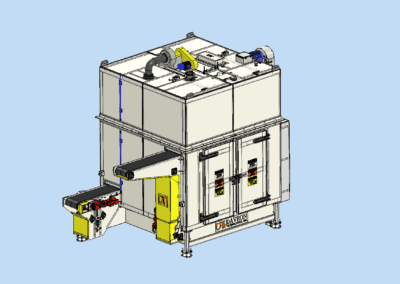

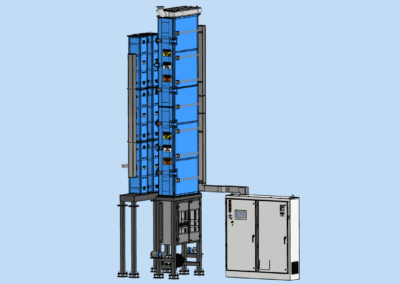

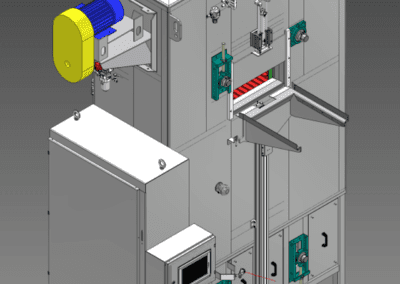

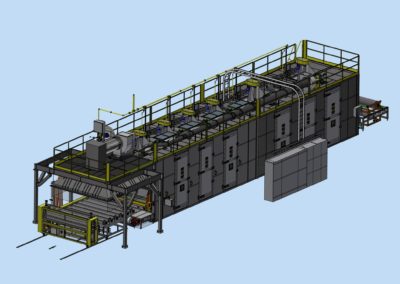

Curing Ovens

Precision Custom Curing Ovens Made in America

Davron’s curing ovens are designed to provide a consistent and extremely accurate temperature profile throughout the curing chamber from cycle to cycle. The end result is perfectly cured product from the first cycle to the last.

Davron exists to be the industry leader in non-standard products engineered to meet the customer's need and unique process.

Address

4563 Pinnacle Lane

Chattanooga, TN 37415

Phone

423-870-1888

info@davrontech.com

Fax

423-870-3355