DTI-775 Compact Impingement Curing Oven

SPECIFICATIONS

| Product Being Processed | Cast components |

| Overall Dimensions | 23′-3″ L x 9’-6″ W x 11’-0″ H (7087mm x 2896mm x 3353mm) |

| Type of Heating System | Electric |

| Conveyor Width | 7′-7″ (2311mm) |

| Heating Zone Length | Zone-1 = 4′-2” (1270mm), Zone-2 = 3′-0″ (914mm) |

| Cooling Zone Length | 4′-2″ (1270mm) |

| Operating Temperature | 1112°F (600°C) |

| Max Temperature | 1562°F (850°C) |

| Part Production Rate | 45 seconds |

DESCRIPTION

The DTI-775 curing oven system cures automotive disk brake pads. This system is designed to work in conjunction with a four-press manual system to provide continuous curing capabilities.

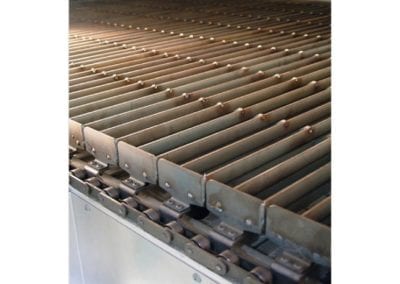

The formed parts are manually loaded from four individual presses to the oven tooling. Each press feeds two lanes in the oven, allowing eight parts to be processed together. This continuous operation oven is designed so that the product trays convey product through the oven in a vertical orientation.

AUTOMOTIVE SUPPLIER ADVANTAGES

- Elimination of batch processes and associated labor cost of handling product

- Reduces work in process

- Each part receives equal airflow resulting in shorter cure cycles as compared to cure cycles of parts being produced in baskets in a batch process.

- Shorter cycle times equate to less energy required for production

- Parts immediately entering cure oven reduces the required energy per part for cure cycle by utilizing heat absorbed by each part during press cycle

- Vertical part orientation reduces floor space required for the curing process in a work cell

AUTOMOTIVE OVEN FEATURES

- The oven is gas heated

- Custom product trays make up conveying system

- Heating and cooling in the same piece of equipment

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355