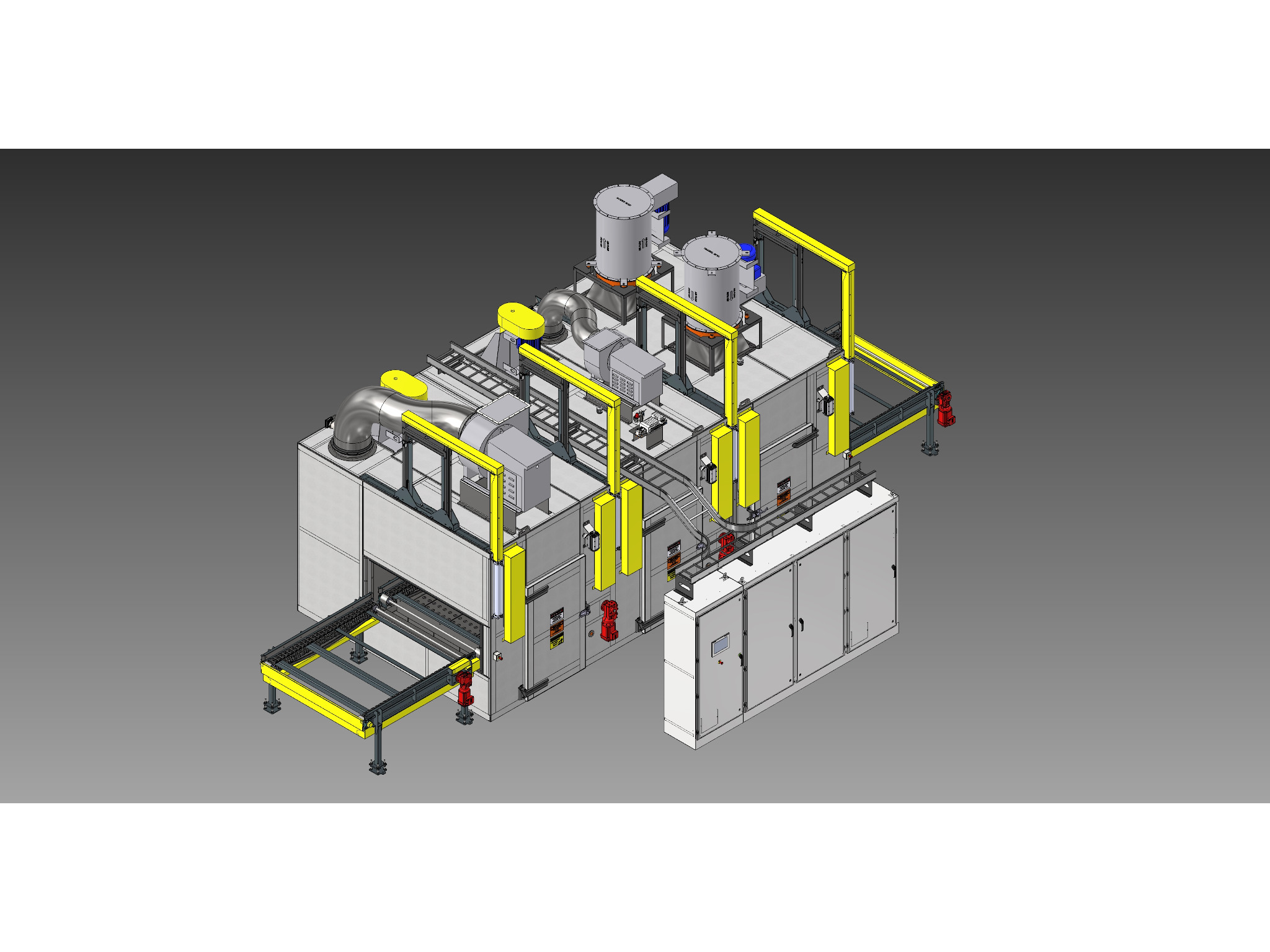

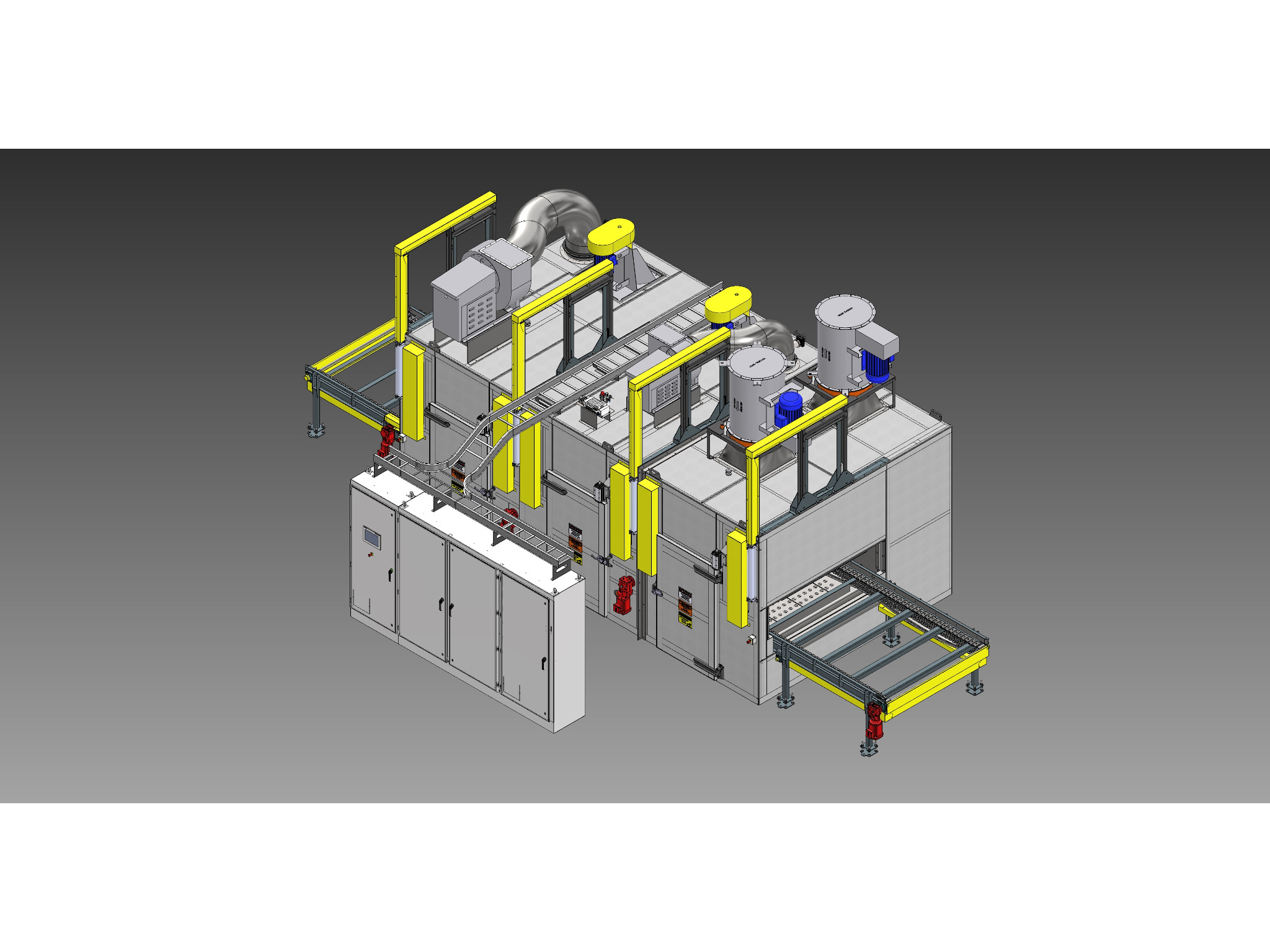

DTI-1539 Drying Conveyor Oven(s)

Customer directive

The customer was processing a saturated block of fiberglass that required approximately 200 lbs of water to be removed. One of the challenges of this process was ensuring that the entirety of the fiberglass block was dried, not only the surface. In order to accomplish this process, a automated blank off system was developed to direct airflow up through the product. In addition to the drying process, product needed to be cooled prior to moving to downstream processes.

Description

The DTI-1539 conveyor oven system features (3) independently controlled zones: (1) electrically heated and (1) ambient cooling. Product is placed onto the customer’s pallet that is then loaded via overhead crane onto the equipment’s indexing conveyor system. Each zone is separated by a vertical door to ensure temperature and airflow uniformity. Sensors stop the pallet accurately so that the mechanical blank off system can seal to the product and direct air through it. The customers part varies in length and width which requires the blank off mechanism to accommodate different sizes. The blank off mechanism utilizes a swinging element and a translating element to accommodate the range of sizes while still sealing to each other.

Specifications

| Product Being Processed | Corrugated Fiberglass Blocks |

| Overall System Dimensions | 36′-8″ L x 14′-2″ W x 14′-5″ H |

| Interior Chamber Dimensions | 18′-9″ L x 6′-0″ W x 1′-9″ H |

| Type of Heating System | Electric |

| Design Operating Temperature | 200°F – 350°F (93°C – 177°C) |

| Maximum Operating Temperature | 400°F (204°C) |

| Product Support | Oversize roller conveyor chain with custom attachments. |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Vertical top-down, could be from any direction depending on process requirements

- Industries Served: HVAC, aerospace

- Materials Processed: Fiberglass, corrugated products, honeycomb or cellular type products

- Other Processes: Preheating, curing, drying, solvent drying, bonding

- Heating Systems: Electric, modulating gas fired, direct or indirect, thermal oil