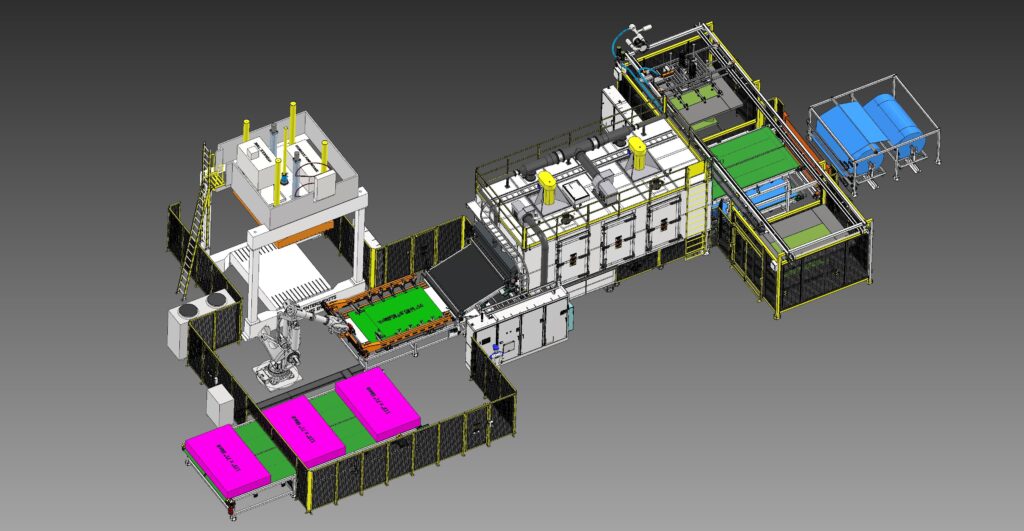

A full production line from a single manufacturer

Davron Technologies builds custom thermal processing equipment. We also design, build, assemble and integrate upstream and downstream equipment, up to a complete production line.

Get A Quote (New w/ file upload)

"*" indicates required fields

One purchase order for an integrated production line

A press from one supplier, plus a conveyor from another, plus an oven from another… It adds up to an overcomplicated expansion and a mess of an integration project.

We design, build, integrate and support complete production lines. All you need is raw material, and we deliver a line capable of producing any volume of finished parts.

High-performance equipment built to your process

Installation and integration in weeks, not months

It shouldn’t take months to integrate automated equipment on new production lines. Especially when delays can cost manufacturers as much as the equipment itself.

We speed up the process by assembling and integrating your production line in our facility. When it’s ready, you test it in our shop. Then we’ll ship the whole line in modules, so you won’t need more than three weeks for start-up.

One reliable source for support and service

Do yourself — and your maintenance team — a favor. And install a complete production line with Davron.

You’ll only need to remember one phone number because piece of equipment is designed, manufactured and assembled in-house. Want to update programming? Call us. In need of a spare part? Also us.

See how it worked for an automotive carpet manufacturer

An automotive carpet manufacturer had a problem: Their finished parts weren’t adhering properly due to thermal pre-processing challenges. We’d seen this problem before and knew how to solve it.

We proposed a method they hadn’t considered, proved out the concept before kicking off the project, then built a complete production line. The line turns blanks into one finished part every minute or so, ad infinitum.

Hear from our happy customers

“They could do anything we wanted them to do. Their versatility was what really won our business in my opinion.”

“We don’t buy standard, off-the-shelf equipment. When we buy what we buy from Davron, we get a solution that helps us produce what we want to produce.”

Let’s start working together

Expect a response within a couple days. We’ll get to know you, your application and what you need from a production line.