DTI-1388 Drying Conveyor Oven

Customer directive

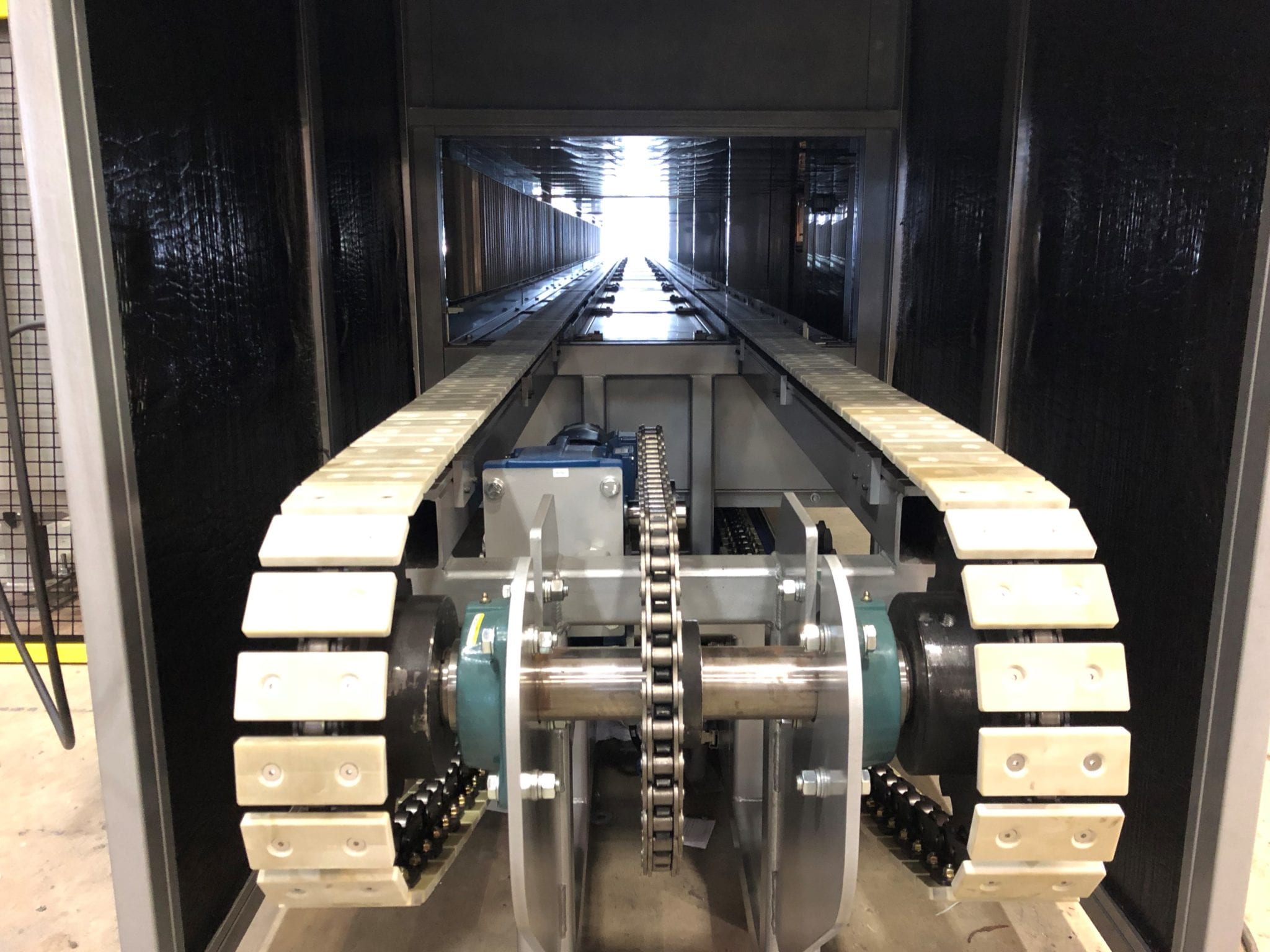

DTI-1388 was designed to remove water from a dense, yet porous, ceramic product. The dryer utilizes extremely high velocity airflow to force air through the product, thus removing water. A byproduct of this process is an organic oil that mixes with the water vapor. The product conveyed through this dryer cannot come into contact with metal at any time during the process. Because of this, the dryer utilizes a custom designed non-metallic high temperature conveying system.

