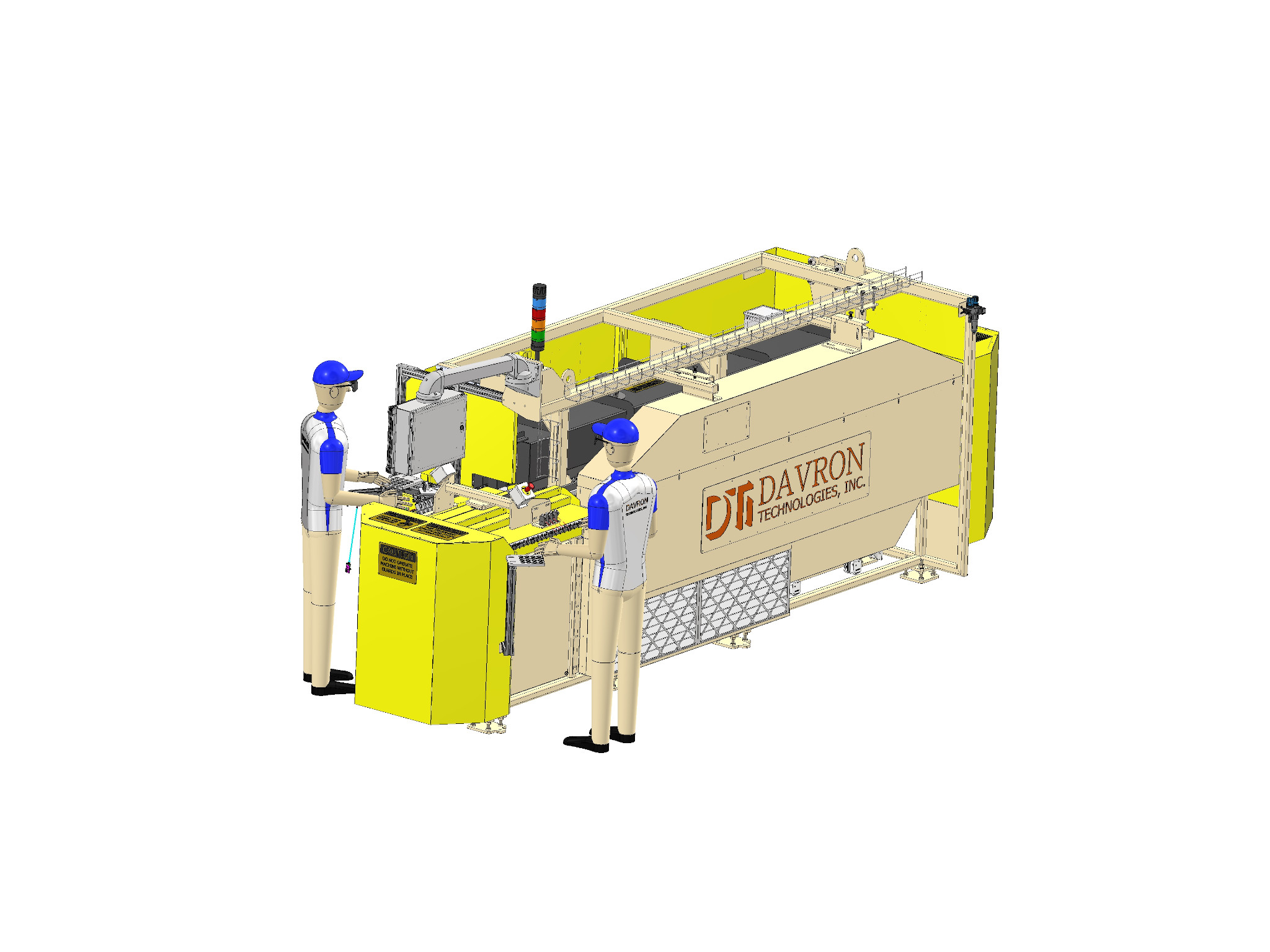

DTI-1491 Indexing Conveyor Oven

Customer directive

The customer required a precise heating process to be applied to a very small automotive sensor. The geometry and nature of the part dictated that various areas had to be above a certain temperature while immediately adjacent areas could not be over a lower temperature. The distance between heating temperatures is as little as 0.4” (10mm). This focused heating requirement posed a unique challenge. Parts are loaded and unloaded by hand, therefore after heating, parts also had to be cooled to a safe temperature to be handled by an operator. Each part presented to the oven has a unique barcode with process data from upstream operations. Data from the heat treating process had to be attached to each part for downstream operations.

