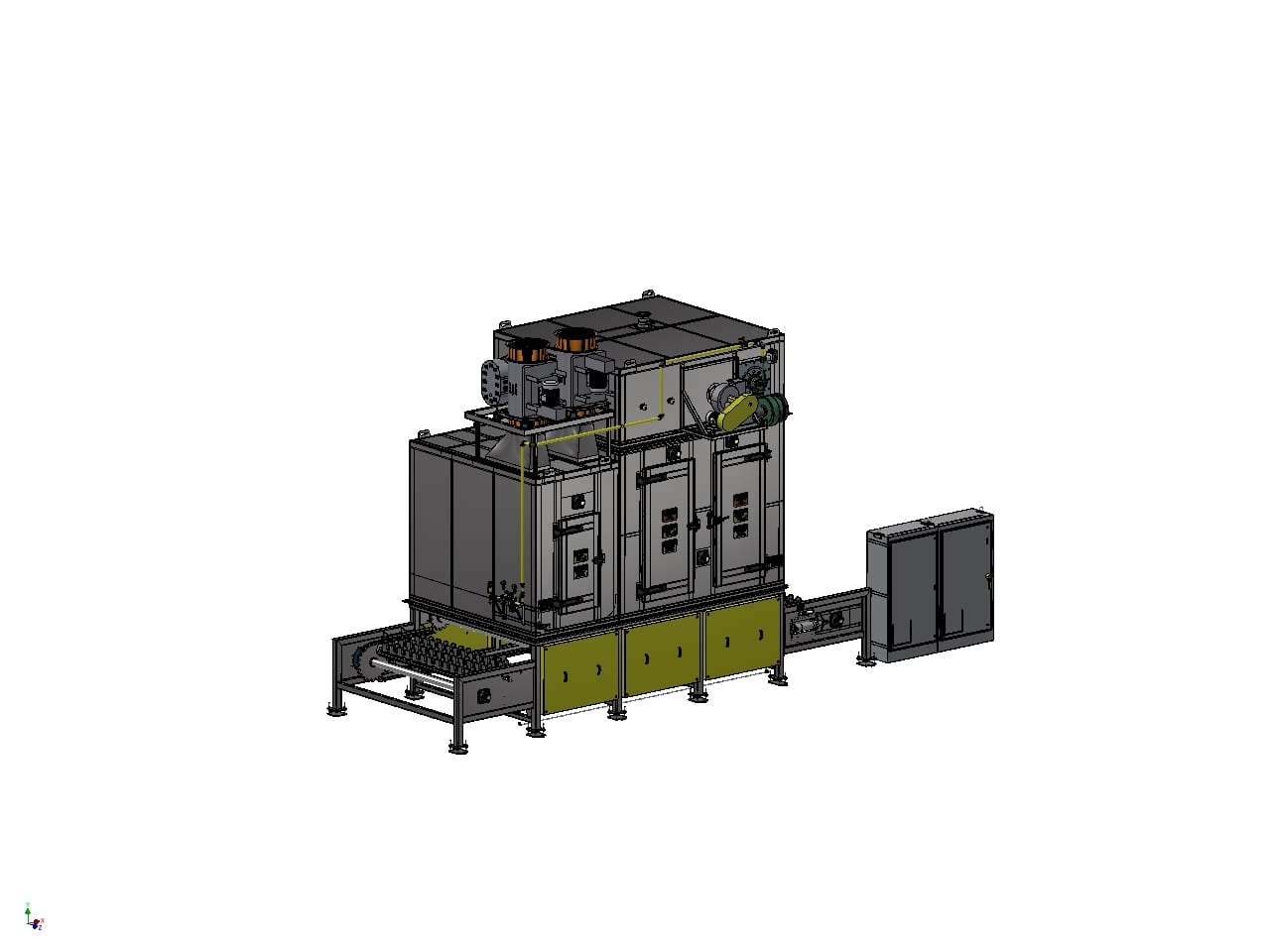

DTI-1392 Vertical Indexing Conveyor Oven

Customer directive

DTI-1392 was designed to be incorporated into a new manufacturing line and fit into a confined space within the customers’ existing building. The machine was designed to disassemble in pieces allowing the machine to be navigated through the building and assembled in place. Our machine provided a load position on the entrance end of oven and a unload position after the cooling section on the exit to interact with the customers automation and in line with their manufacturing line.

Description

Product is conveyed through the heating and cooling sections on swinging trays connected to oversize roller conveyor chain and large sprockets. Pneumatic grippers steady the trays in the load and unload position to ensure the tray is steady and in position while the automation loads and unloads the parts. Heating is accomplished with forced heated air convection followed by a cooling section with ambient air being forced across the parts, both horizontally. The control system includes PLC control of the oven temperature, fan speeds (oven, cooling, and exhaust), and an adjustable index timer, all of which can be used to change the amount of heating and cooling of the parts.

Specifications

| Product Being Processed | Automotive pistons |

| Overall Length, Width, Height | 25′-3″ L x 9′-7″ W x 16′-8″ H (7696mm x 2921mm x 5080mm) |

| Heated Chamber Length, Width, Height | 6′-11″ L x 8′-1″ W x 8′-0″ H (2108mm x 2464mm x 2438mm) |

| Type of Heating System | Modulating Natural Gas Fired Burner |

| Design Operating Temperature | 464°F (240°C) |

| Maximum Operating Temperature | 500°F (260°C) |

| Product Support | Swinging trays that allow the product to remain upright while traveling vertically through the machine |

| Controls | PLC controls with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures custom industrial ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Horizontal or vertical

- Industries Served: Automotive, pharmaceutical/medical, aerospace, manufacturing

- Materials Processed: Pistons, engine components, steel/aluminum castings, plastics, glass

- Other Processes: Baking, pre-heating, curing, drying, sintering, annealing

- Heating Systems: Gas, electric, hot oil