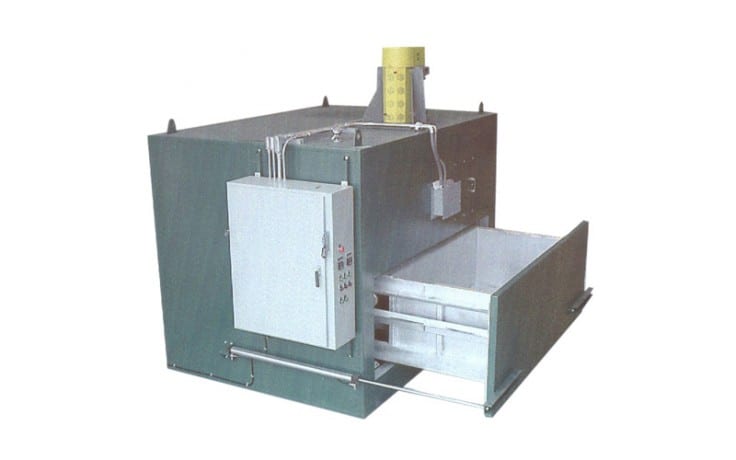

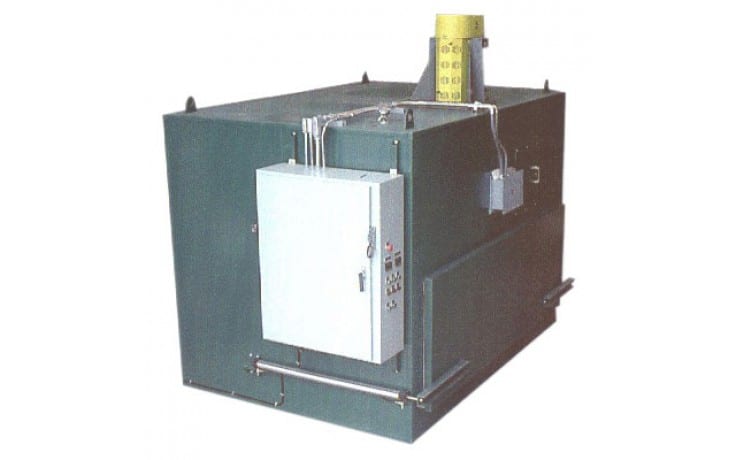

DTI-227 Pre-Heat Drawer Oven

Description

The DTI-227 industrial oven preheats cast iron molds used in the plastic industry. This custom oven contains a drawer that opens and closes automatically. Molds are loaded into the drawer by a crane located in the customer’s facility. Once the drawer closes, the preheat cycle begins. The custom oven drawer will support a maximum load of 4,000 pounds. The heat system is designed for a maximum product load of 4,000 pounds of steel.

Specifications

| Overall Dimensions | 7′-3″ L x 9′-7″ W x 6′-0″ H (2210mm x 2921mm x 1829mm) |

| Interior Dimensions | 3′-0″ L x 6′-0″ W x 2′-0″ H (914mm x 1829mm x 610mm) |

| Insulation Thickness | 4″ (102mm) |

| Heat Source | Single electric heater controlled by SCR |

| Maximum Operating Temperature | 400°F (204°C) |

| Operating Temperature Range | 250°F – 400°F (121°C – 204°C) |

| Fans | One (1) circulation fan |

| Airflow | Vertical top down |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Miscellaneous | Digital indicating temperature controller |

| Digital indicating over temperature controller |

Alternative capabilities

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous