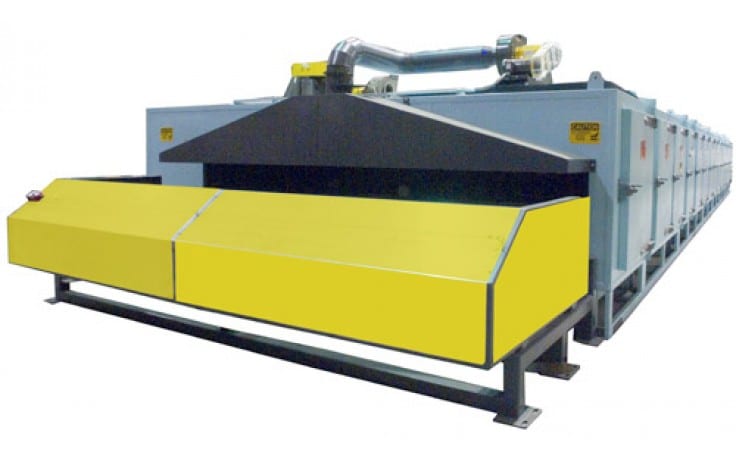

DTI-954 Indexing Conveyor Oven

Description

The DTI-954 multiple zone indexing conveyor oven heat treats automotive coil springs used for suspension systems. The coiled springs are placed in custom trays included with the conveyor oven system, and are conveyed through the oven for tempering. The tray system processes six parts per row and the conveyor oven system indexes based on timed increments through the length of the oven. Multiple heat zones are included to allow temperature variations used to create temperature profiles. The process requirement dictates that parts are heated at a controlled rate up to the maximum temperature. Temperature is reduced at a controlled rate prior to exit from the system.

Specifications

| Chamber External Dimensions | 67′-8″ L x 19′-7″ W x 5′-4″ H (20625mm x 5969mm x 1626mm) |

| Conveyor Usable Size | 66′-4″ L x 15′-3″ W x 1′-5″ H (20218mm x 4648mm x 432mm) |

| Insulation Thickness | 8″ (203mm) |

| Conveyor Extensions | 5′-6″ (1676mm) on both Entrance and Exit End |

| Conveyor Type | Custom Design Product Trays |

| Conveyor Control | PLC controlled index based on time |

| Heat Source | Four Modulating Natural Gas Fired Burners |

| Design Operating Temperature | 300°F – 800°F (149°C – 427°C) |

| Maximum Operating Temperature | 800°F (427°C) |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Control | PLC control for all functions with operator touch screen (HMI) |

| Conveyor Tension | Constant Pneumatic take-up to compensate for thermal expansion |

Alternative capabilities

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous

Features

Automotive supplier advantages

- Provides in line manufacturing

- Reduces labor force of batch process in regards to handling required to load and unload product into racks

- Eliminates multiple batch ovens required to keep pace with production

Automotive oven features

- The oven is gas heated

- Multiple zones for custom temperature profile

- Constant pneumatic take-up compensates for conveyor thermal expansion during operation

- The conveyor system indexes on timed increments as required for the production rate

- All functions of the machine are controlled by PLC with an operator touch screen (HMI)