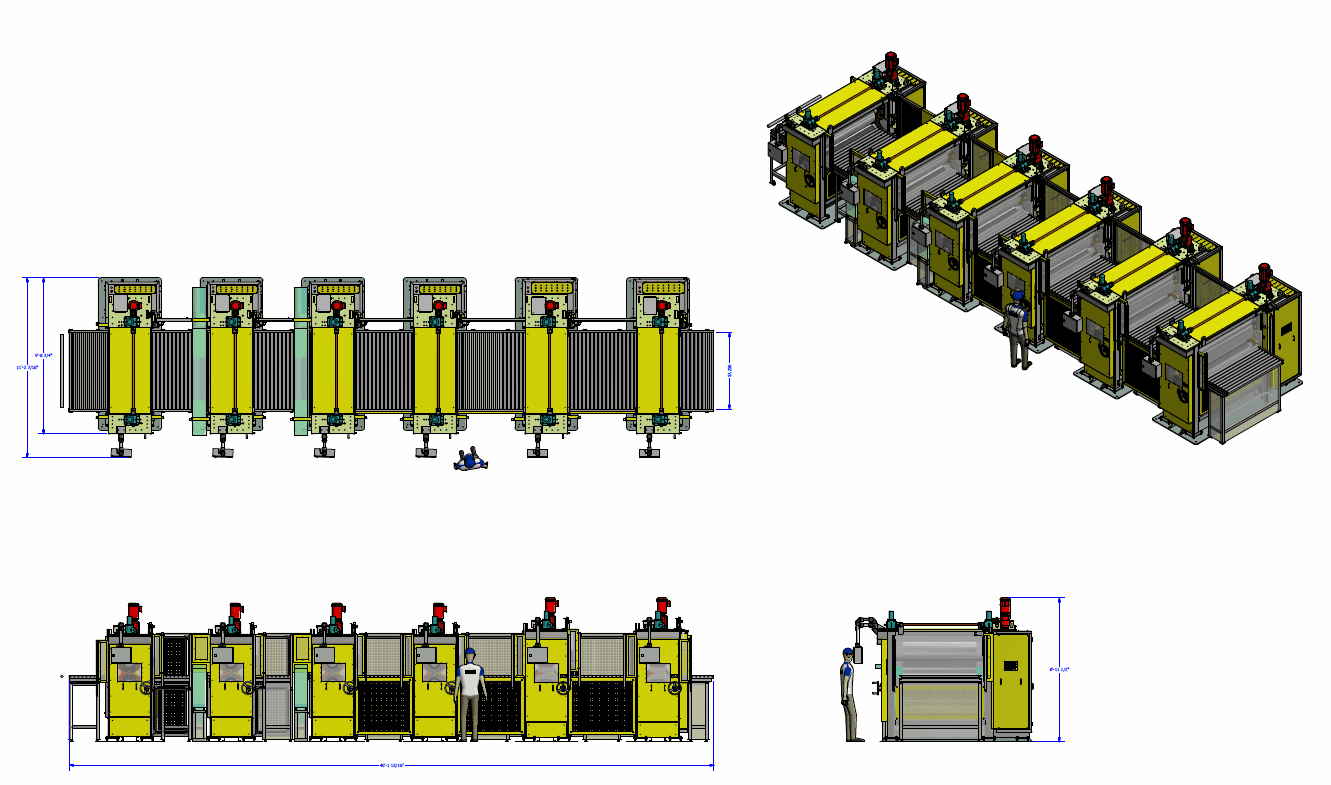

DTI-1286 Compression Roll Units

Customer directive

The intent of the project is to provide compression rolls to apply force to the foam web thickness during manufacturing. The system required multiple two-roll sets of rolls to progressively compress the foam web more as it passes through each set of compression rolls within the sequence. Six (6) rolls are required for this particular process to provide the required material compression. Each individual roll includes the capability to apply high force to the material. Each two-roll set is required to operate independently to provide variable speed capability to apply tension to the web length from roll to roll. Rolls can be chilled to cool the product if required.

Description

The Compression Roll system is a series of six (6) independent compression roll units. All units are aligned so that the foam web passes through all six during the manufacturing process. All six two-roll compression rolls operate independently. Each roll system includes variable speed operation for roll rotation. Rolls vary in size from 400mm to 600mm in diameter. All rolls are hard chromium plated, ground and polished for surface finish. Some rolls include chilled water circulation for cooling and others do not. Each roll system includes and independent structural framework with a gear reducer and electric motor to provide the proper torque for rotation during material compression. All roll systems includes an upper roll that will open and close to fixed positions for operation of loading materials. The upper roll is also connected to a rack and pinion system to maintain a parallel relationship to the lower roll at all times. All roll systems include a fixed location lower roll that includes gap adjustment to set roll gap. Gravity conveyors are included between the roll systems to transfer the foam web from roll to roll. All pinch points and machine access points are guarded with light curtains for operator safety.

The particular systems are part of a series of multiple machines included in this production line. The entire production line, including the compression rolls, are controlled by the overall PLC system we provided for the production line. All machine functions are controlled from multiple operator HMI’s (touch screens) at various locations along the line. Any machine included in the production line can be viewed and controlled from any HMI location.

Specifications

| Product Being Processed | Closed Cell Foam Products |

| Overall Length, Width and Height | 10′-0″ W x 9′-0″ H x 4′-0″ L (each roll system) (3050mm x 2740mm x 1220mm) |

| Roll Arrangement | Adjustable location lower roll, upper roll opens and closes by traveling vertically |

| Roll Alignment | Rack and pinion system to maintain parallel relationship between the rolls |

| Roll Rotation | Gear reducer with variable frequency drive for rotational speed adjustment |

| Roll Diameter | 400mm diameter and 600mm diameter |

| Roll Finish | Pre-ground, hard chromium plated, ground and polished for final finish |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

If your project requires similar equipment but with different operational parameters please contact us. Davron Technologies, Inc. designs and manufactures equipment similar to this type to meet many unique process requirements, including but not limited to, the following:

- Industries Served: Foam Products of all types requiring compression during manufacturing. Any continuous web product type or roll goods that require compression during the manufacturing process.

- Materials Processed: Various web foam products, materials that are coated and require pressure after the coating applications.

- Alternate Designs: Sized as required in regards to roll length and roll width. Various materials of construction. Any type roll process machines requiring rollers to apply pressure to the product to feed material. Other options include heat lamination processes, accumulation systems, pinch roll systems and cooling roll systems. Rolls can also be lagged with various materials for particular applications.

- Other Processes: Preheating, Curing, Cooling, Lamination, web drive pinch rolls between processes.