Case study: The making of a long-term thermal processing partnership

Every successful business has that one customer.

The one whose challenges seem to fit the solutions you offer perfectly. The one who keeps coming back because with you, they can’t lose.

That’s the case with the customer in this case study, a major automotive supplier with facilities across North America.

What began as a single build for a single manufacturing line created additional opportunities to provide quality automotive thermal processing solutions that saved a lot of time and money.

Faster cycles & no part changeover delays

It started in 2006 when our customer won a huge job—production of components for one of the world’s all-time best-selling economy cars.

Among the high-volume parts they were assigned to manufacture were interior carpets for the model’s coupe and sedan body types. Manufacturing enough of these vehicle sets to meet OEM demand meant they would need to process a set every 30 seconds.

The OEM left it up to our customer to figure out how to make this happen.

At the time, almost all automotive textile manufacturers processed the individual layers of a carpet set separately. One oven would pre-heat the actual carpet layer (the finished surface we see in a vehicle interior). A second oven would pre-heat a cotton fiber sound dampening layer that rests below the carpet. After separate pre-heating, the layers would be placed one atop the other and then pressed into shape by a mold.

To successfully deliver the required volume of parts, our customer determined that they would need to process both coupe- and sedan-sized parts on the same production line in any sequence of size or color, every 30 seconds.

The ability to process parts according to a sequence was critical. This customer utilized In Line Vehicle Sequencing (ILVS), a system in which a supply chain produces parts in the sequence in which those parts will eventually be assembled in the OEM factory. These sequences are updated constantly—in some cases, every few hours.

Davron was brought in to help determine how a vehicle carpet production line could meet the customer’s production requirements and receive and interpret ILVS requests from the OEM factory.

We knew that switching parts or changing operational sequences from coupe to sedan was not an option because it would have caused significant delays. We proposed a system that required no changes during operation and featured a complex pick-and-place system that would load the correct size and color of material according to updated ILVS information.

We started by doing extensive product testing in our facility to help determine the ideal heating method for the individual products. Based on this data and the stated cycle time requirements, we developed a configuration for the overall system to operate at the proper cycle time in an automatic mode to meet any sequence requirements.

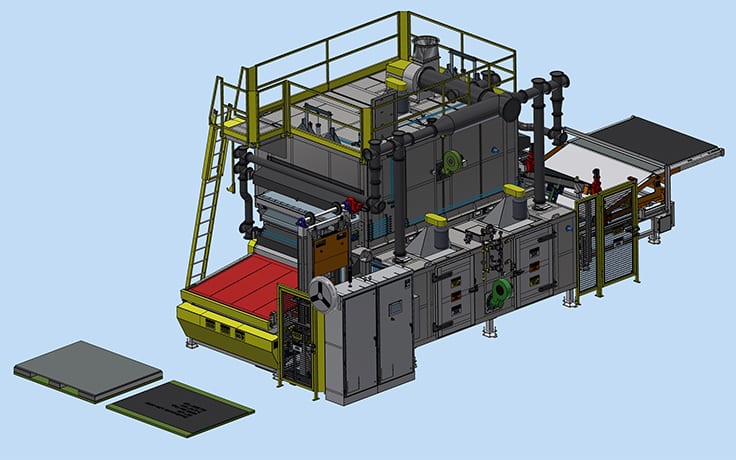

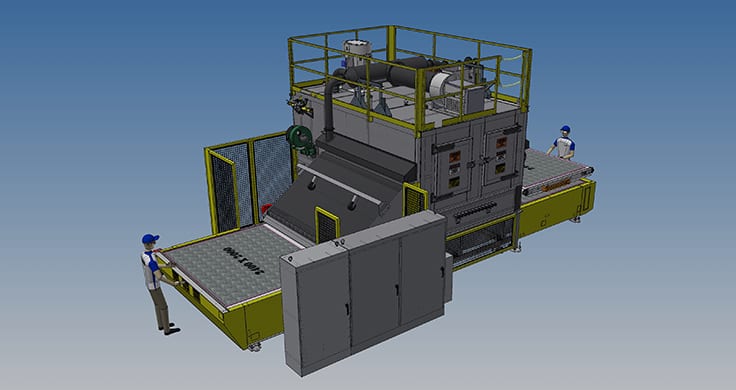

We then built the system—a three-zone forced-air convection oven stacked atop a two-zone infrared oven. The top oven pre-heated the cotton backing layer. The bottom pre-heated the carpet layer.

Our convection heating design included an air distribution system that provided the ability to heat either coupe or sedan blanks without the requirement to change any parts or operational settings. Operators needed only to press a button.

After pre-heating, both layers indexed out of their respective ovens with the backing layer laid precisely atop the carpet layer. The joined layers then proceeded to molding.

To say that the machine ran well is an understatement. It operated around the clock, often more than five days a week, for 12 years. Material changes for the products required new equipment for processing, but over its lifetime this system produced millions of vehicle sets.

A long-term partnership emerges

The first machine we built for this customer ran for over a decade, but it didn’t take near that long for them to realize the potential of a partnership with Davron.

The ability of that machine to process differently sized vehicle sets without an equipment changeover was a game-changer. The benefits were clear right away:

- No changeover downtime immediately eliminated the cost of not running and accelerated ROI

- The customer would not have to pay operators during downtime for part changes

- The maintenance burden for this unit was lower

- Production schedules became much more flexible

And that was just one machine on one manufacturing line. The customer knew they could multiply these effects if they adopted similar systems across their facilities.

Over time, that’s exactly what they did.

Today, multiple customer facilities across North America feature Davron production lines, each one meeting unique requirements that allow the customer to provide quality products to the OEM.

Back to the basics: quality equipment and great service

This partnership wasn’t built on quality machinery alone. It had just as much to do with the relationship that quickly formed between our team and theirs.

Our customer realized that Davron’s engineers understood manufacturing challenges and had a knack for solving problems with custom-designed equipment built to last.

And we knew that the opportunity to build for this customer would extend far beyond that first manufacturing line provided we kept listening, kept innovating and kept in touch.

So while the engineering required to solve automotive textile thermal processing challenges is quite complex, the key to keeping customers happy has always been simple.

Build quality equipment that does what customers need it to do. And when they call for help, pick up the phone.

Are you looking for fresh eyes to help solve production challenges in your facilities? Davron might be the ideal long-term equipment provider for you. Let’s talk more.