Industrial Foam Ovens

Custom-engineered industrial foam ovens and foam conversion equipment for your unique manufacturing requirements

With applications in almost every conceivable realm of commercial and consumer life, foam products are rightly among the most important and most dynamic manufactured in industry today.

And, owing to its breadth of use, the number of formulas and manufacturing methods available are essentially infinite. The equipment foam manufacturers rely on for their production is arguably their most precious investment.

Do you trust something off the shelf?

Custom batch and continuous foam manufacturing ovens from Davron are ideal for a wide range of thermal processes, including:

- Crosslinking

- Expanding/foaming

- Curing

- Cooling

- Part A and part B preheating

Every oven or other piece of equipment we make is 100% custom-tailored to your proprietary formula and process. Our team has built ovens for both web-type foam and buns, blocks or cut blanks of a wide range of materials, such as:

- Polyethylenes

- Polyurethanes

- Polyolefins

- Copolymers

- Fluoropolymers

- Elastomers

Superior engineering for superior quality

Producing a consistently high-quality product is crucial for foam manufacturers.

And because foam manufacturing relies on complex chemical reactions, production equipment must be carefully calibrated for precise delivery of heat and air.

When required, we can engineer machinery with automated adjustable airflow and multi-zone temperature control to sustain ideal conditions for sensitive or complex processes.

Launching a new product or considering an equipment or process overhaul and need foam oven engineering guidance? Learn more about pre-engineering services from Davron.

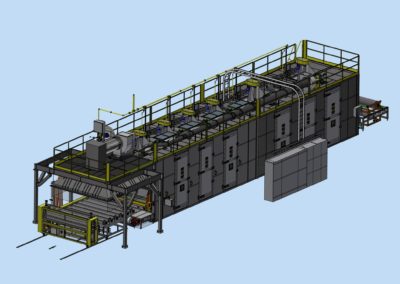

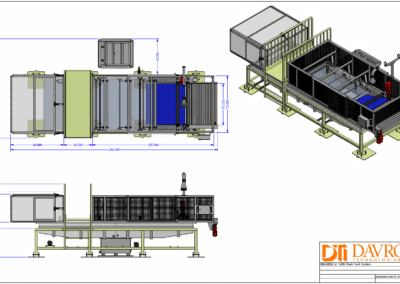

Conversion equipment rounds out your foam manufacturing line

In addition to ovens that crosslink, expand or cure foam products, our engineers have developed extensive expertise in designing and building pre- and post-process conversion equipment to further streamline operations.

Examples of this equipment include:

- Cooling rolls and cooling baths

- Material compression rolls

- Slitting and crosscutting

- Winding and package prep

Talk with a Davron engineer about your foam manufacturing requirements.

Custom industrial foam ovens we’ve built

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355