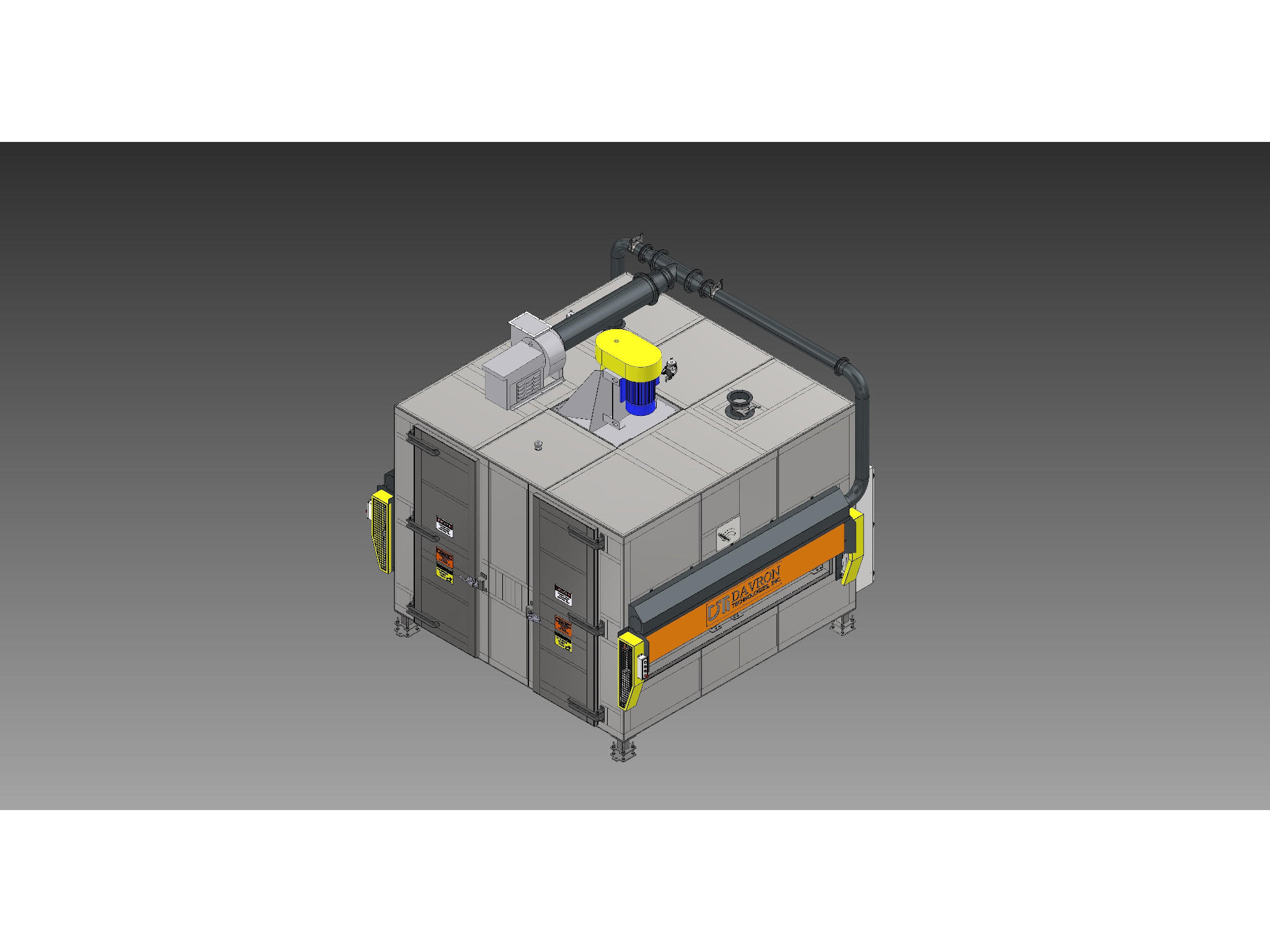

DTI-1474 Batch Oven

Customer directive

The customer wanted a means to preheat Bico Nonwoven materials utilizing forced convection from the top and/or bottom of the material.

Description

The material is supported by a tube frame that is manually loaded into the oven by the operator. The operator pushes the frame into the oven through pneumatic chamber door openings and onto the roller rails inside of the oven. A push button is used to open and close the chamber doors and another push button starts the cycle. Once the cycle has been initiated, the oven chamber doors automatically open once a set time has been reached.

The airflow and direction inside of the oven product chamber is fully adjustable by means of internal plenum dampers that can be manipulated by external adjustment handles. This allows the customer to change the airflow from the top of the product downward, from the bottom of the product upward, or both.

Specifications

| Product Being Processed | PE/PET Bico Nonwoven Material |

| Overall Dimensions | 14′-0″ L x 14′-0″ W x 13′-0″ H |

| Heated Chamber Dimensions | 10′-6″ L x 10′-0″ W x 2′-6″ H |

| Heating System | Gas Fired Burner |

| Design Operating Temperature | 350°F (177°C) |

| Maximum Operating Temperature | 450°F (232°C) |

| Product Support | Manually adjustable product rails with rollers |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Fully adjustable vertical or horizontal

- Industries Served: Aerospace, Automotive, General Manufacturing, Textiles

- Materials Processed: Nonwovens, Plastic Composites

- Other Processes: Pre-heat, Curing, Drying

- Heating Systems: Gas Fired