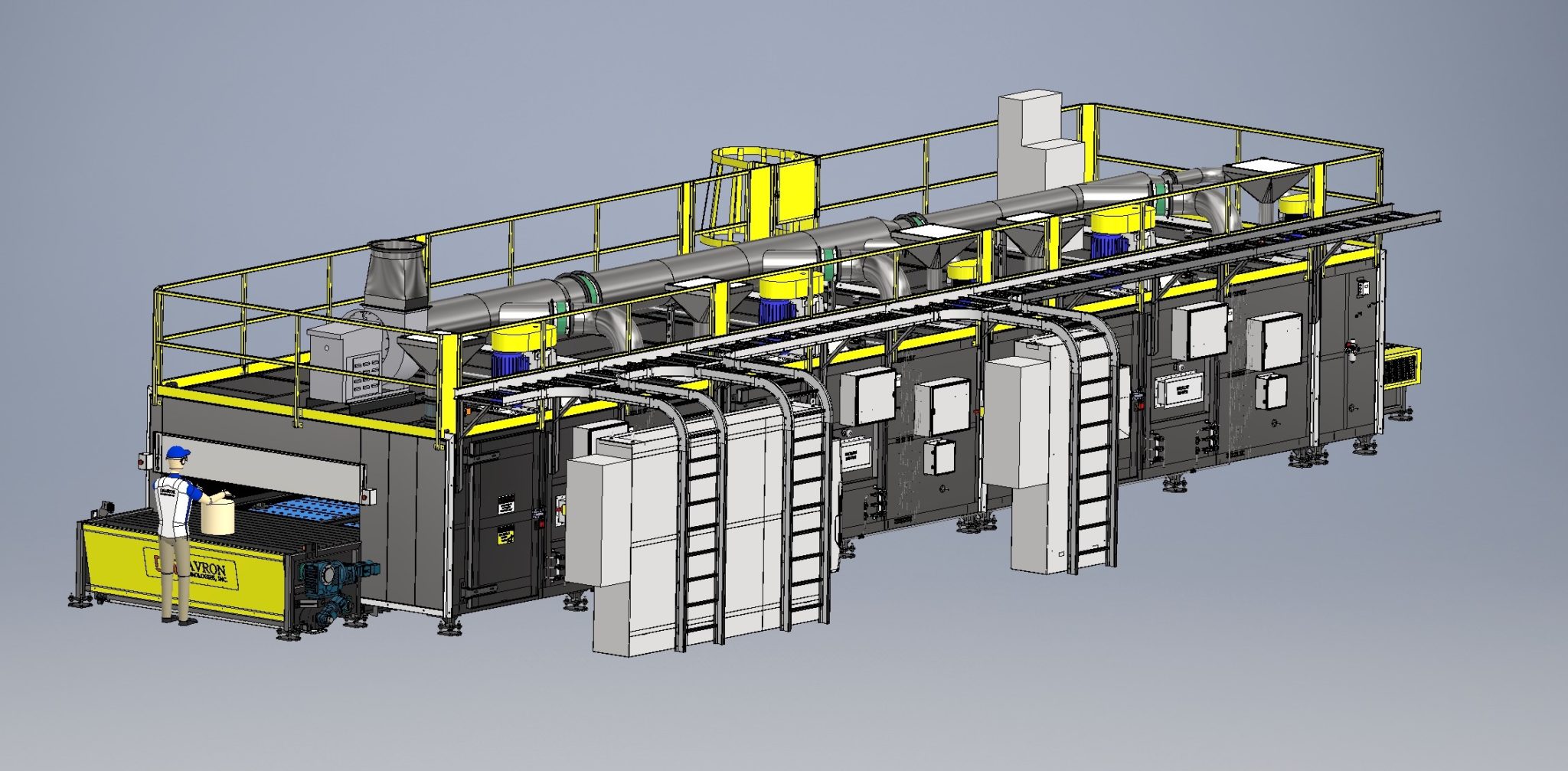

DTI-1462 Drying Conveyor Oven

SPECIFICATIONS

| Product Being Processed | Ceramic Substrates, Particulate Filters |

| Overall Equipment Dimensions | 57′-0″ L x 17′-0″ W x 10′-0″ H (17374mm x 5182mm x 3048mm) |

| Heated Chamber Dimensions | 47′-4″ L x 8′-4″ W x 2′-8″ H (14427mm x 2540mm x 813mm) |

| Type of Heating System | Electric Heaters |

| Design Operating Temperature | 95°F – 175°F (35°C – 79°C) |

| Maximum Operating Temperature | 175°F (79°C) |

| Product Support | Formed and coated slats on oversize roller attachment conveyor chain |

| Controls | PLC control with operator HMI, UL listed control enclosure |

CUSTOMER DIRECTIVE

This customer is a global technology company that specializes in specialty glass, ceramics, and related materials and technologies used for industrial and scientific applications. The product being dried in this application are ceramic substrates used in emission control systems. The product characteristics dictate a vertical top down airflow, as well as temperature and humidity control throughout the process. Conveyor extensions on the entrance and exit ends accommodate an automated loading process and a manual unloading process. Differential pressure transmitters mass air flow and velocity sensors provide process air feedback to correlate to existing machinery.

DESCRIPTION

Custom designed and coated conveyor slats convey the substrates through the oven. The slats allow vertical top down airflow to dry the part and the coating prevents any damage to the part. Multizone humidity and temperature control dry the part at a controlled rate to prevent cracking of the ceramic product. Differential pressure transmitters are used to control the mass flow rate of air across the product. A rotary brush on the exit end cleans any debris that might stick to the conveyor slats, and a pneumatic take up on the entrance end maintains proper tension on the conveyor to account for thermal expansion.

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Horizontal or vertical

- Industries Served: Automotive, industrial

- Materials Processed: Ceramics

- Other Processes: Baking, pre-heating, curing, crying, sintering, annealing

- Heating Systems: Gas, electric, thermal oil

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355