BATTERY OVENS

Custom ovens for high-volume lithium-ion and lead-acid battery production

For decades, the pursuit for better batteries has spurred the development of new lead-acid and lithium-ion battery manufacturing equipment.

Today, as demand for energy storage in automotive and grid-scale applications surges, the industry needs battery production machinery that delivers at scale.

Custom ovens from Davron will play an instrumental role in this groundbreaking transition toward a clean-energy future.

Thermal processing expertise in key industries

As a custom thermal processing equipment manufacturer, Davron understands ovens. Our engineers have applied that understanding to cutting-edge solutions in industries that will soon rely on lithium-ion batteries as primary sources of energy:

Our significant automotive thermal processing resume has helped us develop an intimate understanding of how to engineer equipment that maximizes throughput for high-volume, low-margin manufacturing.

And with our roster of successful aerospace and pharmaceutical customers, we understand the role equipment providers play in ensuring the integrity of safety-critical component manufacturing.

Read about our full range of industry experience here.

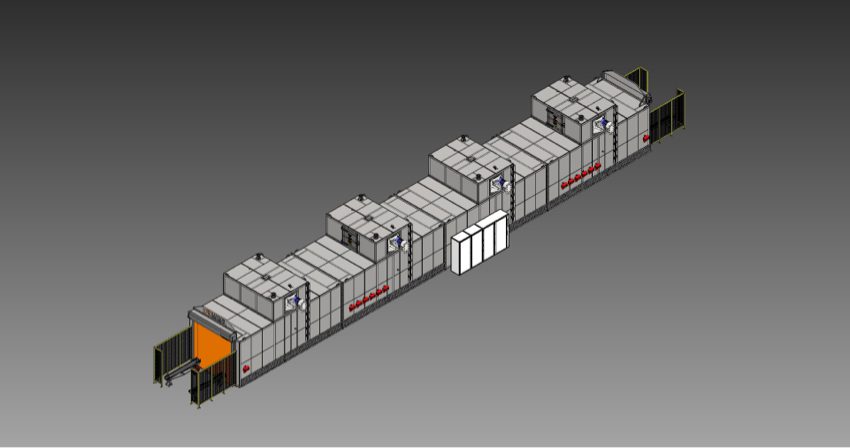

Specializing in custom ovens for lithium-ion and lead-acid battery manufacturing

Two things set Davron ovens apart: temperature/airflow control and solid engineering and construction.

Heating/airflow control – The sensitive steps involved in battery component thermal processing contain no room for error. We engineer our ovens for maximum control of temperature and airflow characteristics — and with proper maintenance, that control is consistent and reliable for the lifetime of the equipment through smart integration of advanced sensors and automation.

Quality engineering and construction – This equipment is overbuilt, and we’re proud of it. Heavy-duty construction includes specifying thicker sheet metal, steel framing, welded construction and higher-quality insulation. When properly maintained, these ovens last — and they hold their heat the entire time.

In addition, Davron manufactures pre- and post-process handling and conversion equipment designed for more seamless production that meets your unique requirements and utilizes factory space more efficiently.

That means you’ll get more for your investment without the added cost or risk of aftermarket integration of equipment assembled piecemeal.

Start a battery manufacturing thermal processing consultation

Davron engineers are expert listeners specializing in transforming vague specs or process requirements into thoughtfully engineered lithium-ion or lead-acid battery manufacturing equipment.

Because the energy storage industry remains in relative infancy, we suggest considering pre-engineering your thermal processing equipment for battery applications.

Or, we can simply talk options. Reach us here.

Learn the key criteria, best uses, heating sources & methods and customizations that combine to inform the conveyor oven specification that’s ideal for your industrial process.

Download >Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355