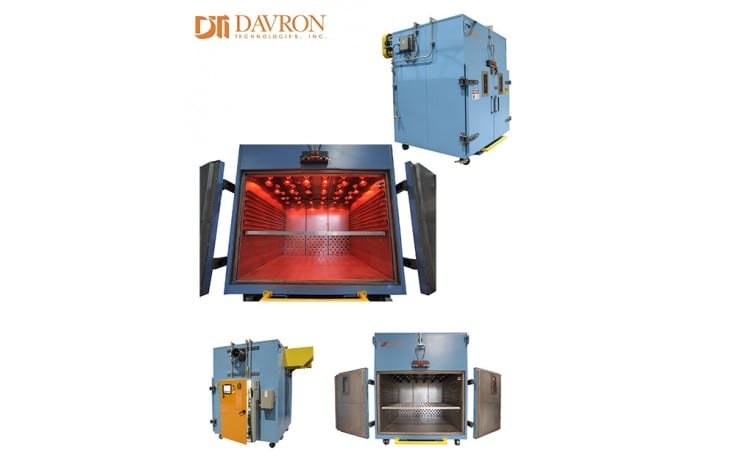

DTI-1202 Preheat Batch Oven

DESCRIPTION

The DTI-1202 custom preheat batch oven is used to heat a polypropylene product used in the automotive industry. The oven heats the product to simulate the extreme conditions that occur during the life cycle of the vehicle. The heat source of the oven is a combination of IR heat lamps and convection heat. The operating temperature range of the IR section of the oven is 212 °F to 266 °F. The operating temperature of the convection section of the oven is 392 °F. The airflow within the convection section is a horizontal cross flow pattern. The oven includes two (2) viewing windows in the doors and one (1) adjustable shelf to allow product to be placed at variable locations within the heated chamber. The entire oven is on casters to allow for portable operation.

SPECIFICATIONS

| Overall dimensions | 6′-4″ L x 7′-2″ W x 8′-4″ H (1930mm x 2184mm x 2540mm) |

| Interior dimensions | 5′-8″ L x 6′-6″ W x 6′-0″ H (1727mm x 1981mm x 1829mm) |

| Insulation thickness | 4″ (102mm) |

| Heat Source | IR Heat Lamps and single electric heater controlled by SCR |

| Maximum operating temperature | 392°F (200°C) |

| Operating temperature range | 158°F – 266°F (70°C – 130°C) |

| Operating voltage | 480-volt / 3-phase / 60-hertz |

| Control | PLC with Operator Touch Screen (HMI) for all functions |

| Misc | Control Panel assembled in accordance with UL508A guidlines |

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous