DTI-1286 Dual Oven System

Customer directive

The customer requested that we provide two multiple zone ovens to provide independent temperature control for each heated zone within each oven. The system also required that each heated zone include an independent conveyor that could operate at different speeds during process. This particular system utilizes thermal oil for process heating.

Description

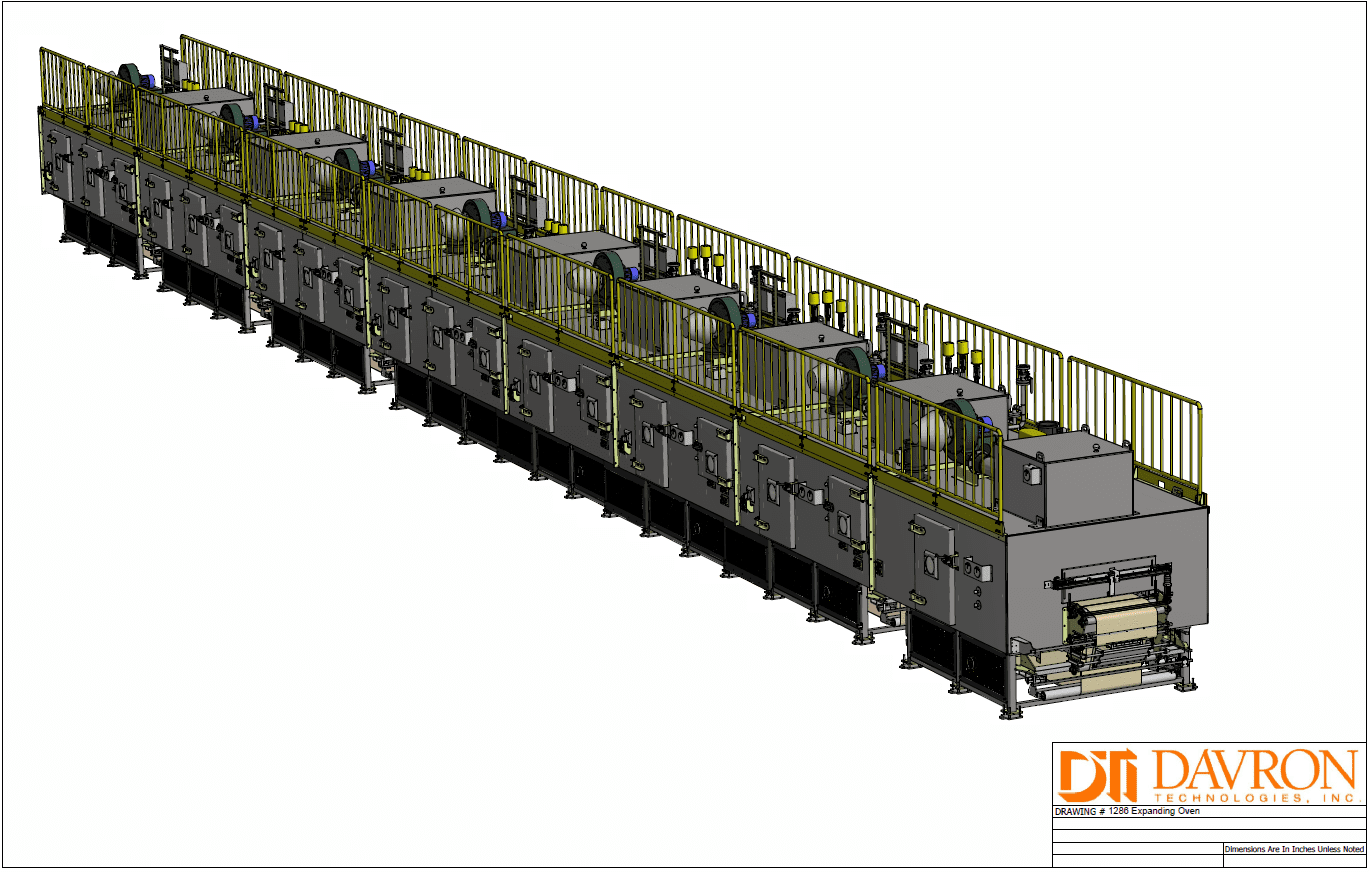

The DTI 1286 Expanding Oven is a multi-zone conveyor oven and includes eight (8) zones of independent temperature control. The DTI 1286 Cure oven includes three (3) zones. Each zone is heated by thermal oil circulated through heating coils located within the air circuit. Separate fans are included for each heated zone to circulate air within that zone. Each zone of the system includes an independent conveyor system to provide variable speed operation from zone to zone. Each individual conveyor system includes a Teflon coated belt, automatic belt tensioning, and an automatic belt tracking system. The individual heated chambers include three access doors on each side of each heated zone to provide access to the heated chamber. Each individual access door also includes a viewing window to allow the product to be viewed during operation without opening the door. The ovens were manufactured and shipped in modules to bolt together during installation. Each module includes a support frame with level adjustment and can be anchored to the plant floor. The ovens are built with our proprietary wall system and includes 6” insulation to provide energy efficiency as well as low external surface temperatures for operator safety. The ovens are fully assembled and factory tested for operational verification prior to shipment.

These particular ovens are two pieces of equipment operating in a series of multiple machines included in this production line. The entire production line, including these ovens, are controlled by the overall PLC system we provided for the production line. All machine functions are controlled from multiple operator HMI’s (touch screens) at various locations along the line. Any machine included in the production line can be viewed and controlled from any HMI location.

Specifications

| Product Being Processed | Closed Cell Foam Products |

| Expanding Oven Width, Height, and Length | 8′-4″ W x 10′-0″ H x 109′-0″ L (2540mm x 3050mm x 33220mm) |

| Cure Oven Overall Width, Height, and Length | 8′-4″ W x 10′-0″ H x 80′-0″ L (2540mm x 3050mm x 24380mm) |

| Type of Heating System | Thermal Oil |

| Designed Operating Temperature Range | 150”F – 430”F (65”C – 221”C) |

| Maximum Operating Temperature | 450”F (232”C) |

| Expanding Oven Number of Heated Zones | Eight (8) |

| Cure Oven Number of Heated Zones | Three (3) |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

If your project requires similar equipment but at different operating temperatures or sizes please contact us. Davron Technologies, Inc. designs and manufactures ovens similar to this type to meet many unique process requirements, including but not limited to, the following:

- Industries Served: Foam Products of all types for thermal process during manufacturing. Food Industry for continuous baking processes. Any continuous web product type that requires thermal processing during manufacturing.

- Materials Processed: Various web foam products including Polyolefin, Polyethylene, Copolymers, Fluoropolymers, and Elastomer based products requiring thermal processing. The system can also be used for many other types of products.

- Alternate Designs: Sized as required in regards to length and web width. Various materials of construction including various stainless steel alloys, or aluminized steel. Temperature ranges to fit your specific thermal requirements.

- Other Processes: Preheating, Curing, Drying, Solvent Drying, Bonding