AEROSPACE OVENS

Custom-designed for exceptional precision and process control

From safety-critical composites to tray tables and arm rests, aerospace manufacturers produce a wide range of products requiring extremely precise thermal processes.

In an industry where passenger and crew safety are paramount, OEMs and their suppliers must be certain the equipment they rely on can perform.

Davron’s expert engineers tailor aerospace ovens and other precision thermal process equipment to the industry’s most stringent requirements. Our ovens feature:

- Balanced airflow and precise temperature profiles for even, consistent processing

- Custom engineering to meet your exact process parameters

- Heavy-duty construction with quality parts for a long, low-maintenance service life

- State-of-the-art digital controls and data collection so you can maintain traceability

The result?

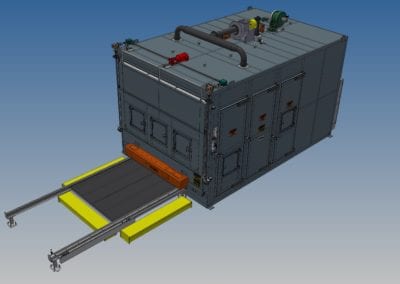

Specialized composite thermal processing equipment

Davron has developed a special expertise in designing custom composite and core thermal processing equipment used in the production of honeycomb materials, instrumental in the manufacture of aerospace control surfaces.

This equipment includes:

- Dip tank systems

- Solvent curing ovens

- Final cure/heat treat ovens

- Pre- and post-process handling and conversion equipment

Our equipment can process a wide range of materials, including prepreg material, carbon fiber, honeycomb blocks and many more composites.

Have a project in the works? Want to know more about our approach to designing custom aerospace thermal processing equipment?

Learn the key criteria, best uses, heating sources & methods and customizations that combine to inform the conveyor oven specification that’s ideal for your industrial process.

Download >Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355