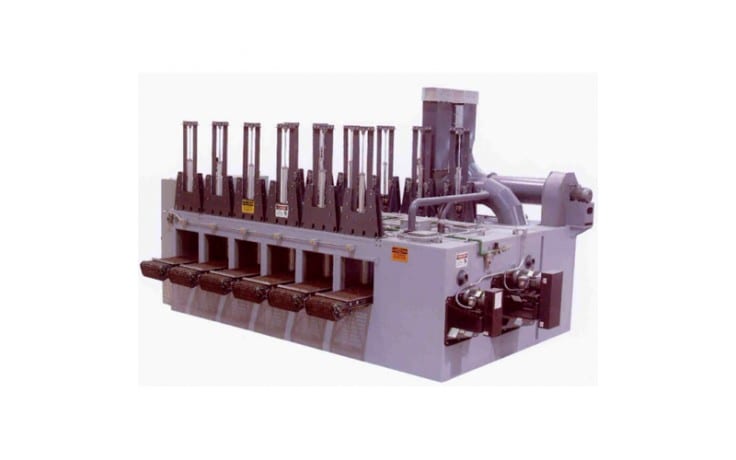

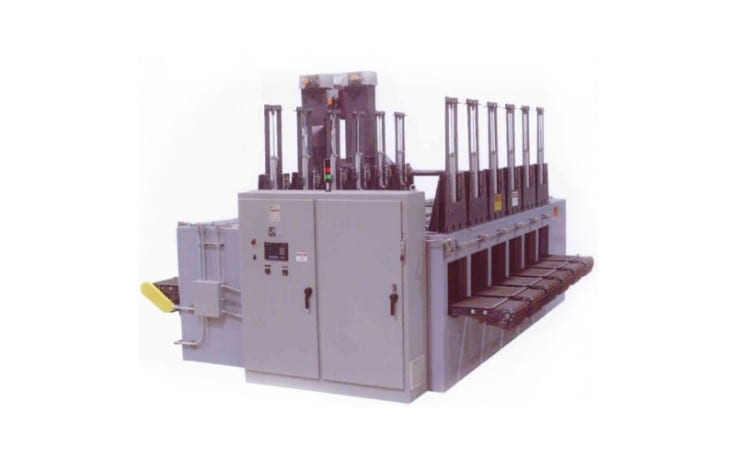

DTI-645 Curing Conveyor Oven

Description

The DTI-645 conveyor oven thermally cures silicone parts in cast aluminum molds. This system includes six independent conveyors passing through the heated chamber. The independent conveyors provide the ability to process parts at different rates in the same conveyor oven based on the drying time requirements. Airflow within the conveyor oven is a combination of vertical up and vertical down to the product on the conveyors.

Specifications

| Chamber External Dimensions | 11′-3″ L x 17′-8″ W x 5′-6″ H (3429mm x 5385mm x 1676mm) |

| Conveyor Usable Size (each) | 10′-9″ L x 1′-6″ W x 1′-6″ H (3277mm x 457mm x 457mm) |

| Insulation Thickness | 4″ (102mm) |

| Conveyor Extensions | 2′-2″ (660mm) Entrance End and Exit End |

| Conveyor Type | Flat Wire |

| Conveyor Control | PLC Controlled Index |

| Heat Source | Two SCR Controlled Electric Heaters |

| Design Operating Temperature | 200°F – 400°F (93°C – 204°C) |

| Maximum Operating Temperature | 400°F (204°C) |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Control | PLC with Operator Touch Screen for all functions |

Alternative capabilities

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous

Features

Conveyor oven construction features

Conveyor index is independently based on time through a single position ramp zone, a three position soak zone, and a two position cooling zone within the process. The conveyors extend beyond the chamber on each end for loading and unloading. The heated chamber includes vertical doors at each end of the heated chamber which open and close during each index to minimize heat loss during the cure cycle.