Case study: Atypical foam crosslinking oven specs lead to design innovation

Industrial foam manufacturing is tricky.

The equipment used to create bulk foam products varies widely depending on what kind of foam is being made and into which application (and there are countless thousands of them) it’s being sold.

To that end, there are two kinds of foam manufacturers—those who know exactly what kind of production equipment they need, and those who rely on equipment suppliers to help develop manufacturing processes during equipment design.

This customer, however, was a little bit of both. Our engineers walked the balance beam, playing equal parts responsive vendor and value-adding collaborator.

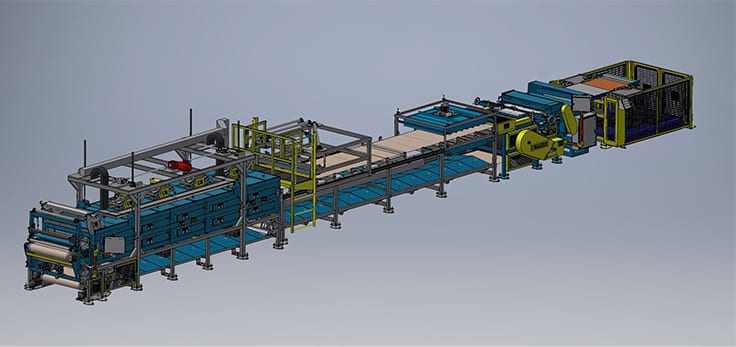

They stuck the landing with this system.

Next-generation foam manufacturing

Our customer was a global manufacturer of foam products serving seemingly every sector you can think of that has foam applications. As part of their systematic global production capacity increase in 2016, a plant in the United States was due for new equipment.

Specifically, the company wanted to purchase ovens that crosslinked plastic slabs following extrusion onto a conveyor and preceding the rest of the foaming process.

Foam can be made in many ways, and this customer had developed a one-of-a-kind manufacturing process. And while their first-generation equipment was serving them well, they elected to develop a second generation for this facility to improve on the design and execute their unique process even better.

During a web search for ‘crosslinked polyethylene foam systems’ they came across the industrial foam ovens and post-processing equipment we’ve built for manufacturers across the globe. Sensing a good fit, they sent us the specs.

It was obvious the customer had done their homework. They knew exactly what they needed. The oven they specified was unusual for its small size. Most crosslinking ovens are spacious enough for people to walk around inside. (Like this triple-decker oven, for instance.)

But this customer specified much smaller dimensions. And even though they were quite prescriptive in their specs, the uniqueness of the project served up the opportunity for our engineers to propose and develop the novel design innovations described below.

Lift system improves ease of access

The small size of our customer’s specified oven meant that maintenance personnel would have restricted access to its internal components. To address this, similar ovens in our customer’s flagship plant were designed with hinges on one side that allowed them to open.

The customer wanted something similar for the new systems, but our engineers believed they could improve on the design. Instead of recreating Pac-Man, we proposed an external frame with a machine screw jack system to lift the entire top half of the oven. This allowed for 360-degree maintenance access.

The customer endorsed this design update knowing it would provide even easier access for maintenance or repairs of the rollers, bearings and other components that would make up the machine’s conveyor.

Custom alternative to direct-drive fans

The customer’s original specification called for direct-drive circulation fans. These are simple in design—just a fan wheel attached directly to an electric motor shaft extending down into the heating chamber.

But this design introduces a failure risk by exposing the fan’s electric components to too much direct heat when operated continuously. We proposed a more traditional belt-driven fan design to protect the motor from exposure to excessive heat.

The customer agreed to this modification, too. But because our normal fan manufacturer couldn’t build this to our customer’s unique dimensional constraints, our engineers designed and built it themselves.

Solutions-based partnership

As we said above, foam manufacturing is tricky. There are potentially as many ways to make it as there are end uses for it.

This case study demonstrates one of the key differentiators of working with Davron. We provide solutions, not merely industrial heating equipment. And sometimes—as in this case—that means straddling the line between delivering exactly what the customer said they needed and proposing design innovations that improve upon established manufacturing processes.

If that’s the kind of partnership you envision for your next project, we’d like to talk about it with you.