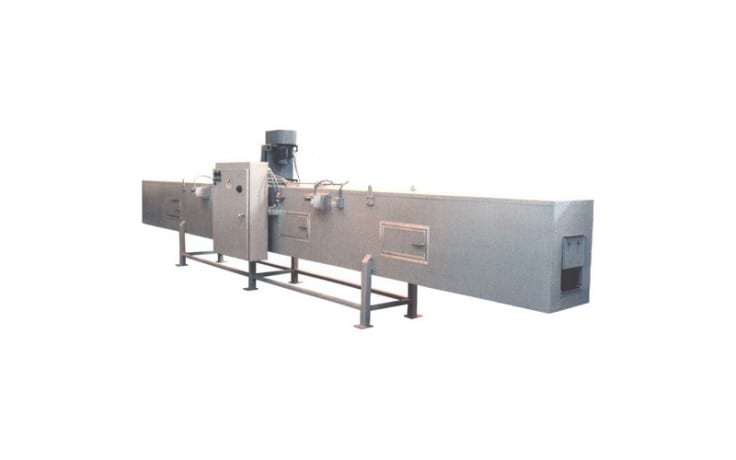

DTI-7942 Tunnel Preheat Oven

SPECIFICATIONS

| Chamber External Dimensions | 28′-0″ L – 1′-10″ W x 3′-0″ H (8534mm x 559mm x 914mm) |

| Conveyor Usable Size | 27′-8″ L x 1′-1″ W x 0′-6″ H (8433mm x 330mm x 152mm) |

| Insulation Thickness | 2″ (51mm) |

| Oven Conveyor Extensions | N/A |

| Conveyor Type | Existing |

| Conveyor Control | N/A |

| Heat Source | SCR controlled electric heater |

| Design Operating Temperature | 100°F – 150°F (34°C – 66°C) |

| Max Operating Temperature | 200°F (93°C) |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Controls | Closed Loop Digital Temperature Controller |

DESCRIPTION

The DTI-7942 conveyor oven is used in the automotive industry to preheat molds prior to injecting urethane into them to form a finished part. Empty molds are placed on the oven conveyor and pass through the oven to preheat. Upon reaching the exit of the oven, the molds are filled with a multiple component urethane mix and placed in the cure oven. This oven is electrically heated and provides a horizontal air flow within the chamber.

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355