Concerns over capital equipment ROI are universal to anyone buying industrial ovens.

For all the potential operational benefits or quality improvements new equipment might represent, the price tag remains a determining factor. Machinery must be economical to own.

In other words, the bottom line is the bottom line, and it’s why some industrial oven providers prioritize cost savings over performance and longevity. It’s the commodity mindset to building industrial ovens: Make them cheap, make a lot of them and get them out the door.

But do buyers actually win when providers race to the bottom on price? After all, the number on the sticker never tells the full story.

Others — ourselves included — see a different situation. While it’s true that custom designs, quality materials and heavy-duty construction contribute to a higher cost to buy, over time this lowers total cost of ownership.

It’s the craftsmanship mindset that ultimately leads to better ROI.

Keep reading to see what we mean.

How design and material differences impact oven ROI

The way an industrial oven is designed, and the materials specified to build it, together impact its overall cost to own. And overall cost to own — NOT sticker price — is the right number to use when calculating ROI.

That’s because it accounts for all of the costs incurred to procure and operate a machine, not just what it took to get it into your facility.

But even that is not the full picture. Design and material decisions can lead to operational and safety concerns that cannot always be measured in dollars.

We share five such considerations below:

Replacement parts – Building with lower-priced or lower-quality parts introduces the risk that you’ll be replacing more parts more often over time. Behind those expenses lurk hours of unplanned downtime and increased labor costs associated with more frequent maintenance and repair.

Our approach: We want the machine to run well for a long, long time, so we use better-quality materials and components. The longer service life and reduced maintenance requirements more than justify a higher initial cost.

Insulation – Mineral wool is standard insulation for industrial ovens, but it comes in varying densities. Less dense is less expensive, but it’s also less effective. Low-density insulation diminishes temperature stability and forces heating elements to work overtime in compensation.

In addition, poorly insulated ovens can be hot to the touch — sometimes dangerously so. If they’re too hot, accidental contact could cause serious injury.

Our approach: Everyone wants and deserves a safe work environment. Among the principles guiding the design of our custom ovens is specifying denser insulation. It comes at a higher initial cost, but it’s offset by achieving better process temperature stability and tighter temperature tolerances, each of which are critical in complex thermal processes requiring extreme precision. As a bonus, it also results in an exterior surface that’s always cool to the touch.

Longevity – Low-cost industrial ovens are usually made of prefabricated sheet metal panels designed for tongue-and-groove assembly fastened by self-drilling screws. We’ve seen sheet metal as thin as 22 gauge. And, inside the oven, lower-quality heat generation and delivery systems contribute to lower heating efficiency, overall energy loss and frequent costly repairs.

Our approach: Davron ovens are made of thicker 16 gauge sheet metal welded to steel framework. They won’t fall apart. Ever. In addition to making our machinery sturdier, welded assembly of custom ovens contributes to a much better seal for improved thermal efficiency. Customers also have noted how easy our equipment is to move compared to more modular units that must be taken apart and put back together piece by piece.

And, higher quality heat delivery translates to more hours in productive service as well as less downtime and expense.

Product quality – Keeping in mind the three considerations above, it’s clear that the commodity mindset for oven design and material specifications creates the risk for reduced or inconsistent product quality. Can you afford high scrap rates? How many calls from unhappy customers are you willing to take?

Our approach: Davron engineers develop custom ovens for customers’ specific processes. Often, these customers supply highly complex parts to the aerospace, automotive and medical industries. To serve these customers well requires an intimate understanding of the product quality requirements they must meet, and an ability to reflect that understanding in industrial oven design.

Worker satisfaction – Show us an operator who isn’t annoyed by equipment that keeps breaking down and we’ll show you a unicorn. Show us a maintenance team that doesn’t get sick of fixing the same machine over and over again and…you get the idea.

Happy, engaged operators stay in their jobs longer. Low-quality equipment that keeps breaking down stands in the way of your workforce meeting its full potential.

Our approach: It’s simple. Industrial ovens ought to be well-built and straightforward to use and maintain. When they are, they’re here to stay. Your best operators will be, too.