Description

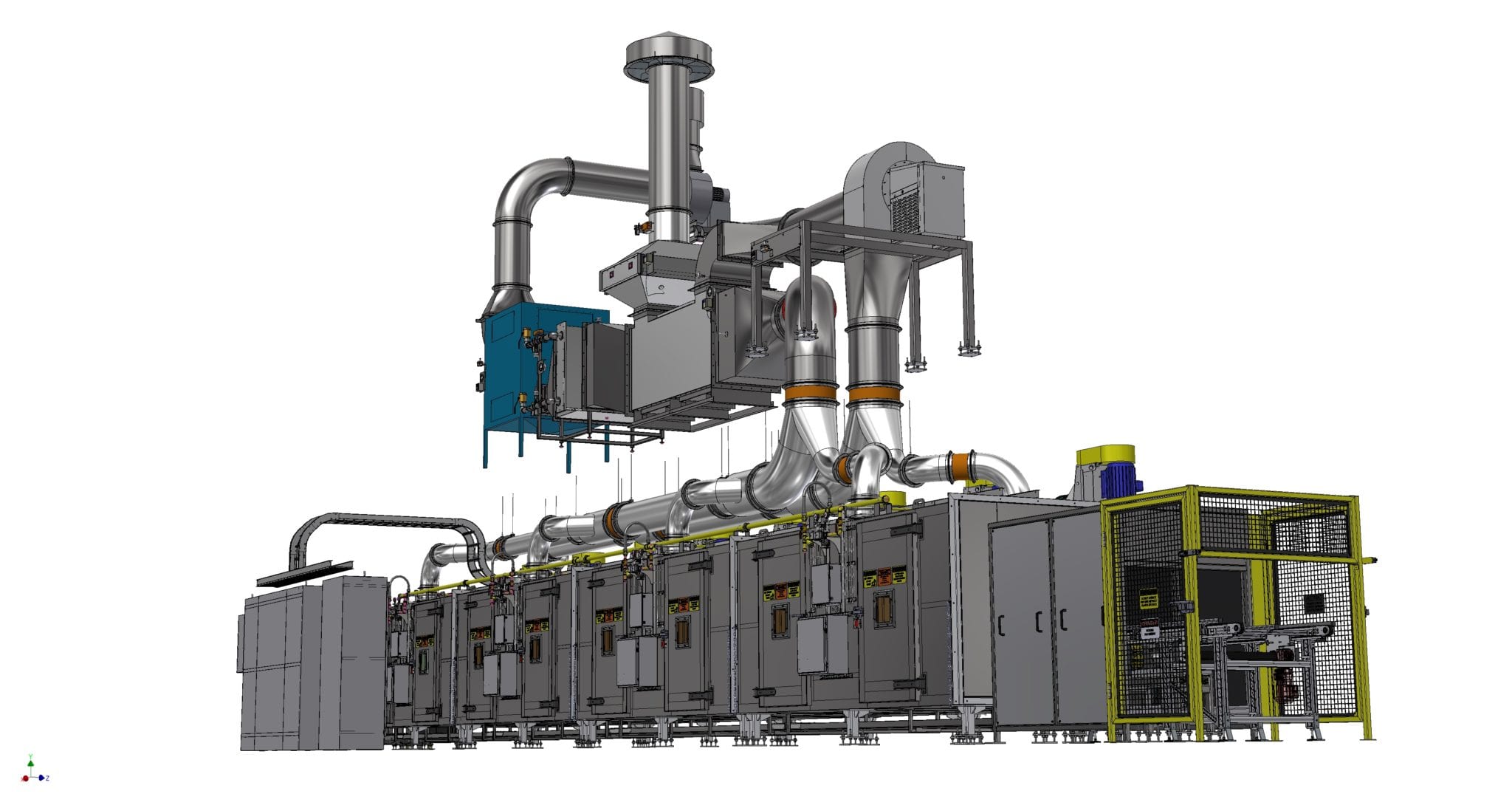

DTI-1388 consists of four zones of heat with each zone containing one natural gas burner and two circulation fans. The water/oil vapors are condensed and reclaimed at the air-to-air heat exchanger, followed by a condensing coil, and lastly a mist eliminating filter box. The air-to-air heat exchanger preheats the makeup air while helping to condense the byproducts in the exhaust air. This is also a multi-level system. The dryer and product conveyor are at ground level, while the supply fan, heat exchanger, condenser, intake and exhaust filter are located above on a mezzanine. The exhaust fan is mounted on the building roof above, outdoors.

Specifications

| Product Being Processed | Ceramics |

| Overall Length, Width, Height | 76′-0″ L x 11′-6″ W x 7′-6″ H (23165mm x 3505mm x 2286mm) |

| Heated Chamber Length, Width, Height | 60′-0″ L x 11′-6″ W x 7′-6″ H (18288mm x 3505mm x 2286mm) |

| Type of Heating System | Natural Gas |

| Design Operating Temperature | 265°F (129°C) |

| Maximum Operating Temperature | 300°F (149°C) |

| Controls | PLC controls with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. can design and manufactures custom industrial ovens and other thermal process equipment to meet many unique process requirements, including but not limited to, the following:

- Industries Served: Automotive

- Materials Processed: Ceramic

- Other Processes: Drying, Curing, Pre-curing