AUTOMOTIVE OVENS

Custom automotive ovens built for higher throughput and consistent quality

Thermal processing is integral to countless production stages up and down the automotive supply chain. And at every stage, manufacturers can only thrive if their operations are consistent, reliable and efficient.

Davron Technologies is an established provider of custom thermal process systems that meet Tier 1 and Tier 2 suppliers’ highly technical process requirements. We’ve designed and built equipment that spans all corners of the industry, with applications that include:

- Interior components such as carpet sets, headliners & dash liners and instrument panels

- Engine parts including pistons, cams, valves, stators and clutches

- Exterior components like body panels, underbody acoustics and wheel well liners

- Suspension components including coil springs, shocks, bushings and brake pads

We understand automotive

Automotive suppliers face a steep uphill climb to be profitable, confronting a cascade of challenges:

- The declining price structure of production contracts

- Exceedingly specific, highly technical product specs

- Stringent documentation requirements for safety-critical parts

- Pressure to achieve ROI on manufacturing equipment

But it all boils down to cycle time and cost.

Automotive ovens must achieve desired throughput requirements, and they must pay for themselves. Manufacturers’ profitability depends on it.

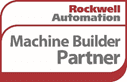

We’ve delivered a wide variety of oven concepts and heating methods to automotive manufacturers across North America:

- Forced air convection, contact and IR/radiant heating

- Batch or conveyor ovens

- Inert atmosphere ovens

- Vertical ovens

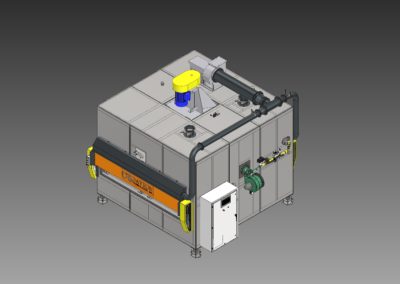

- Pre- and post-heating loading and unloading equipment

- Heating via natural gas, electricity and thermal oil

Next-generation automotive thermal processing

Robust controls and comprehensive data collection are integral to automotive manufacturing in the 21st century.

As a certified Rockwell Machine and Equipment Builder Partner, Davron builds ovens that sync seamlessly with existing automated production process.

In addition, our engineers are well-versed in designing pre- and post-process loading and unloading equipment such as pick and place systems. These are controlled by PLC to provide proper timing to match or improve your facility’s part-to-part cycle times.

It’s all possible thanks to the experts in our UL-certified in-house electrical shop.

The manufacturer’s guide to successful automotive textile thermal processing

Download >Custom automotive ovens we’ve built

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355