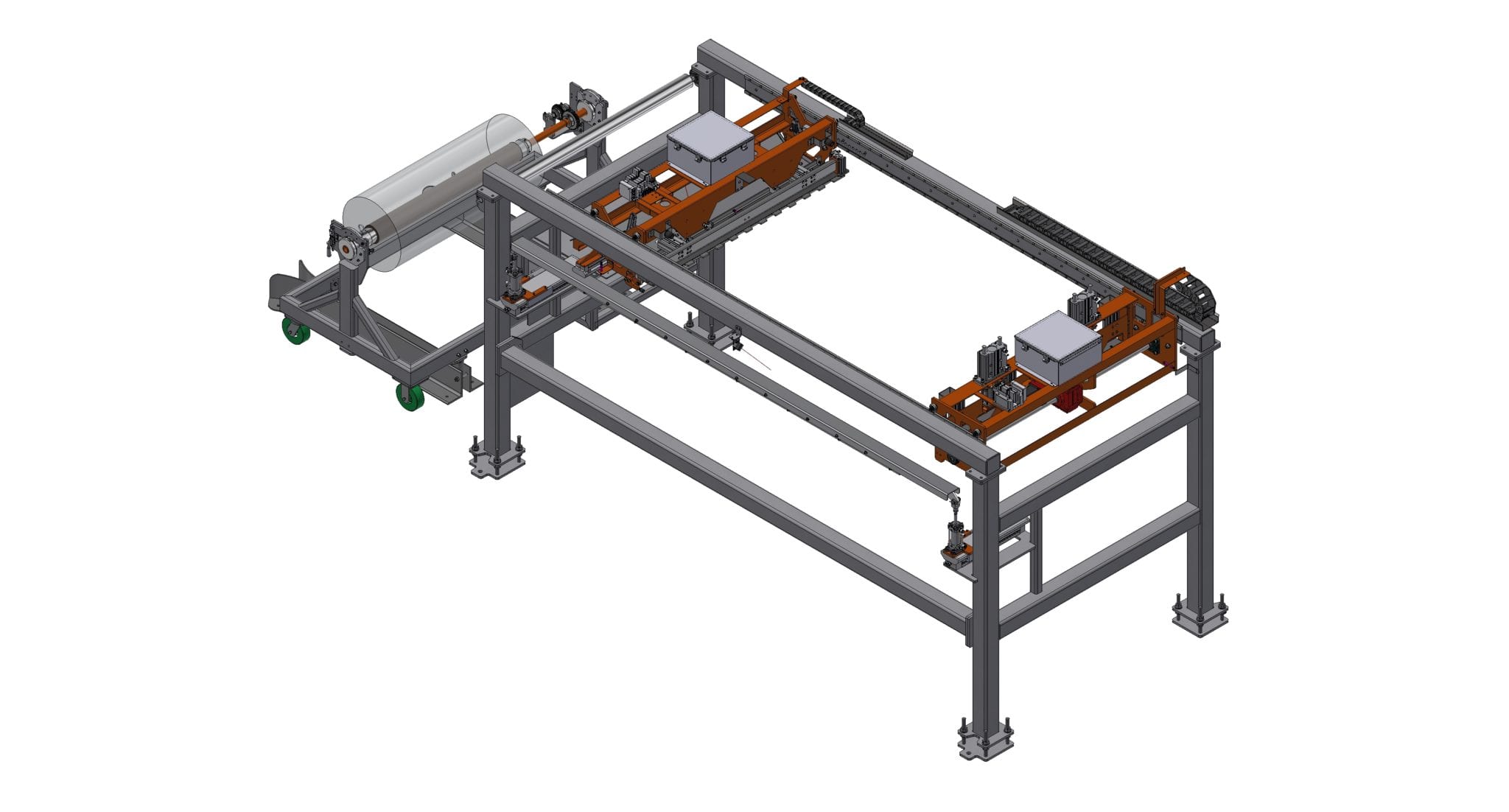

DTI-1401 Film Applicator

Customer directive

Our customer wanted an automated process to pull film from a roll onto an automotive acoustic product. The fill will be applied at a specified length that is entered into the HMI. The film applicator will lower film onto the product after exiting a DTI oven system, cut the film to length, and press the leading edge to adhere it to the part prior to shuttling out into a press. This entire process takes no more than 20 seconds in order to maximize the oven throughput. The customer also wanted the film roll to be supported by a mobile cart that could be transported to another location to replace empty rolls.

Description

DTI-1401 was designed to fit directly over an existing DTI oven shuttle conveyor for ease of installation. The machine consists of a structural steel frame, a pull-to-length carriage, a cross-cut carriage, and a film roll cart. The pull-to-length carriage was designed with pneumatically actuated gripper teeth to grab the film material. A servo motor moves the pull-to-length carriage towards the cross-cut carriage on linear rails to grab the material from the cross-cut carriage, clamp the material, and then pull film to the appropriate length. Both carriages are equipped with Pneumatic cylinders to lower the film down onto the product and a pneumatically actuated blade cuts the film. A heated bar presses the front edge of the product to compress and adhere the film to the product. This prevents the front edge of the film from being displaced during the shuttle conveyor’s travel out to the press. The film roll cart was designed with a spindle to support and center the roll. This allows for quick removal of the empty film roll and quick installation of a new film roll.

Specifications

| Product Being Processed | Film material used in automotive acoustic products |

| Length, Width and Height | 6′-3″ L x 17′-5″ W x 6′-8″ H |

| Max Film Length, Width | 4′-0″ L x 7′-3″ W |

| Product Support | Mobile Film Roll Cart |

| Controls | PLC control with operator HMI, UL listed control enclosure |