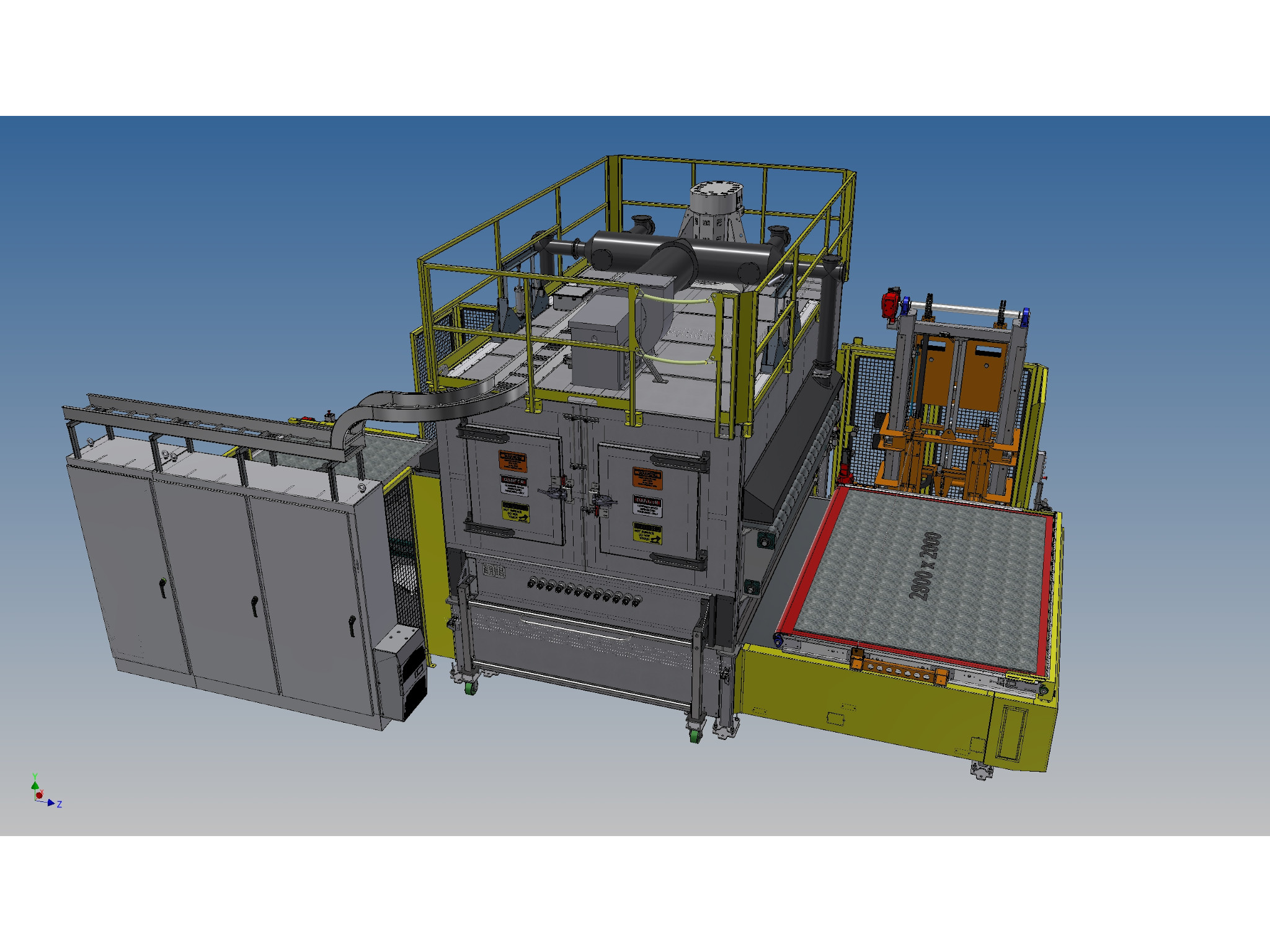

DTI-1412 IR/Convection Oven

Customer directive

The DTI-1412 pre-heating system addresses the need for two automotive carpet products to be pre-heated and stacked one on top of the other before being pressed into their final shape. To add challenge, the two materials are quite different in nature and require two different types of heating processes.

To meet this need, Davron designed and built a pre-heating system that heats the two carpet layers independently with convection heat for the light backing material and infrared (IR) heat for the carpet layer. These systems are stacked one above the other and incorporated together. A lift conveyor functions as an elevator for the top level, allowing operators to load from ground level without need for a mezzanine. The two pieces are conveyed through the heat and then stacked precisely on top of each other, while being delivered out onto a high temp Teflon conveyor for unloading.

Description

On the entry end, the lift conveyor is a fully cantilevered conveyor bed, offering two open sides for load access. This counterweighted system, raises the product up to match the level of the upper conveyor and index the material into the upper oven. The conveyor bed rests on top of the lower flat wire belt conveyor below, for loading. Once loaded it is raised and the lower conveyor is loaded. These index from a load position to a single heated position; convection above, IR below. Once heated the upper material is conveyed down a decline to meet the lower conveyor at the precise time the lower material is conveyed out, stacking the two products with high precision and accuracy. From there, the stacked and pre-heated materials are manually transferred to a press. This system produces one part every 60 seconds.

Specifications

| Product Being Processed | Automotive carpet and backing pad |

| Overall Length, Width, Height | 30’-4” L x 16’-0” W x 13’-4” H (9246mm x 4877mm x 4064mm) |

| Heated Chamber Length, Width, Height | 8’-9” L x 10’-2” W x 1’-6” H (2667mm x 3099mm x 457mm) |

| Type of Heating System | Gas (top convection oven), IR heat (lower) |

| Design Operating Temperature | 450°F (232°C) |

| Maximum Operating Temperature | 500°F (260°C) |

| Product Support | Flat-wire conveyor belting, Teflon conveyor belting |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures custom industrial ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Top down/bottom up vertical, horizontal

- Industries Served: Aerospace, Automotive, textile

- Materials Processed: wovens, non-wovens, carpet, plastics

- Other Processes: Drying, curing, bonding,

- Heating Systems: Gas, electric, hot oil, contact/conduction