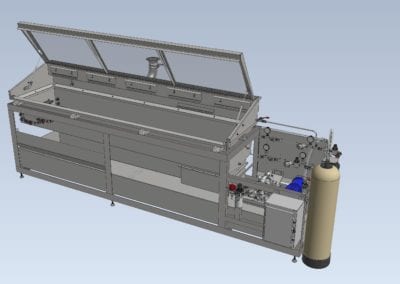

DTI-1457 Flushing & Drying Chambers

SPECIFICATIONS

| Product Being Processed | Medical Tubing |

| Flushing Chamber Overall Dimensions | 12′-5″ L x 4′-1″ W x 4′-10″ H (3785mm x 1245mm x 1473mm) |

| Flushing Chamber Interior Dimensions | 8′-9″ L x 2′-0″ W x 0′-10″ H (2667mm x 610mm x 254mm) |

| Drying Chamber Overall Dimensions | 1′-6″ L x 3′-1″ W x 8′-10″ H (457mm x 940mm x 2692mm) |

| Drying Chamber Interior Dimensions | 1′-2″ L x 2′-0″ W x 7′-6″ H (356mm x 610mm x 2286mm) |

| Product Support | Manifold |

| Controls | PLC control with operator HMI, UL listed control enclosure |

CUSTOMER DIRECTIVE

As Davron was developing a large oven system for this client, the customer realized Davron’s manufacturing ability did not end with ovens. This manufacturer had an acid flushing and drying process downstream of the oven system that was made up of old, mismatched, equipment needed to be replaced with purpose-built machinery, designed to fit their exact processing needs. After spending time with the customer and in their facility observing the process and asking lots of questions, Davron designed and built two complete machines. The flushing chamber is designed to flow an acid solution through the client’s small diameter tubing product, followed by a de-ionized water rinse. The tubing is then hung vertically in the drying chamber and blown dry with compressed nitrogen.

DESCRIPTION

The caustic nature of the acid meant everything in and on these two machines had to be stainless or highly corrosion resistant. The stainless chamber features a large flip-up lid with oversized viewing windows, angle adjustable product bed, minimized whetted surface areas, de-ionized water spray nozzle, and an integrated adjustable plenum and exhaust hood. The product bed utilizes innovative removable bars to allow operators access to the product and rinse fluids at regular intervals along the product bed. Davron designed the flushing system to have 2 separate manifolds, an acid and a water manifold, to ensure separation of the two fluids. A de-ionizing bed, DI-water meter, flow controls and a stop/start solenoid control the water circuit, while a purpose-built pump, flow control and stop/start solenoid supply acid to the acid manifold. Back pressure/flow preventers and pressure relief valve help to add safety to the pumping circuit. An air-operated dual diaphragm (AODD) pump removes the waste acid and water mixture to a neutralization tank.

Once flushed and rinsed the tubing product is then hung vertically from a manifold inside the drying chamber, where compressed nitrogen blows in the inner diameter dry and an air knife serves to remove moisture from the outside. Several of the customer’s tubes are up to 8ft in length, requiring the manifold to be mounted high out of reach of the operator. Davron devised a pneumatic system that raises and lowers the manifold approximately 30” to allow the tubing to hang without touching the bottom of the chamber. The manifold can be stopped at any point in the 30” travel. The bottom of the drying chamber houses a stainless drip pan that can be emptied if excess water builds up. A full length vertically hinged door allows for convenient operator access, while an adjustable exhaust system removes any potential fumes or excess moisture.

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Horizontal crossflow, vertical/top down

- Industries Served: Medical, Pharmaceutical

- Material Processed: Medical tubing

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355