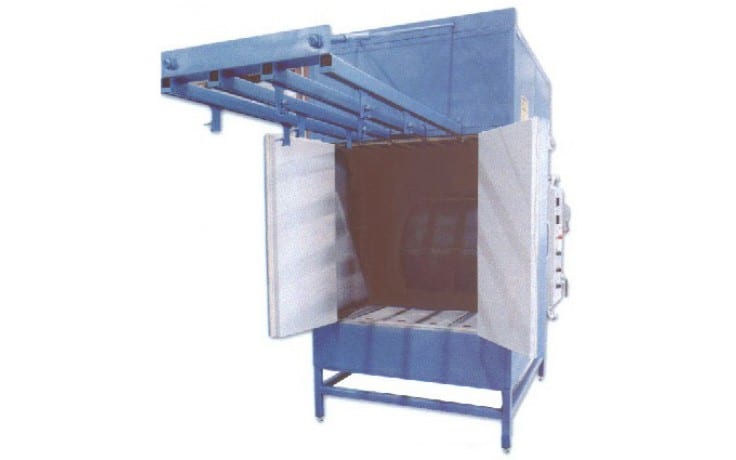

DTI-9282 Trolley Preheat Oven

SPECIFICATIONS

| Overall Dimensions | 5′-0″ L x 6′-0″ W x 6′-0″ H (1524mm x 1829mm x 1829mm) |

| Interior Dimensions | 4′-0″ L x 4′-0″ W x 4′-0″ H (1219mm x 1219mm x 1219mm) |

| Insulation Thickness | 4″ (102mm) |

| Heat Source | Single electric heater controlled by SCR |

| Maximum Operating Temperature | 400°F (204°C) |

| Fans | One (1) circulation fan |

| Airflow | Vertical from bottom to top |

| Operating Voltage | 240-volts / 3-phase / 60-hertz |

| Miscellaneous | Digital indicating temperature controller |

| Digital indicating over temperature controller | |

| The trolley tracks extend 6′-0″ outside of the heated chamber |

DESCRIPTION

The DTI-9282 industrial oven preheats sheets of acrylic used in the manufacturing of motorcycle windshields. Acrylic sheets are loaded into the oven and preheated prior to being formed to the final shape. This custom oven utilizes four (4) trolley or product tracks for loading and unloading product. Each trolley has two product clamps for holding sheets of acrylic.

Oven capacity is eight (8) sheets of acrylic per batch. Sheets are placed into the clamps located on the trolleys and loaded into the oven chamber. The custom oven is then heated to 400°F (204°C), and the acrylic sheets are heated for a predetermined amount of time. Upon completion of the cycle, the oven doors are opened and the sheets are pulled outside of the heated chamber on the trolleys for unloading.

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355