Description

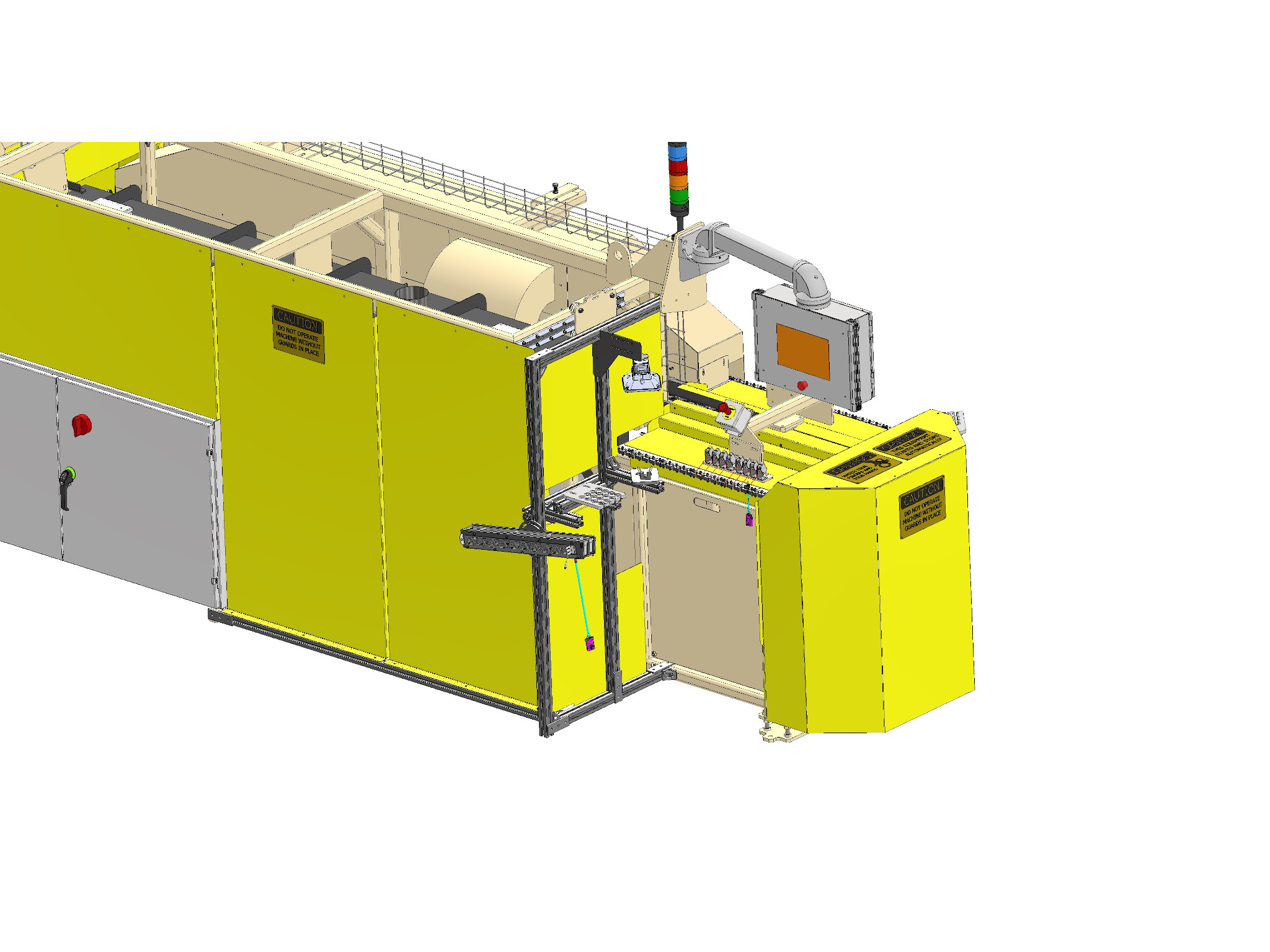

Davron designed a custom product tray that attached to the conveyor chain. Each tray held four (4) parts while shielding certain areas of the sensor from the heat source to ensure it did not exceed the customer’s temperature threshold. While the tray shielded certain areas of the sensor from excess temperatures, it also allowed the upper portion of the part to be properly heated in order to produce an acceptable part.

The oven chamber was designed with an open bottom so that the indexing conveyor trays exposed the top of the parts to the heater rods but the bottom of the parts were kept relatively cool by the trays and open air. The oven chamber consisted of two heated zones to produce a ramp and soak heating profile. After heating, parts were then conveyed through a forced cooling section utilizing a supply and exhaust fan blowing filtered air across the parts. DTI-1491 was equipped with a barcode scanner, two conveyor load positions, a reject chute, and a variety of sensors. Communication between the PLC and the customers network was established so that as each part is scanned prior to entering the heated chamber. The operator is guided to either place good parts on the product tray or bad parts in the reject chute. At the exit end, sensors detect unloaded parts and the PLC sends heat treating data to the plants traceability system for each part.

Specifications

| Product Being Processed | Automotive Sensors |

| Overall Equipment Dimensions | 15′-4″ L x 5′-6″ W x 7′-4″ H (4674mm x 1676mm x 2235mm) |

| Heated Chamber Dimensions | 8′-0″ L x 0′-5″ W x 0′-4″ H (2540mm x 127mm x 102mm) |

| Type of Heating System | Electric heater rods |

| Operating Temperature | 842°F (450°C) |

| Maximum Temperature | 1292°F (700°C) |

| Product Support | Custom designed conveyor trays |

| Controls | PLC control with operator HMI, UL listed control enclosure, product barcode scanner |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Natural convection

- Industries Served: Automotive, pharmaceutical, aerospace

- Materials Processed: Automotive parts, electrical sensors, metals, ceramics, glass

- Other Processes: Preheating, curing, drying, bonding, sintering, annealing

- Heating Systems: Electric heat, infrared, radiant