DTI-1135 Vertical Oven Curing System

DESCRIPTION

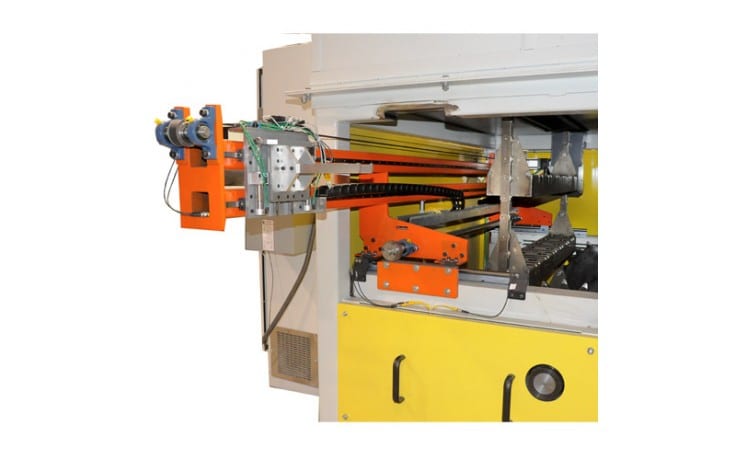

The DTI-1135 vertical oven cures a coating on steel components used in the automotive industry. The coating is applied to the exterior surface of the parts and the parts are then loaded into the oven via a pick and place system that is part of the oven design.

Parts are conveyed through the oven on custom product trays, attached to oven class chain, that make up the conveying system. Multiple parts are loaded across the width of each product tray and index through the oven in a vertical orientation. The control system provides the ability to adjust the index time of the conveying system to provide varying dwell times in the heated chamber.

Once the curing cycle is complete the parts travel horizontally through a cooling section located below the heated chamber and are cooled to a temperature safe for unloading.

SPECIFICATIONS

| Overall Dimensions | 16′-6″ L x 5′-10″ W x 15′-6″ H (5029mm x 1778mm x 4724mm) |

| Insulation Thickness | 4″ (102mm) |

| Heat Source | Modulating Natural Gas Burner |

| Maximum Temperature | 500°F (260°C) |

| Design Operating Temperature | 464°F (240°C) |

| Airflow | Horizontal Cross Flow |

| Fans | One (1) Circulation Fan, One (1) Cooling Fan, One (1) Cooling Exhaust Fan |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Controls | PLC with Operator Touch Screen (HMI) for all functions |

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous