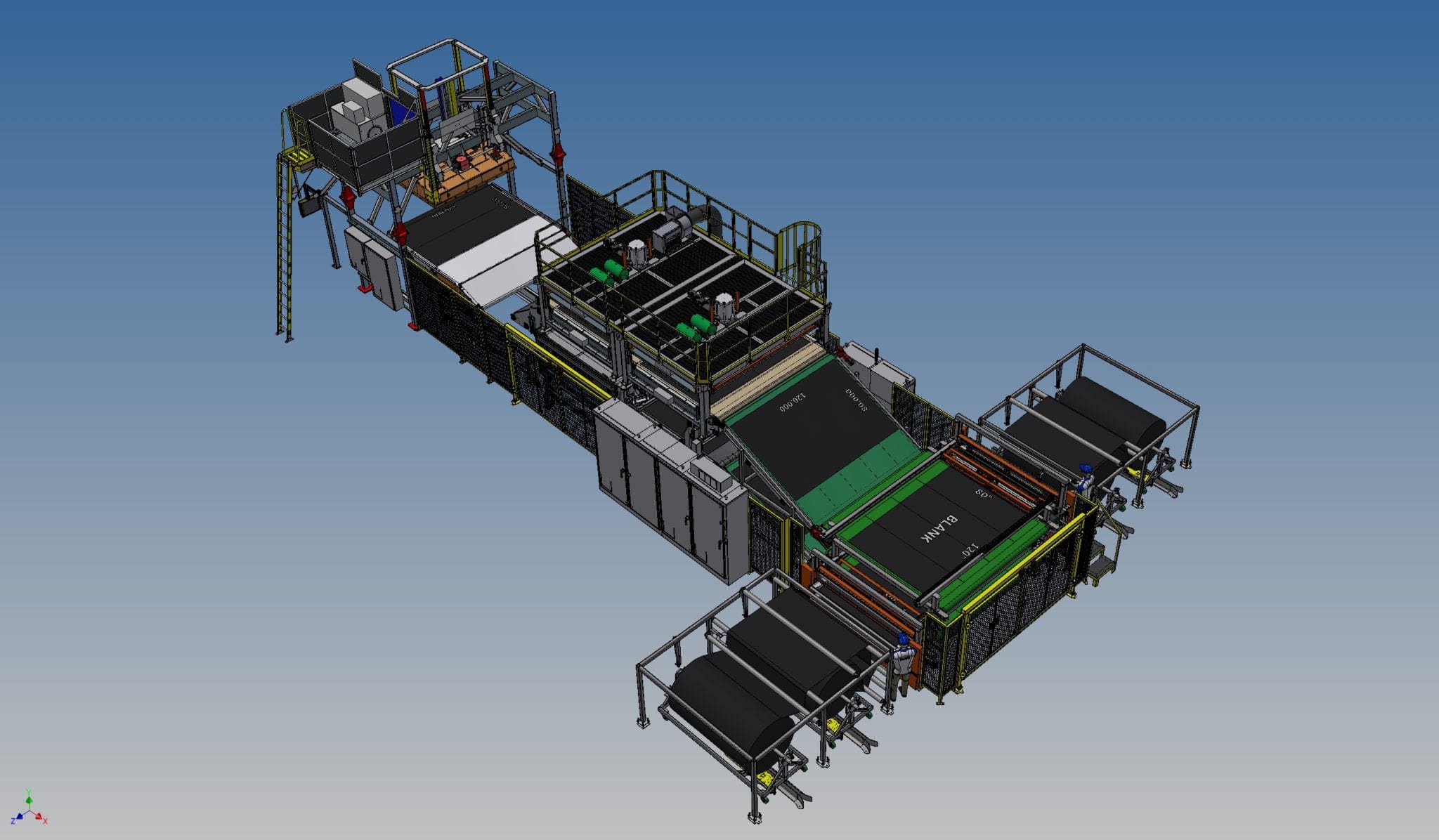

DTI-1340 Contact Heat-IR Oven Line

Customer directive

DTI-1340 was designed to eliminate the extra processing step of working from cut flat blank off materials. Aside from the extra time and money involved in using pre-cut blanks, the stacks of material themselves are rarely straight and often problematic due to their orientation. By pulling from two rolls of material, this system eliminates the need, structure, and alignment issues of a “pick and place” type load system. In roughly the same footprint, this roll system is able to provide consistent alignment, and a second roll of each material ready to seamlessly transfer into production, eliminating down time in roll changes and allowing the workers generous time to reload rolls.

Description

DTI-1340 is a stacked carpet preheat line that pulls two materials from rolls, cuts them to length and indexes them through two different heating processes. After heat, the two parts are then combined one on top of the other and shuttled into a press to be shaped. This line can produce a part every 60 seconds.

The in-feed has an automated system that pulls carpet and backing material perpendicular to process flow to load two new blanks into the system at a time. The materials are pulled from rolls on either side of the first conveyor set, through a clamping and cutting system. These material rolls are shifted by an auto-alignment system to accommodate up to 13” of misalignment in any given roll. It’s then cut to a touchscreen (HMI) specified length, and each is pulled to the center of its conveyor.

The stacked Pull to Length conveyors then feed the blanks up indexing conveyors to two stages of contact heat on a Teflon, non-stick conveyor, and through one stage of infrared heat. The pneumatic contact presses can generate pressing forces up to approximately 5000lbs to aid in quickly heating the indexed blanks. They are then very accurately combined on a shuttling conveyor that extends into the press tooling, and back feeds to allow a single operator to simply hold the leading edge as the materials are draped into the press tooling.

Specifications

| Product Being Processed | Automotive carpet and backing |

| Overall Length, Width and Height | 53′-6″ L x 43′-0″ W x 15′-0″ H (16310mm x 13110mm x 4570mm) |

| Heated Chamber Length, Width, Height | 7′-0″ L x 10′-2″ W x 1′-6″ H (2130mm x 3100mm x 460mm) |

| Type of Heating System | Infrared (IR) and electric contact heat |

| Designed Operating Temperature | 400°F IR, 300°-500°F contact heat (204°C IR, 149°C – 260°C contact heat) |

| Maximum Operating Temperature | 800°F IR, 500°F contact heat (427°C IR, 260°C contact heat) |

| Product Support | Teflon Belting Upper, Flat wire belting lower |

| Controls | PLC controls with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures custom industrial ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Vertical up or down, horizontal cross flow

- Industries Served: Automotive, aerospace, textile, non-woven,

- Materials Processed:

- Other Processes: Continuous web processes

- Heating Systems: Electric, natural gas or propane, thermal oil/water/glycol