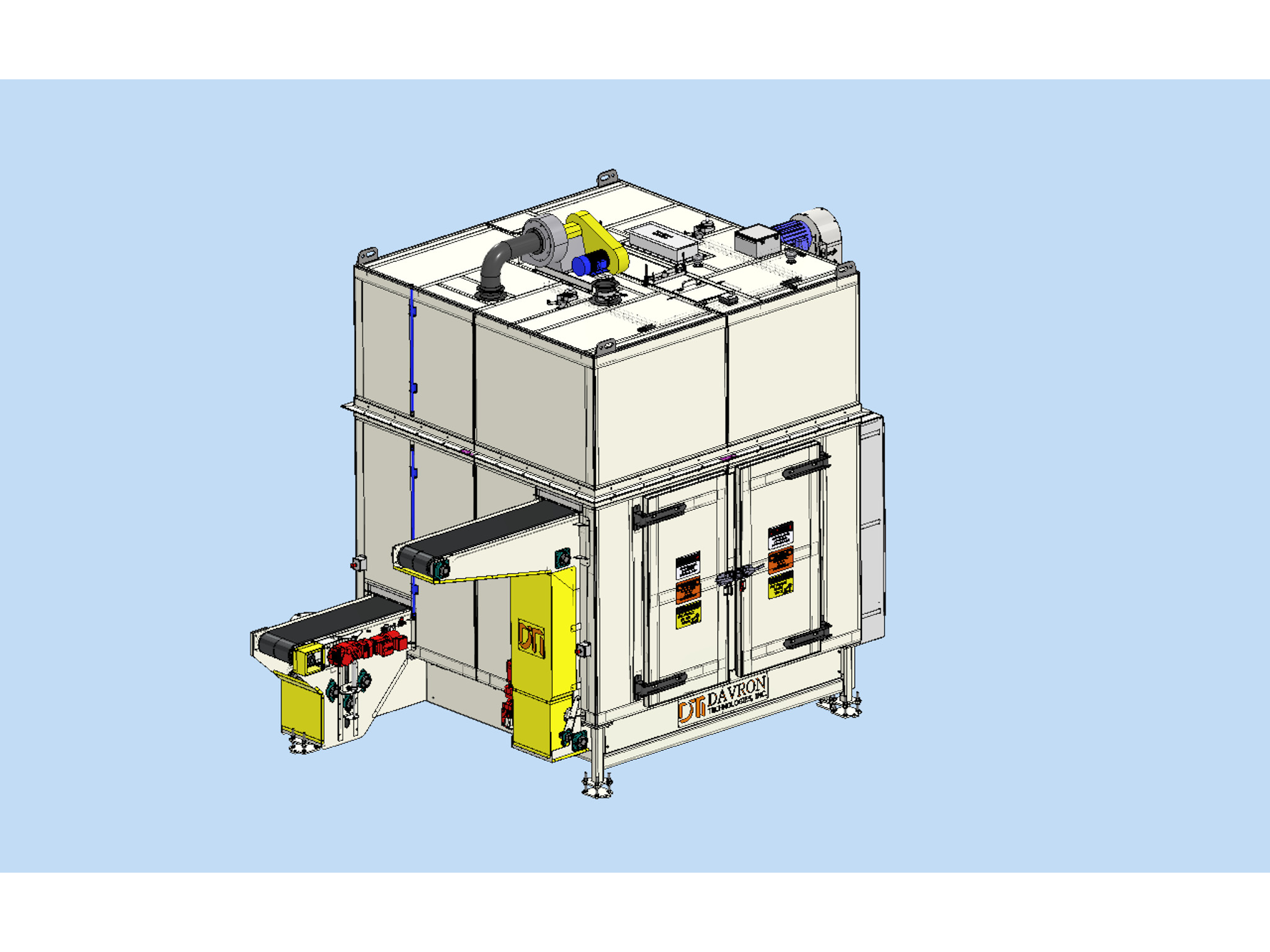

DTI-1481 Spiral Curing Oven

Customer directive

The customer had need of a continuous conveyor oven that could hold a high quantity of small parts, with a long cure time and take up a minimal footprint their facility. It was requested that Davron design a spiral oven to meet these needs. With the components being medical in nature and the oven being installed in a Class 1 clean room, extra care was taken to minimize any foreign object debris or dust that could accumulate on the product while in the oven. The oven is loaded and unloaded via automation.

Description

The spiral oven is a “Down Go” arrangement where the product is loaded approximately 8ft off the floor and exits approximately 3ft off the floor, entering and exiting on the same side of the oven. The conveyor belt rides on replaceable Teflon pads and is driven by a large center drum that the belt wraps around. The drum plays a simultaneous role as the return air plenum, pulling air from supply ducts located in the four corners of the product chamber and across the belt/product. The air is then filtered through replaceable high-temperature MERV14 filters to ensure any airborne contaminants are not returned to the supply plenums. A differential pressure monitor is installed to assist in measuring filter life. Stainless steel interior, conveyor supports, and contact surfaces ensure medical grade cleanliness.

Two vertically hinged doors on either side of the oven, along with a removable center door jam, provide interior access for cleaning and maintenance. Pneumatic belt tensioning provides consistent and adjustable belt tension, while variable frequency drives offer tunable control of the two conveyor belt drives, circulation fan and exhaust fan. An adjustable belt cleaning brush utilizes FDA-approved bristle material to clean the belt as it returns to the entrance.

Specifications

| Product Being Processed | Plastic/Silicone Composite Components |

| Overall Length, Width and Height | 17′-0″ L x 9′-8″ W x 13′-8″ H (5182mm x 2946mm x 4166mm) |

| Conveyor Width | 14″ (356mm) |

| Type of Heating System | Electric |

| Design Operating Temperature | 150-270°F (66-132°C) |

| Maximum Temperature | 300°F (149°C) |

| Product Support | Stainless steel conveyor bed, teflon belt supports |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Center out, Top down, Bottom up

- Industries Served: Medical, Pharmaceutical, Automotive, Aerospace, Food and Beverage

- Materials Processed: Ceramics, plastics, composites, Friction Materials, smaller individual components

- Other Processes: Drying, Baking, lower temperature applications (300°F or less)

- Heating Systems: Gas fired