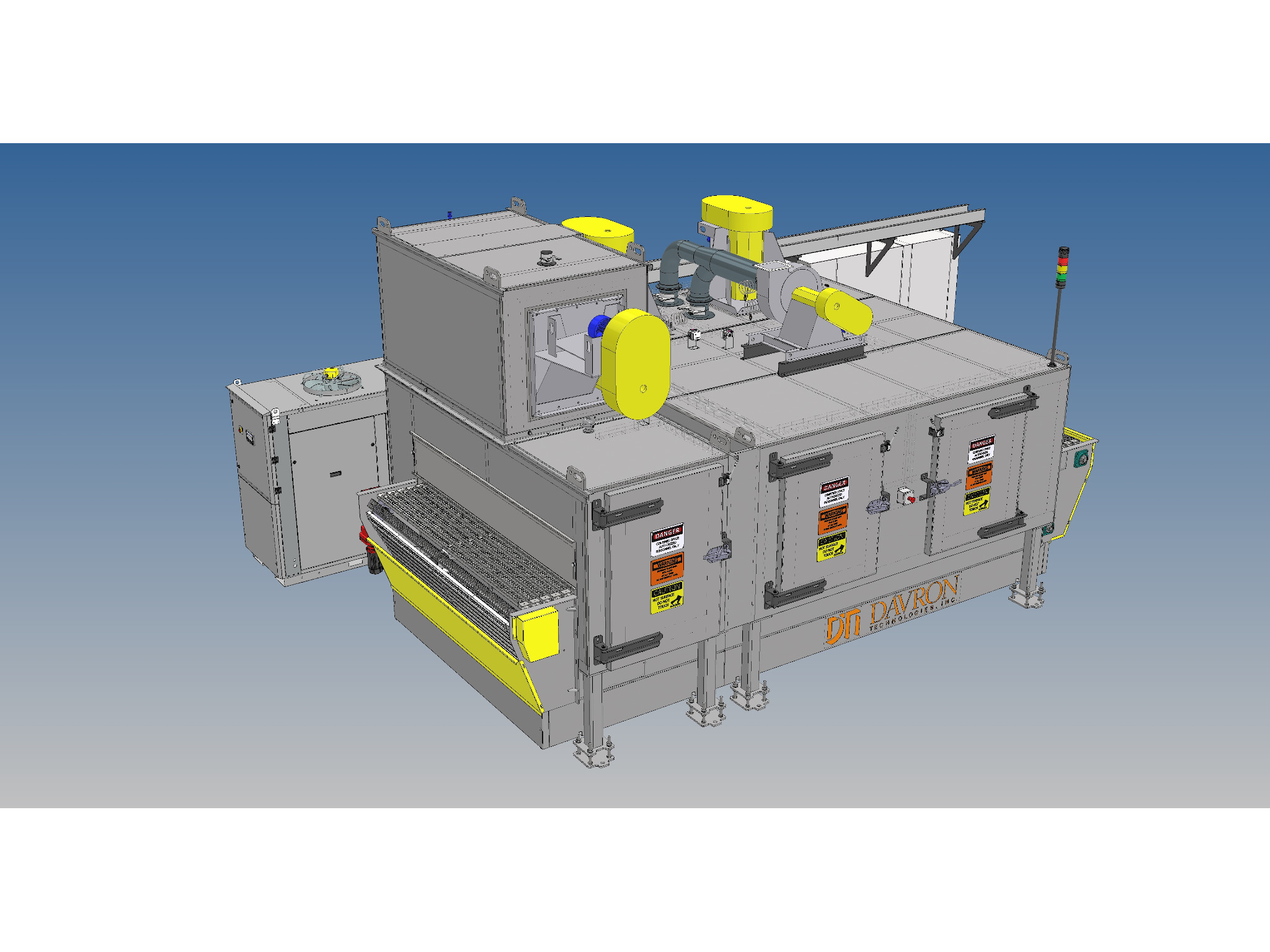

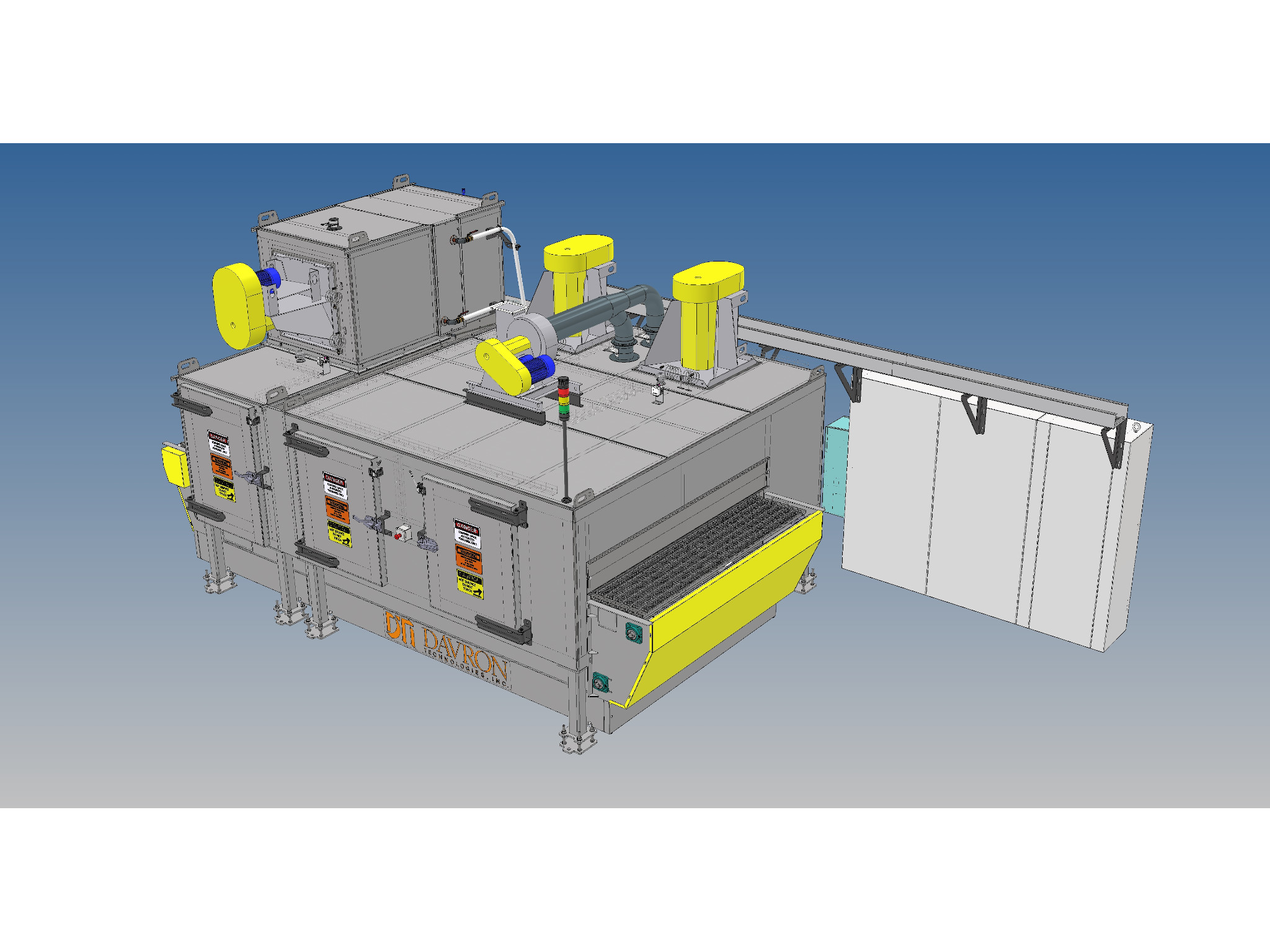

DTI-1511 Conveyor Oven & Cooler

Customer directive

Davron’s customer was looking for an oven solutions provider that could work with them in the development of a new, highly automated, manufacturing line to produce multi-pin automotive electrical connectors. During the process, the silver and tin electrical connecting pin bases are set in an epoxy resin that must be cured before proceeding to the next stage. This manufacturer needed an oven they could easily integrate with their own load/unload automation, existing controls standards, and available footprint. The parts needed to be heated to a minimum cure temperature as quickly as possible, held for a minimum amount of time, then cooled to be able to continue on the manufacturing journey.

Description

Davron was able to offer the flexibility and optimization to meet this customer’s performance and packaging requirements. Davron performed in-house testing on the products to determine appropriate heat up and cool down times, which they optimized with the client to minimize oven length, reduce product rejects due to overheating, and accommodate their automation. Custom stainless trays were developed that allowed automation flexibility without any risk of damage to the parts. A chiller was incorporated into the cooling section to accommodate varying part loads and conveyor index speeds, while still meeting the required part temperature specifications.

Specifications

| Product Being Processed | Automotive electrical connectors, epoxy resin curing |

| Overall System Dimensions | 24′-1″ L x 14′-6″ W x 10′-2″ H |

| Heated Chamber Dimensions | 9′-0″ L x 7′-4″ W x 1′-1″ H |

| Type of Heating System | Electric |

| Design Operating Temperature | 257°F (125°C) |

| Maximum Operating Temperature | 279°F (137°C) |

| Product Support | Stainless conveyor trays |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Top and Bottom, Horizontal cross-flow, Bottom Up

- Industries Served: Automotive, Electronics, Aerospace, Composites, General Manufacturing

- Materials Processed: Plastic, Epoxy, Resin

- Other Processes: Batch, continuous

- Heating Systems: Natural gas, propane