Vertical Ovens

World-Class Vertical Ovens

World-Class Vertical Ovens

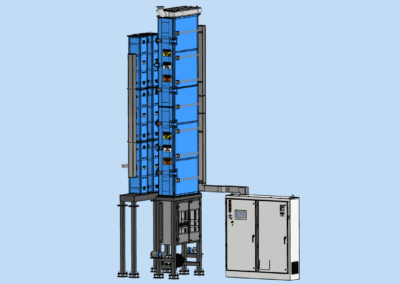

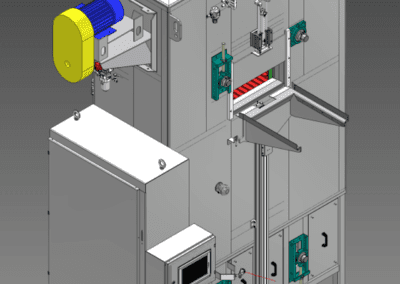

With over 100 years of combined experience, Davron designs and manufacturer’s vertical ovens in whatever combination the application requires with regards to width, length, and height. The main purpose of a vertical oven arrangement is to provide thermal processing while occupying a minimal amount of manufacturing floor space.

Our vertical ovens provide a long product dwell time in the heated chamber in a small footprint. Vertical ovens can be designed for multiple passes or a single pass, and can be loaded and unloaded on the same side or opposite sides of the oven.

Typically, products that lend themselves to this type of oven are small to medium in size. Larger products are harder to convey and the space savings are nullified due to the layout of the conveying system. Our vertical ovens feature structural steel frames internal to the insulated walls of the oven. This construction method provides an oven of undisputed quality that is energy efficient and extremely robust.

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355