DTI-962 Powder Coat Cure System

SPECIFICATIONS

| Overall Dimensions | 60′-4″ L x 18′-0″ W x 12′-0″ H (18390mm x 5486mm x 3658mm) |

| Insulation Thickness | 6″ (152mm) |

| Heat Source | Gas Fired Heater Banks, Modulating Gas Fired Burner in Convection Burner Box |

| Maximum Operating Temperature | 500°F (260°C) |

| Operating Temperature Range | 300°F – 500°F (149°C – 260°C) |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Control | Modulating Burners with Closed Loop Control |

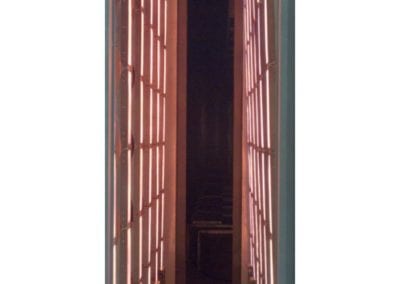

| Gas Infrared Section Dimensions | 12′-0″ L x 4′-6″ W x 12′-0″ H (3658mm x 1372mm x 3658mm) |

| Miscellaneous | Modular Construction for Shipping and Installation in Sections. |

| Conveyor Pass Height 6′-10″ (2083mm) | |

| Conveyor Extensions Serpentine through entire paint system | |

| Conveyor Type Overhead MonoRail | |

| Conveyor Speed Control Variable Frequency Drive |

DESCRIPTION

The DTI-938 specialized oven system cures powder paint on metal panel assemblies. This system utilizes both infrared and convection heating to complete the cure process. The conveyor design speed is 18′ (5486mm) per minute, providing 40 seconds of infrared heat, followed by 10 minutes of convection heating, and completed with 21 seconds of cooling.

The infrared section provides heat by using a series of gas fired infrared burners located on each side of the product. This section is used to heat the powder paint very quickly to gel the paint to the parts to prevent the convection section from blowing the powder paint off the parts. The infrared is followed by 10 minutes of forced air convection heat to finish the cure process.

FEATURES

CUSTOM OVEN CONSTRUCTION FEATURES

The air circulation within the convection chamber is vertical up, and air is circulated through a burner box located on top of the system. The final section is a cooling section designed to reduce the part temperature prior to exit. This section also serves as a vestibule to limit the amount of heat escaping to the plant. The system design provides the ability to cure 12,000 pounds of product per hour at design speed.

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355