It’s different here.

Davron engineers and builds uncompromising thermal equipment for manufacturers

100% success rate,

through hundreds of unique systems

Standard equipment holds proprietary processes back. Our expertise delivers innovative, built-to-spec equipment to elevate your process.

Designed to fit your parameters

Design starts with listening to you. So your equipment is engineered to achieve your goal throughput and deliver the ROI you need. And we build in adjustability, so you can fine-tune your process over time as needed.

Innovative equipment you can trust

Our unique brand of engineering, manufacturing and testing can work within extreme or unique parameters. Flexible in-house manufacturing allows us to utilize outside-the-box concepts to deliver equipment as innovative as your process needs.

Consistent parts, processed with precision

Structural steel-framed ovens with best-available insulation and expertly designed airflow systems deliver perfect parts consistently for years.

Get expert attention on

projects of any scale

Need a built-to-fit oven?

If thermal processing is producing imperfect parts, bottlenecking your line or straining your labor force, you’re due for an upgrade. A standard oven may not check every box for you, but we develop custom solutions to upgrade your process efficiency and part consistency. And we’ll build it in house, with durable materials

Need a built-to-fit oven?

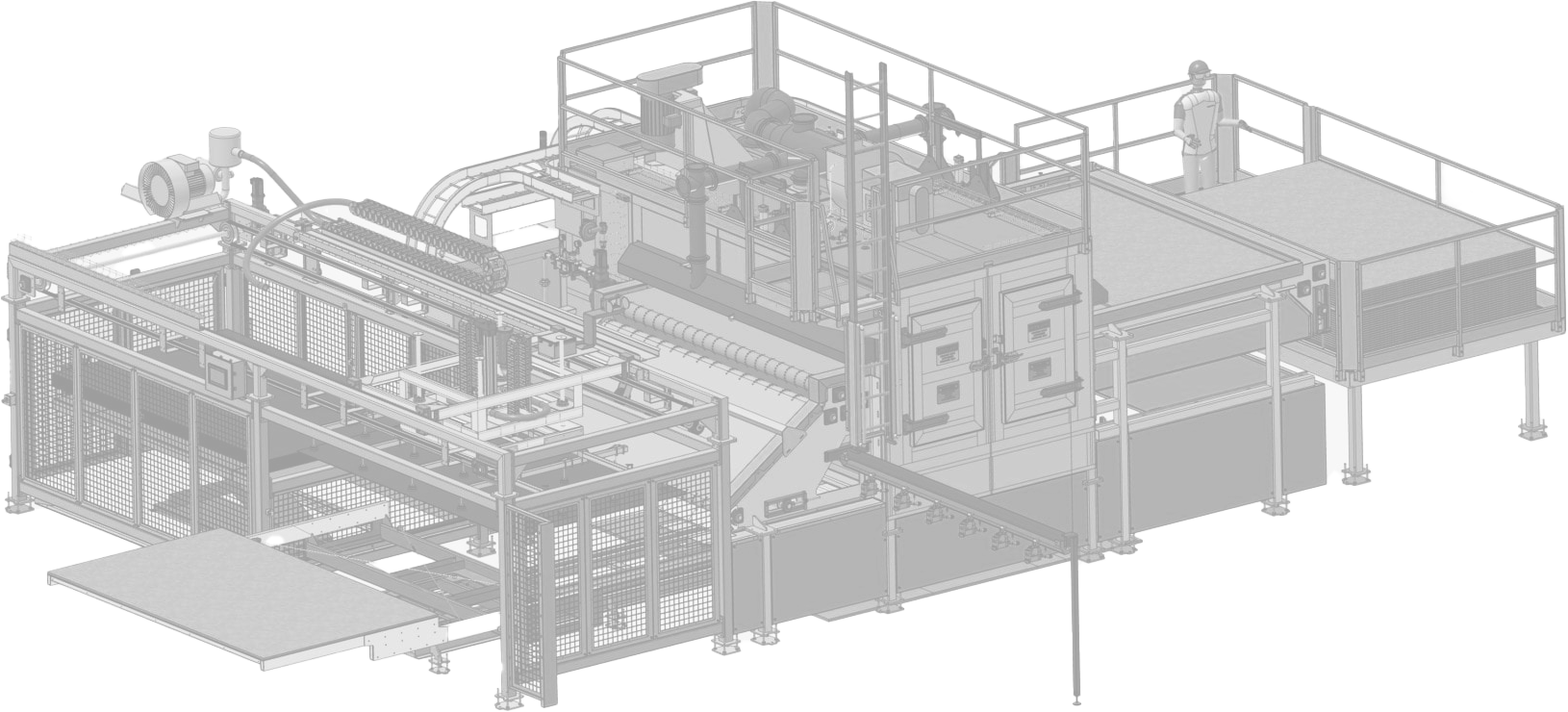

Need more than just an oven?

Assembling a production line of specialty equipment from various suppliers presents a significant integration challenge and a mountain of specification work. Davron can design, build and integrate entire production lines, including upstream and downstream equipment, to process your parts both before and after heating. All on a single P.O.

Need more than just an oven?See what our customers say

“I needed a team I could connect with, have them really get involved in our business and take my ideas and designs that I know would work in our process and massage them into their product line and what they’re building.”

“Once they turned on and we got them running, they were plug and play. They were exactly how the runoffs left.”

“They came across as honest guys, professionals, and we rolled the dice. They keep taking our business and we keep coming back to them.”

“Anyone can build a tank to squash a bug … We don’t buy standard, off-the-shelf equipment. When we buy what we buy from Davron, we get a solution that helps us produce what we want to produce.”

“They could do anything we wanted them to do. Their versatility was what really won our business in my opinion.”

“Their technical expertise has been a huge plus in helping us design. And really taking our ideas and understanding where we’re trying to go with things, and being able to come up with a really good design that really emits what we were envisioning the whole time.”