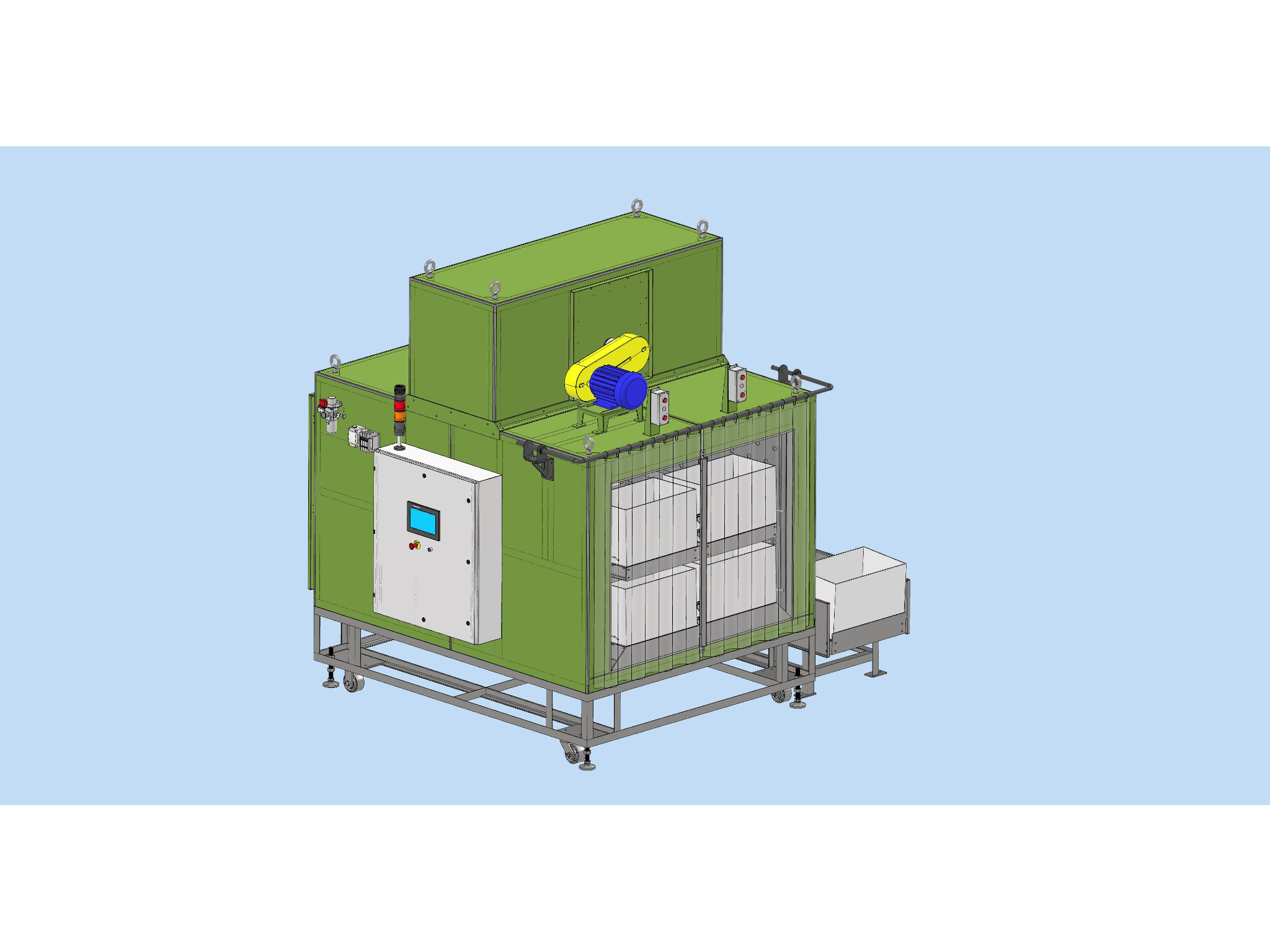

DTI-1469 Harness Warmer

Customer directive

Davron was directed to engineer and manufacture an oven system to heat the customer’s electrical harnesses up to temperature prior to moving through the assembly process. The customer required flexibility to move the equipment around the facility as needed and had floor space constraints that needed to be designed around. In order to meet production requirements, three (3) warming systems were completed.

Description

Product is manually placed in plastic totes and loaded onto a gravity roller conveyor that feeds the product into the heated chambers for process. Airflow within DTI-1469 is horizontal crossflow across the product. In order to reduce the overall length of the oven, the customer request there be four (4) rows of totes instead of a single row. Plastic curtains are included on the load and unload ends of the system to allow ease of access to the product for loading and unloading. The system includes an electric heater and circulation fan for uniform airflow within the chamber. Once product is properly heated, the operator will manually unload the parts and place the empty tote on the return chute to return to the load end of the system. The control system includes a PLC and HMI touch screen to operate all aspects of the equipment. The entire system is fully assembled and factory tested for operational verification prior to shipment.

Specifications

| Product Being Processed | Plastic wiring harnesses for the Automotive Industry |

| Overall System Dimensions | 8′-0″ L x 6′-6″ W x 9′-4″ H |

| Heated Chamber Dimensions | 7′-4″ L x 5′-2″ W x 4′-4″ H |

| Type of Heating System | Electric |

| Design Operating Temperature | 68°F – 104°F (20°C – 40°C) |

| Maximum Operating Temperature | 176°F (80°C) |

| Product Support | Gravity Roller Conveyors |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Designs can be completed to provide airflow from any direction within the heated chamber as required by the product. This particular process is horizontal crossflow.

- Industries Served: Automotive, Manufacturing/Regeneration, or any industry that requires conveyor processing.

- Materials Processed: Particularly any Automotive Wiring with a directional flow requirement. The oven /conveyor system can also be used for many other types of products and can be designed in any size required.

- Other Processes: Preheating, Curing, Drying, Solvent Drying, Bonding

- Heating Systems: Modulating Gas Fired Direct or Indirect, Electric, or Thermal Oil.