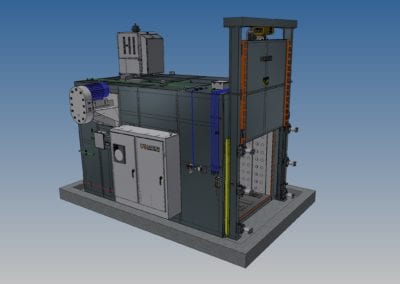

DTI-1404 Inert Atmosphere Batch Oven

SPECIFICATIONS

|

Product Being Processed |

Plastic |

|

Overall Length, Width, Height |

19′-6″ L x 12′-0″ W x 14′-7″ H (5944mm x 3658mm x 4445mm) |

|

Heated Chamber Length, Width, Height |

14′-6″ L x 6′-0″ W x 6′-0″ H (4420mm x 1829mm x 1829mm) |

|

Type of Heating System |

Electric |

|

Design Operating Temperature |

450°F (232°C) |

|

Maximum Operating Temperature |

500°F (260°C) |

|

Product Support |

Cart system, 1/4″ plate floor with cart tracks |

|

Controls |

PLC controls with operator HMI, UL listed control enclosure |

CUSTOMER DIRECTIVE

DTI-1404 is designed to perform a curing cycle for military plastics. Due to the nature of the product this oven must operate at extremely low levels of atmosphere while at temperature. Exposure to oxygen above a set temperature can potential ruin the product, so extreme care is taken to ensure all seams and joints are minimized and designed in such a way to prohibit introduction of atmosphere to a heated cycle. The oven door was designed as a vertical opening door to minimize foot print and aid access to the oven chamber, while maintaining a complete seal around the opening.

DESCRIPTION

To achieve extremely low levels of oxygen the oven has been completely Heliarc (TIG) seal welded. All oven penetration has been minimized and sealed to ensure no air is pulled inside. A slight positive pressure in the chamber is controlled with a self-regulating release valve, ensuring a complete purging of the interior during the run cycle.

A stainless steel cooling coil and thermal oil unit perform an assisted cooling ramp. This decreases thermal shock and deposit build-up experienced by using cooling water as a cooling medium.

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. designs and manufactures custom industrial ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Horizontal, vertical, special application

- Industries Served: Automotive, pharmaceuticals

- Materials Processed: Glass, ceramics, various plastics

- Other Processes: Baking, pre-heating, curing, drying, sintering, heat forming, annealing

- Heating Systems: Electric, hot oil, gas (for non-inert batch type)

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355