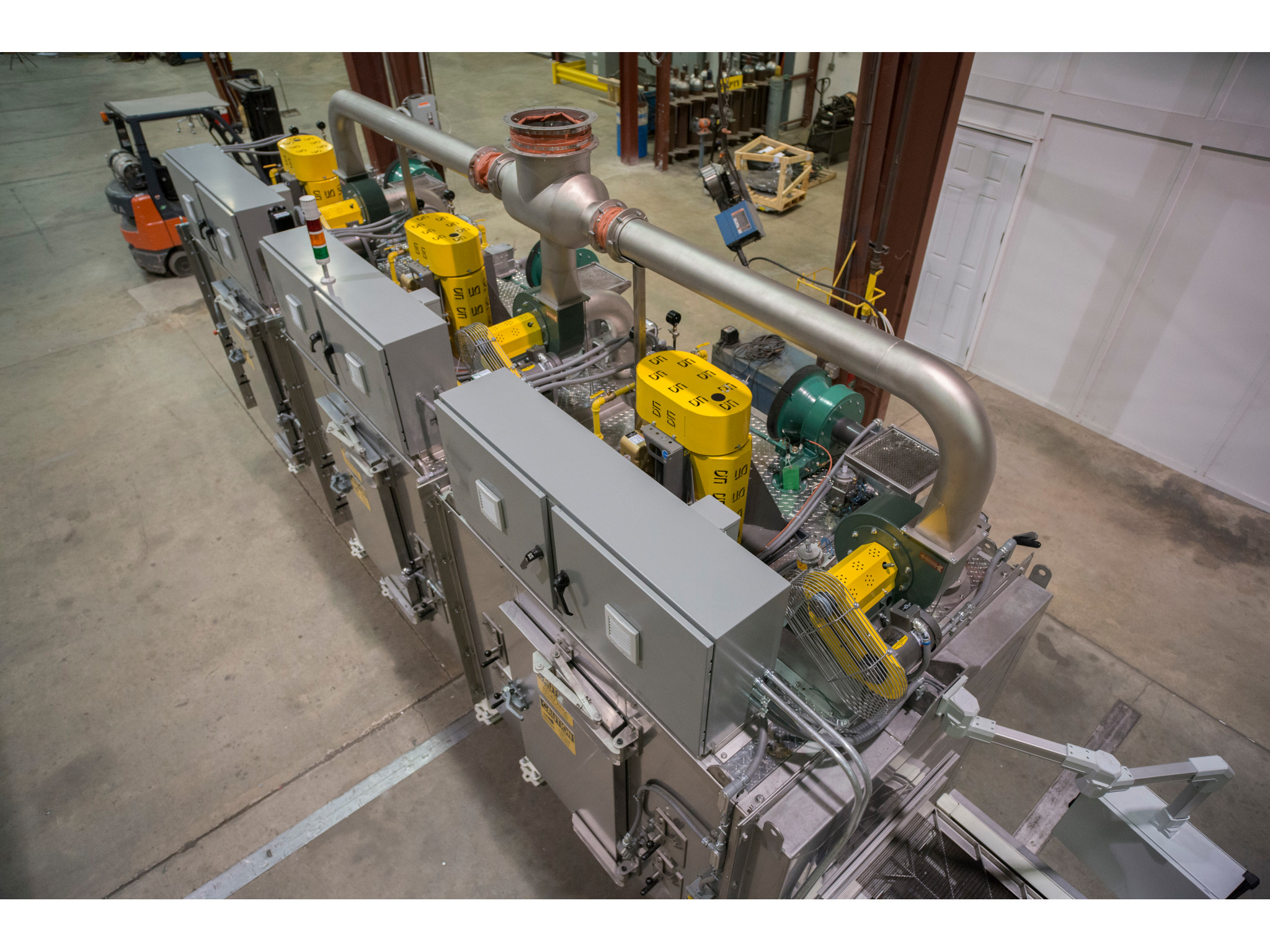

DTI-1354 Baking Conveyor Oven

Customer directive

The customer needed a continuous conveyor oven for testing and small production runs with the ability to increase to full production if necessary. DTI-1354 was designed as a modular system with three zones of heat and the capability to add additional zones as needed to meet production requirements.

Description

Conveyor speeds, fan speeds, and temperatures are set on the HMI touch screen and controlled through the PLC. Unbaked dough is extruded onto the stainless wire mesh belt and baked on its way through the three zones of heat. Heated air is directed at the product vertically from above and below the belt, while manual externally adjustable dampers bias the air flow top and bottom to produce an even bake and color.

Specifications

| Product Being Processed | Food/Cookies |

| Overall Length, Width, Height | 29′-3″ L x 5′-9″ W x 9′-8″ H (8915mm x 1753mm x 2946mm) |

| Heated Chamber Length, Width, Height | 19′-9″ L x 4′-3″ W x 4′-3″ H (6020mm x 1295mm x 1295mm) |

| Type of Heating System | Modulating Natural Gas Fired Burner |

| Design Operating Temperature | 250°F – 450°F (121°C – 232°C) |

| Maximum Operating Temperature | 500°F (260°C) |

| Product Support | Stainless steel wire mesh belt |

| Controls | PLC controls with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures custom industrial ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Vertical top or bottom, horizontal either side

- Industries Served: Automotive, food and beverage, aerospace, industrial foam

- Materials Processed: Automotive acoustics, carpets, foams,

- Other Processes: Baking, curing, drying, preheating

- Heating Systems: Modulating gas fired direct or indirect, electric, thermal oil