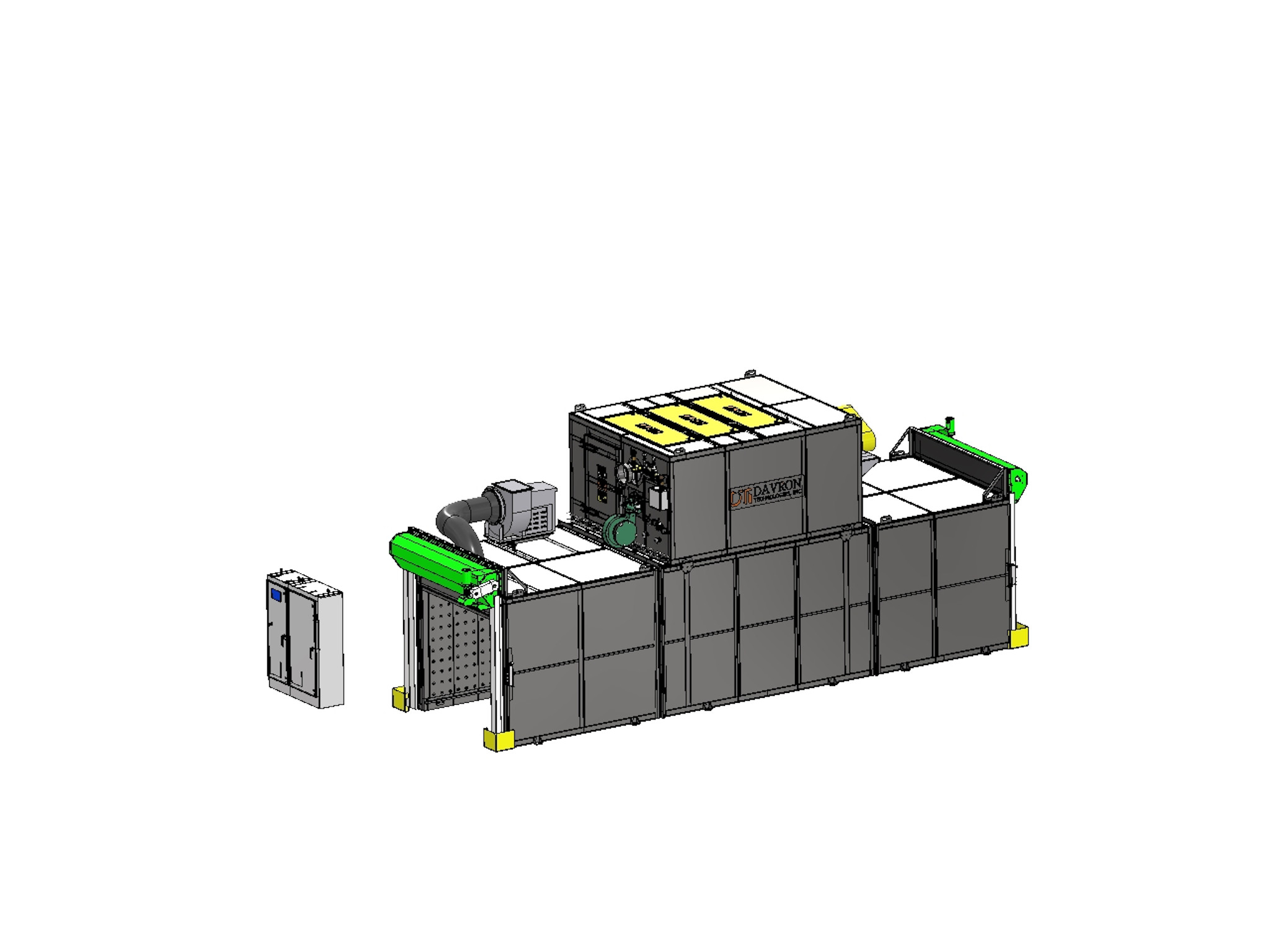

DTI-1489 Curing Batch Oven

Customer directive

This customer is involved in the memorialization industry, providing services to cemeteries, funeral homes, monument dealers, and sign shops across the globe. For this application, the customer requested a batch oven to process their bronze and granite memorials to be processed on large carts that could be rolled into the chamber. The carts are rolled in manually so the chamber height needed to accommodate the operators height and open on both ends so carts can be rolled into one end and out the other.

Description

The DTI-1489 batch oven features an open bottom design with forced air heating supplied from both sides returning in the top to provide adequate airflow through the customers cart design. Vertical doors on each end allow carts to be pushed in from one end and out the other. The PLC programming includes an automatic switch over to cooling where one of the vertical doors opens and the exhaust fan ramps up to pull in fresh air and cool the chamber to the desired set point. As with all of Davron Technologies equipment, this oven was shipped in complete modules with lifting lugs on each section to simplify the installation process.

Specifications

| Product Being Processed | Sand Molds, Bronze and Granite Memorials |

| Overall Equipment Dimensions | 35′-6″ L x 10′-0″ W x 14′-2″ H (10820mm x 3048mm x 4318mm) |

| Heated Chamber Dimensions | 30′-8″ L x 6′-5″ W x 6′-6″ H (9347mm x 1956mm x 1981mm) |

| Type of Heating System | Natural Gas Burner |

| Design Operating Temperature | 280°F – 400°F (138°C – 204°C) |

| Maximum Operating Temperature | 400°F (204°C) |

| Product Support | Customer provided carts |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Horizontal both sides returning to top, horizontal across the chamber, or top down returning to sides

- Industries Served: Metal casting, coatings,

- Materials Processed: Sand molds

- Other Processes: Preheating, Curing, Drying, Solvent Drying, Bonding

- Heating Systems: Modulating Gas Fired Direct or Indirect, Electric, or Thermal Oil.