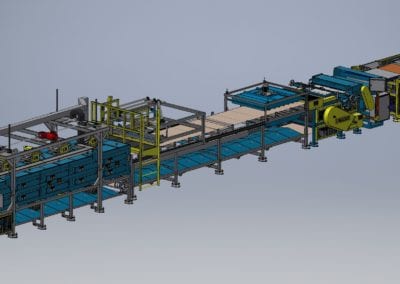

DTI-1407 Crosslink Conveyor Oven

SPECIFICATIONS

|

Product Being Processed |

Foam |

|

Overall Length, Width, Height |

69’-6” L x 8’-0” W x 10’-8” H (21184mm x 2438mm x 3251mm) |

|

Heated Chamber Length, Width, Height |

20’-0” L x 4’-4” W x 1’-9” H (6096mm x 1321mm x 533mm) |

|

Type of Heating System |

Electric Heater Rods |

|

Design Operating Temperature |

302°F – 410°F (150°C – 210°C) |

|

Maximum Operating Temperature |

500°F (260°C) |

|

Product Support |

Teflon belt on rollers, roller beds, smooth table tops |

|

Controls |

PLC control with operator HMI, UL listed control enclosure |

CUSTOMER DIRECTIVE

The customer requested an industrial oven system that cross links foam prior to expansion, cools the product, slits, shears, and then stacks the slabs. Ease of cleaning and maintenance was a priority for the heated section of the machine. The DTI-1407 industrial oven section is made of two halves of which the top half can be lifted vertically for access for cleaning and maintenance. A cooling conveyor provides forced ambient air to the top and bottom of the product. A slitter with adjustable blades determines part width and edge trim followed by a slitter that determines length of the part. The parts are then stacked onto a pallet to be removed by forklift.

DESCRIPTION

A constant stream of material is extruded onto the Teflon conveyor belt. The upstream conveyor belt roller can be extended up to 24” to meet the extruder head without changing the overall length of the belt. The conveyor moves the product through five zones of adjustable heat as cross linking takes place and then over a cooling conveyor where air is forced onto the top of the product and bottom of the belt to cool the extrusion before slitting and shearing to size. A thin film is applied to the extrusion prior to entering the oven by a pneumatically operated roller to prevent scorching during the heating process. Once the extrusion exits the oven the film is removed from the product, turned 90 degrees and then rolled up onto a core. The slitter hinges with air cylinders for threading or removing web material. Adjustable guides align the extrusion from either side prior to the slitting process. The slitter blades can be positioned for multiple cuts and variable width while the blade speed is set via one of the two HMI screens. An encoder wheel allows shear length to be set precisely for different production runs. Finally, a lift table and servo driven screw drive position a pallet for different stacking patterns depending on the size of the finished part.

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. designs and manufactures custom industrial ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Vertical top/down, horizontal either side

- Industries Served: Industrial Foam industry, web process, continuous extrusion

- Materials Processed: Industrial Foam, extrusions

- Other Processes: Heating, drying, curing, cross linking, bonding

- Heating Systems: Modulating gas fired direct or indirect, electric, thermal oil

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355