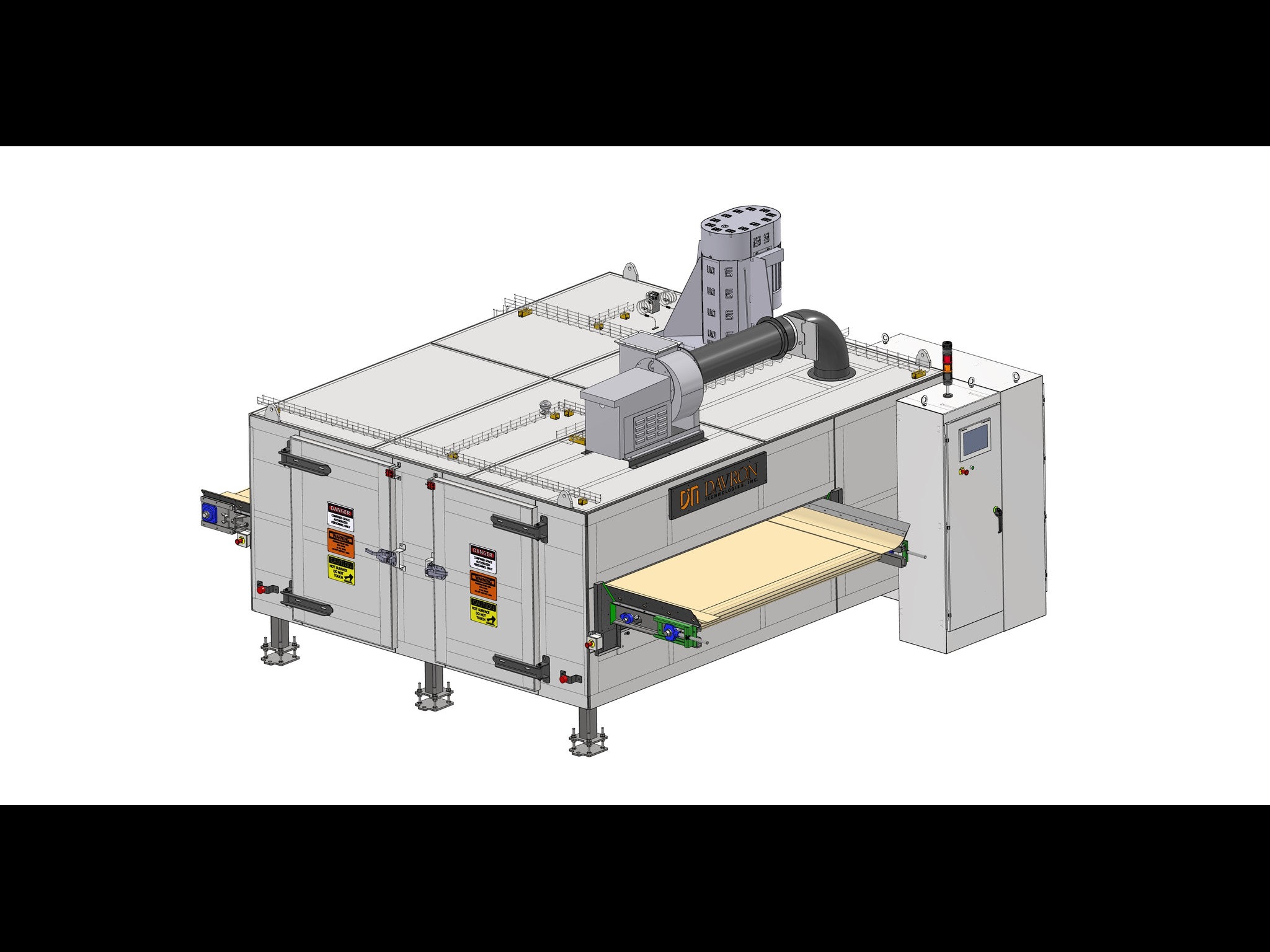

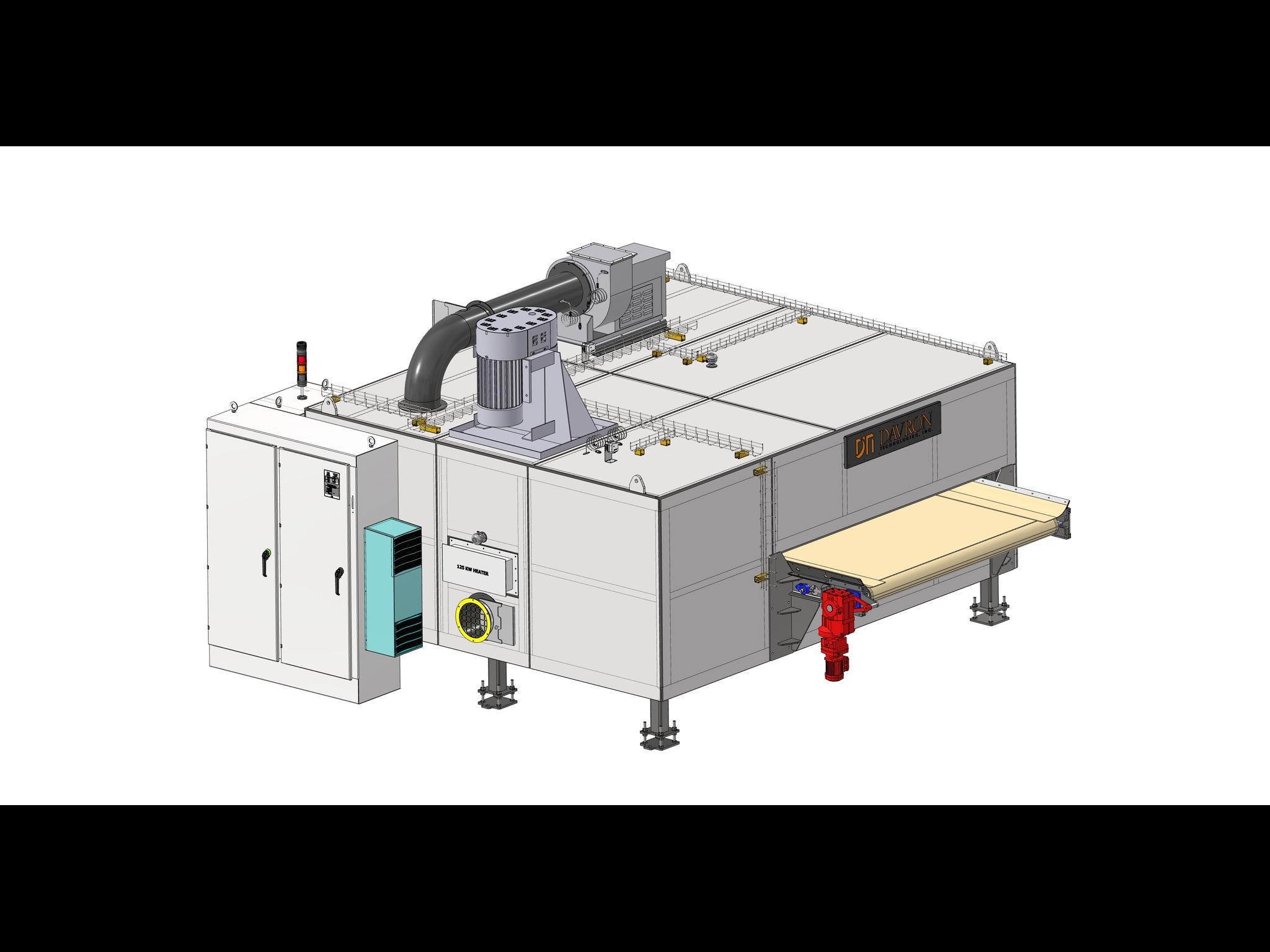

DTI-1496 Conveyor Oven

Customer directive

Davron was directed by our customer to design and manufacture a continuous conveyor oven to remove excess moisture from their product, which is the nut of a Tung tree. The oven needed to have very accurate control of temperature, air flow, and material movement in order to properly dry and not misplace the product during process.

Description

The customer supplied the product load conveyor which feeds the nuts onto the oven conveyor. The oven chamber is operated as a single zone of temperature control including a circulation fan, exhaust fan, electric heater, and two (2) conveyors. The conveyor system is divided into two sections with a 6” drop halfway through the chamber. This drop allows the product to turn over and evenly heat the opposite side. The product then leaves the oven and drops the Tung nuts onto a customer supplied take away conveyor to proceed through the manufacturing process.

Specifications

| Product Being Processed | Tung Nuts |

| Overall System Dimensions | 15′-6″ L x 14′-6″ W x 9′-4″ H |

| Heated Chamber Dimensions | 10′-0″ L x 11′-9″ W x 4′-3″ H |

| Type of Heating System | Electric |

| Design Operating Temperature | 100-300°F (38-149°C) |

| Maximum Operating Temperature | 400°F (205°C) |

| Product Support | Teflon conveyor belt |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Top and Bottom, Horizontal cross-flow, Bottom Up

- Industries Served: Automotive, Electronics, Aerospace, Composites, General Manufacturing, Food & Beverage, Industrial Foam, Medical

- Materials Processed: Any

- Other Processes: Batch, continuous

- Heating Systems: Natural gas burner, propane burner, electric duct heater, infrared/radiant heat