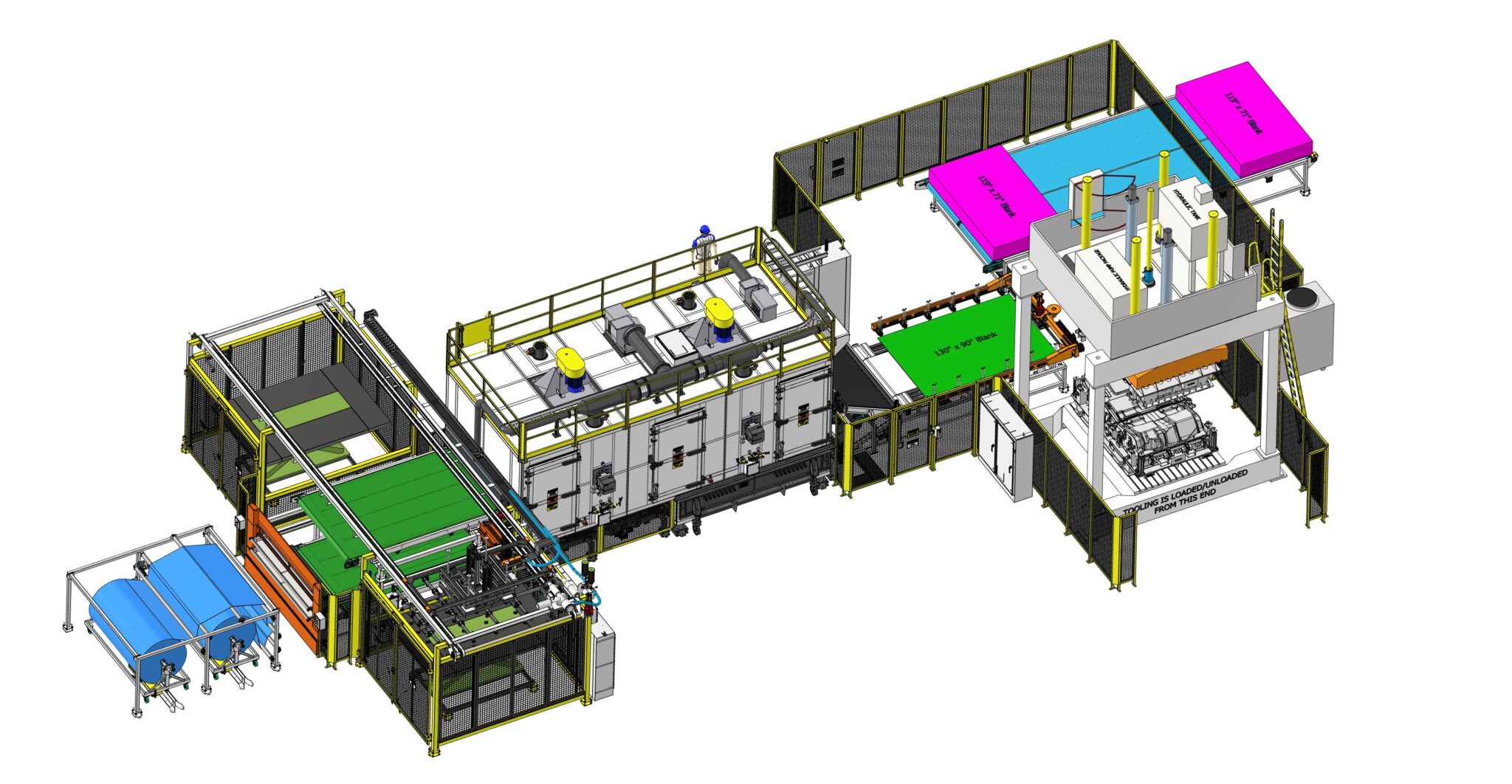

You’ll need the perfect production line to go with it.

Nobody’s manufacturing line consists of a standalone oven. Even your street corner bakery will have a mixing station and speed racks for cooling loaves down.

Modern manufacturing facilities achieve process control through intentionally designed equipment up and down their line, from part prep to conveyance to accumulation and packaging.

Your production line is only as efficient and effective as your least functional piece of equipment. Historically, manufacturers call on us when their oven is that sore spot on their line. But we’ve grown to handle more complicated projects, including full production lines.

Why? Because installing a line of purpose-built equipment presents manufacturers with an integration challenge we know we can handle.

The challenge of equipment integration

Surrounding your custom oven with built-to-spec processing equipment from a variety of OEMs is easier said than done. For one thing, setting the equipment down in your facility is just the beginning.

If you’re assembling a production line with equipment from a variety of sources — like most facilities do — then you’ll need to integrate all that equipment, or you’ll have hitches in your process.

You can put your internal team to work programming PLCs and tinkering with mechanical handoffs. Or you can hire a third-party integrator to come in and get your equipment playing nice together. Either way, you’ll have unusable equipment lying on your production floor for weeks, if not months, waiting on the last screws to tighten.

Sourcing equipment from multiple OEMs increases the challenge in getting your whole line speaking the same language. Pre-processing equipment that wants to run a Mitsubishi PLC, a drying oven programmed with Allen Bradley and Siemens-based post-processing equipment offer a communication challenge in integration.

On top of that, strong process control requires perfect mechanical handoffs, down to the millimeter. In the end, getting it right is always a tedious battle.

We want to simplify it for you. Just bring us your process parameters, and we can handle design, build, integration, testing and installation. Of an entire production line, if necessary.

Our approach to equipment integration

Armed with an understanding of what you need to achieve and purpose-built equipment to achieve it, we’ll set out to integrate equipment for smooth, inch-perfect handoffs.

That takes the right equipment in exactly the right place, and exactly the right communication between the equipment.

First, our mechanical engineers design the equipment and determine where sensors need to be located, and what actions they need to trigger elsewhere in the system. Once the part has reached a certain point on the conveyor, maybe oven doors need to open. Maybe a robotic arm needs to move to pick the part up and position it for forming.

Once the mechanical engineers have mapped out what needs to happen, they hand the plans over to the electrical engineers, who draw up wiring schematics to power and program the equipment.

When it comes time to turn the equipment on, both teams work together to fine-tune the equipment’s operation until we meet every process specification.

Building up to full speed

At first, we aim for the smoothest handoffs possible, usually at low speed. Then, gradually, we make the equipment move faster, until we’ve reached your target throughput with clean handoffs between equipment.

And every time we increase the speed of the system, we manage every little detail. Sometimes this means changing some programming or tinkering with acceleration. If a conveyor accelerates a part too quickly it could slip on the belt. Maybe rapid deceleration faults a drive. We work out these kinks while we bring the system up to speed.

When we’re confident that the system runs flawlessly at speed, we bring you out to our facility for factory acceptance testing (FAT). When we set up the equipment in your facility, it will already be integrated and tested. This shrinks the time from delivery to startup.

Need help with more than just an oven?

We’re happy to talk through a rough concept or detailed specifications. Whether you’re looking for a complete new line or just replacing bits and pieces of one, we handle more than just custom oven builds.

And it isn’t just integration. We’ll design the system, build each component in house (or spec out what we can’t build), assemble, test and integrate in house. All you have to do is bring us your process parameters. If they’re achievable within the laws of physics, our team can engineer and deliver your ideal system.

We’ll start by making some rough drawings and proving out a concept with pre-engineering, if needed.

Reach out to us here.