Low-cost ovens have their place

We’re obviously biased. We only build custom-designed heavy-duty industrial ovens with the highest quality parts. Those cost more.

But paying the lowest price is not automatically the wrong decision. In some circumstances, simply buying a box that gets hot for a while is the most rational decision a company can make.

Generally, those circumstances include:

- Applications featuring only intermittent (as opposed to constant) thermal processing

- Smaller-scale manufacturing of comparatively low volumes of parts

- Processing parts where wider temperature fluctuations or less temperature uniformity can be tolerated

If you’re unsure whether a lower-cost or higher-quality industrial oven is best for your process, give us a quick call and we’ll shoot you straight. A Davron oven might be ideal. Or, it might be overkill. Either way, we’ll say so.

Think deeper & wider for accurate oven ROI

Purchasing decisions can only be as good as the information you have to go on. Basing yours on a simple comparison of sticker prices is like taking a nighttime hike without a flashlight.

So as you assess what kind of oven is best for your process, ask these questions:

- How do the operating costs of a low-cost option and a higher-quality option compare?

- What about maintenance requirements and frequency of part replacement?

- What ratio of uptime to downtime can I expect for each option?

- How much natural gas or electric heat energy does one require compared to the other?

- How long can I expect the machine’s components like heating elements or fans to perform?

- How well does each maintain a set temperature? And how precisely can I control temperature changes? Does such precise control matter to my application?

- Will the oven I choose be safe to be around? If someone touches it, will they get hurt? How much extra money will I need to spend on protective measures?

To get a feel for an industrial oven’s potential ROI, buyers must think deeper and wider. And as they do, the argument for investing in a high-quality oven built to last gets more and more compelling.

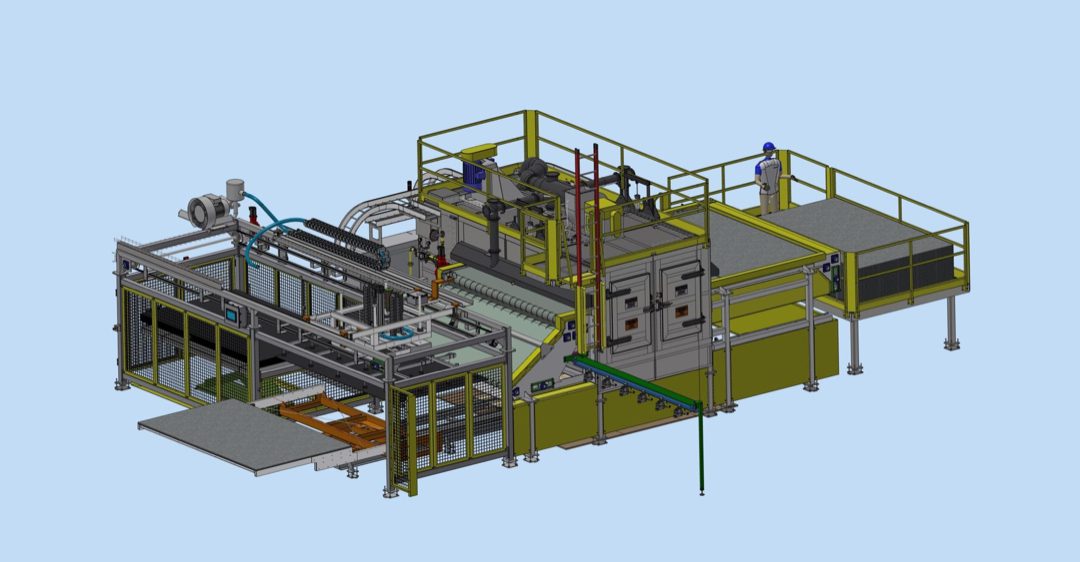

Use this specifying guide to aid in your research. It focuses specifically on conveyor-type ovens, but its content can apply more widely and might be helpful to you. Browse our custom oven overview, too. You can sort by material, application, oven type or industry to see if a Davron oven is right for you.

If you’d rather just talk to someone about it, contact us here. We’ll get you in touch with an engineer.