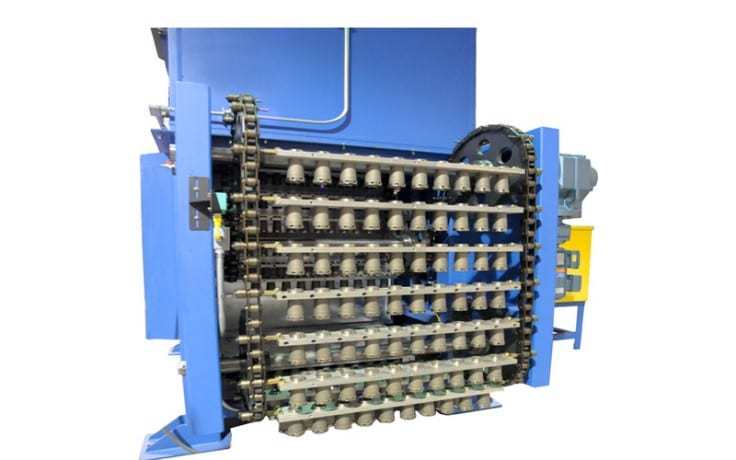

DTI-1028 Vertical Curing Oven

DESCRIPTION

The DTI-1028 vertical curing oven is used to cure carbon filters. The filters are loaded into custom fixtures and enter the heated chamber. The fixtures are indexed through the heated chamber in a vertical up and down orientation. The heated chamber includes 120 positions for heating. After the curing cycle is complete the fixtures exit the heated chamber and travel through the cooling section in a horizontal configuration. The cooling section utilizes ambient air for cooling and also includes 120 positions. After cooling the fixtures exit the cooling section and are unloaded.

SPECIFICATIONS

| Overall dimensions | 4′-6″ W x 21′-0″ H x 26′-6″ D (1372mm x 6401mm x 8077mm) |

| Insulation Thickness | 6″ (152mm) |

| Heat Source | Single full modulating natural gas burner package |

| Maximum Operating Temp | 500°F (260°C) |

| Design Operating Temp | 485°F (252°C) |

| Airflow | Horizontal cross flow |

| Circulation Fans | One (1) circulation fan, One (1) cooling supply fan |

| Exhaust Fans | One (1) exhaust fan, One (1) cooling exhaust fan |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Control | Digital indicating temperature and over temperature |

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous