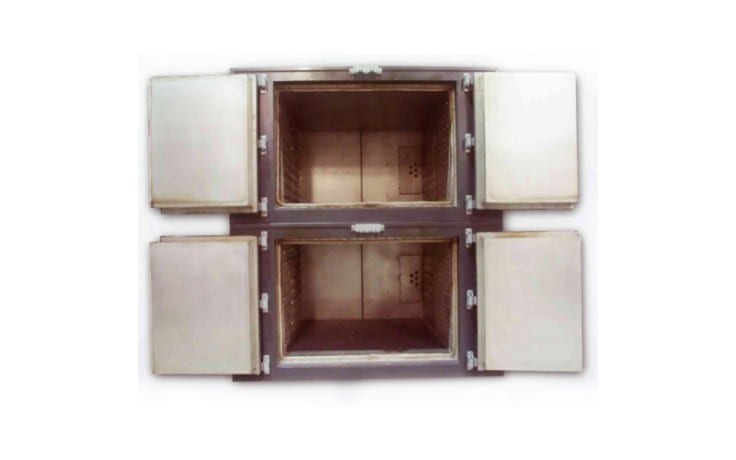

DTI-1004 Double Stack Preheat Batch Oven

Description

The DTI-1004 batch ovens preheat steel molds used in the plastic industry. These batch ovens are designed so that the roofs are clear of all components, allowing the ovens to be stacked on top of one another to conserve floor space. The batch ovens do not have to be stacked, and can work independently of each other. Each batch oven is independently controlled, and utilizes its own heater, circulation fan, and exhaust fan. Each batch oven is designed to support 6,000 pounds of steel molds. The molds are loaded in the oven and heated to 750°F (399°C) within four (4) hours. The product then soaks at 750°F for the remainder of the process.

Specifications

| Exterior Dimensions | 9′-3″ L x 9′-4″ W x 5′-4″ H (2819mm x 2845mm x 1626mm) |

| Interior Dimensions | 6′-0″ L x 6′-0″ W x 4′-0″ H (1829mm x 1829mm x 1219mm) |

| Heat Source | Single electric heater controlled by SCR |

| Maximum operating temperature | 800°F (427°C) |

| Design Operating temperature | 700°F – 750°F (371°C – 399°C) |

| Insulation Thickness | 8″ (203mm) |

| Operating voltage | 480-volt / 3-phase / 60-hertz |

| Airflow | Horizontal cross flow |

| Circulation Fans | One (1) circulation fan |

| Control | No controls included with this oven, the customer tied the ovens into their existing control system |

Alternative capabilities

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous