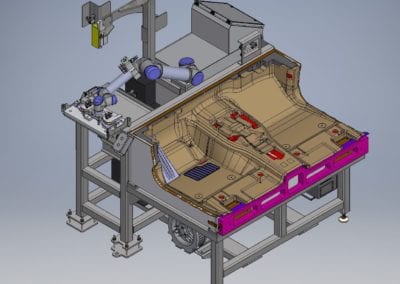

DTI-1330 Automated Assembly Machine

SPECIFICATIONS

|

Product Being Processed |

Automotive carpet, plastic part |

|

Overall Length, Width, Height |

5′-5″ L x 6′-0″ W x 6′-2″ H (1651mm x 1829mm x 1880mm) |

|

Heated Chamber Length, Width, Height |

N/A |

|

Type of Heating System |

N/A |

|

Design Operating Temperature |

N/A |

|

Maximum Operating Temperature |

N/A |

|

Product Support |

Base frame with assembly buck/fixture and collaborative robot with end of arm tooling |

|

Controls |

PLC controls with operator HMI, UL listed control enclosure |

CUSTOMER DIRECTIVE

The customer was having issues with their existing process of an operator applying glue to a plastic foot rest and setting on an automotive carpet. Glue application and foot rest location were inconsistent due to human error. DTI-1330 utilizes a 6-axis collaborative robot to apply glue to the foot rest and apply the part to the carpet accurately and consistently.

DESCRIPTION

Once the operator has placed a carpet and foot rest on the machine, the assembly machine will verify that the parts are present, orientated correctly, and even verify matching colors. The 6-axis collaborative robot will then pick the foot rest up with vacuum cups, apply a hot melt glue to the back, and place the part on the carpet. The finished product is removed and another foot rest and carpet put in its place.

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. can design and manufacture more than just ovens to meet many unique process requirements, including but not limited to, the following:

- Industries Served: Automotive, aerospace, textile

- Materials Processed: Automotive acoustics, carpet, plastics

- Other Processes: Assembly, inspection

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355