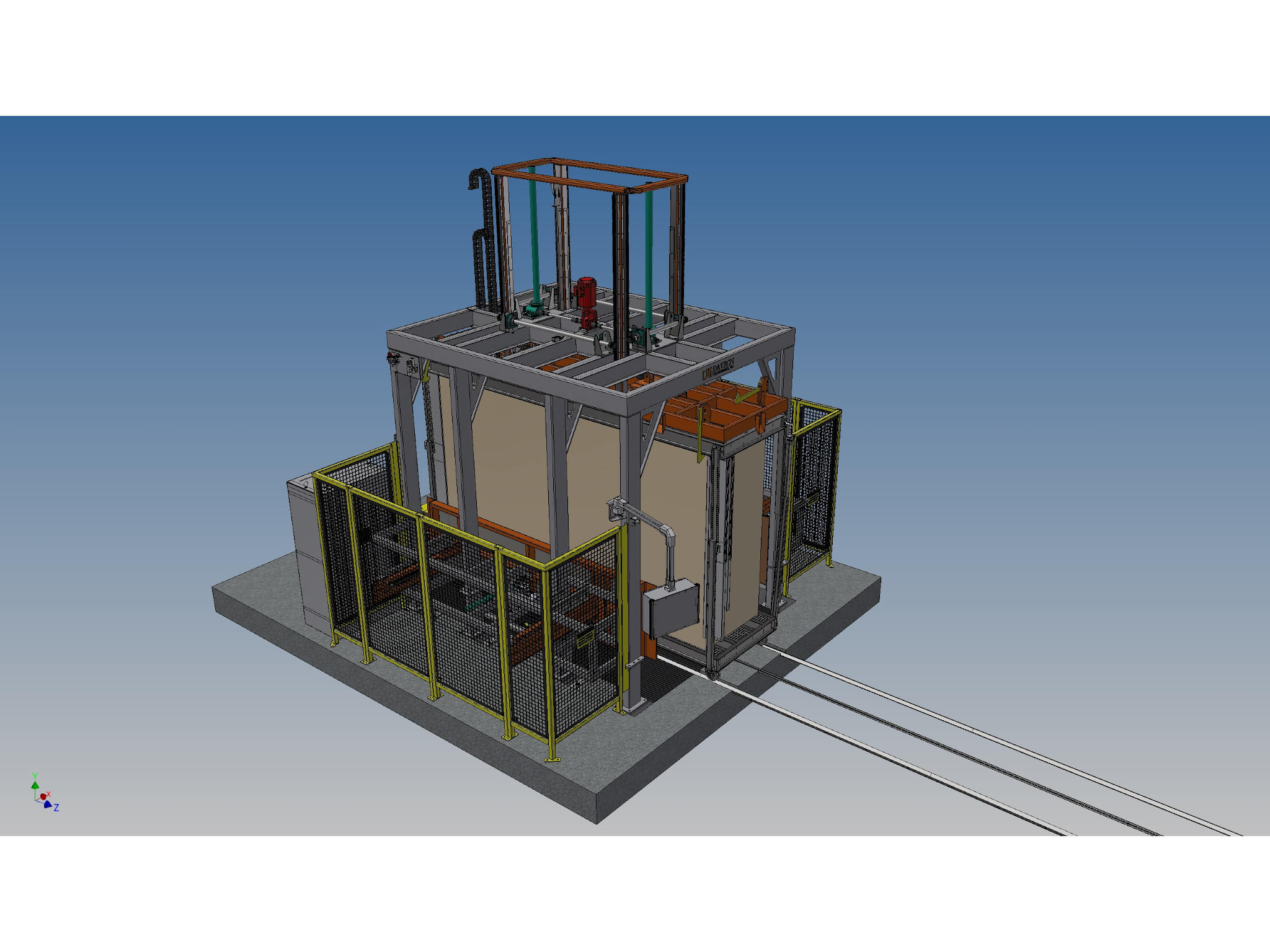

DTI-1363 Block Press

Customer directive

DTI-1363 was designed around the need to correct dimensional errors accrued in the manufacturing of the honeycomb composite material. The press is used to straighten any curvature that may exist along the length and height of the product, as well as to bring the material dimensions into adherence with production specifications. Once corrected the material is secured in the corrected posture and transported into a DTI oven system for curing. Due to space requirements for load/unload and existing machinery the press is located approximately 55 feet away. A cart and rail system is used to transport the material from the press into the oven. Due to the high traffic nature of the work area, there could be no restricting cabling, energy chains or festoons blocking the area during transport. To accommodate this, and to add to operator safety, a battery powered, wirelessly operated “tugger” was designed.

Description

The press features a vertical pressing ability up to 100KN as well as 25KN of opposing horizontal pressing ability. These three pressing platens are independently operated through the HMI touchscreen by the operator. The press frame incorporates a full below grade base that contains all the pressing forces generated. This eliminates the need for a special high tension concrete foundation. The cart framing interlocks with the upper press platen and incorporates a self-centering design to aid cart-to-press alignment. Floor scanners protect the pressing areas and prevent any machine motion while operators are in critical locations. Once the honeycomb structure has been reshaped and pinned in position, the operator uses the tugger’s wireless remote controls to push the cart from the press about 55 feet into the cure oven in approximately 1 minute. The tugger utilizes electric latches also operated conveniently from the remote control, to unlatch from the cart after parking it in oven.

Specifications

| Product Being Processed | Honeycomb composite material used in the aerospace industry |

| Overall Length, Width and Height | 19′-0″ L x 17′-2″ W x 16′-10″ H (5790mm x 5230mm x 5130mm) |

| Product Maximum Length, Width, Height | 13′-2″ L x 3′-4″ W x 7′-7″ H (4010mm x 1020mm x 2310mm) |

| Product Support | Fully stainless steel, multipurpose cart and battery operated, wirelessly controlled cart tugger |

| Controls | PLC controls and safety sensors, HMI operator station for manual adjustment |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures custom industrial ovens to meet many unique process requirements, including but not limited to, the following:

- Industries Served: Aerospace, Catalyst Manufacturing/Regeneration, Automotive, Transportation, or any industry that requires material manipulation prior to or after a heating process.

- Materials Processed: Particularly any Honeycomb or Cellular type product. The press /cart system can also be used for many other types of products and can be designed in any size required.

- Other Processes: Bonding, stretching, pressing, reshaping, or other dimensional corrections before curing, drying or after any type of heat setting process.

- Potential Heating Systems to Incorporate: Electric or Thermal Oil.