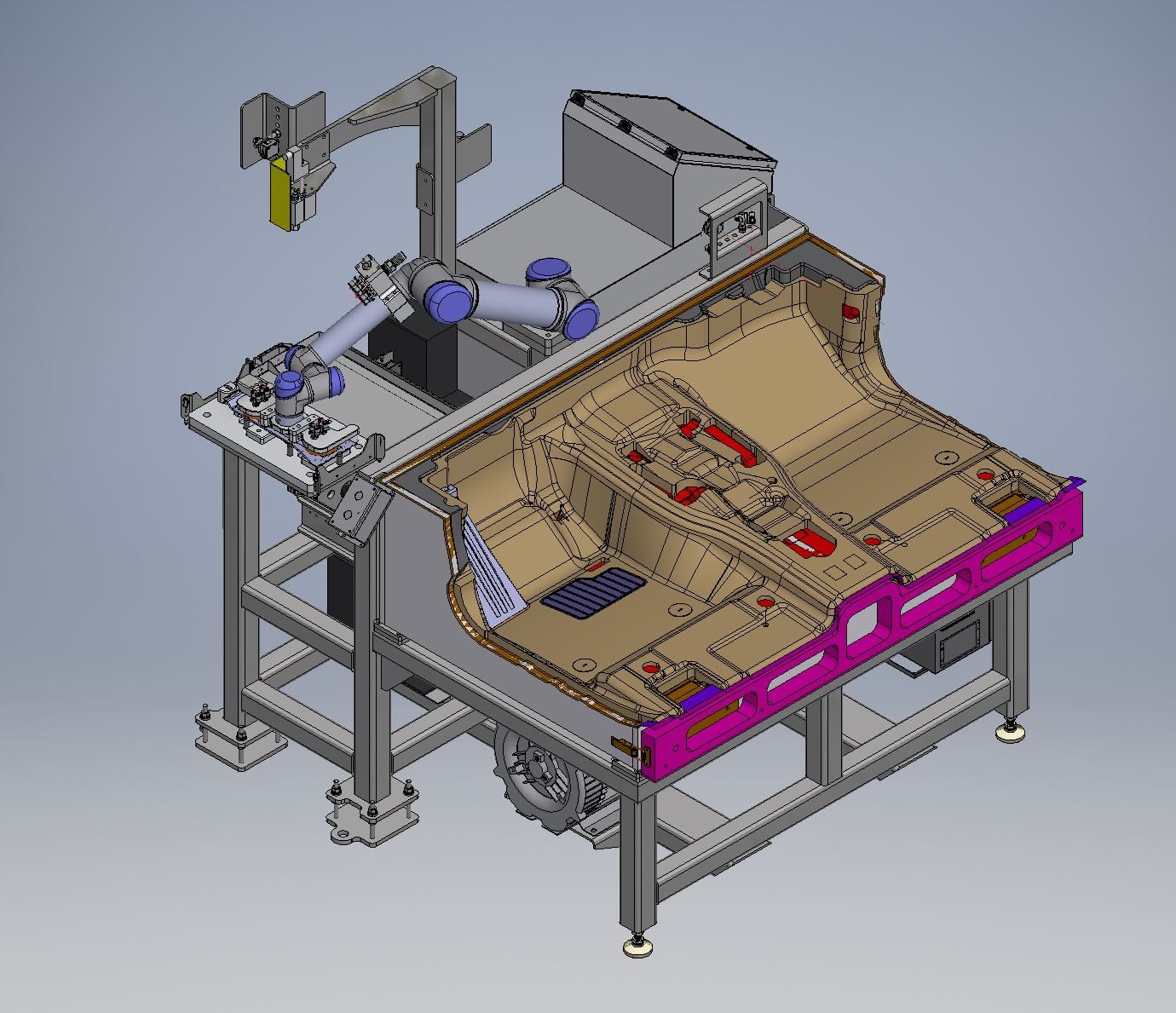

DTI-1330 Automated Assembly Machine

Customer directive

The customer was having issues with their existing process of an operator applying glue to a plastic foot rest and setting on an automotive carpet. Glue application and foot rest location were inconsistent due to human error. DTI-1330 utilizes a 6-axis collaborative robot to apply glue to the foot rest and apply the part to the carpet accurately and consistently.

Description

Once the operator has placed a carpet and foot rest on the machine, the assembly machine will verify that the parts are present, orientated correctly, and even verify matching colors. The 6-axis collaborative robot will then pick the foot rest up with vacuum cups, apply a hot melt glue to the back, and place the part on the carpet. The finished product is removed and another foot rest and carpet put in its place.

Specifications

| Product Being Processed | Automotive carpet, plastic part |

| Overall Length, Width, Height | 5′-5″ L x 6′-0″ W x 6′-2″ H (1651mm x 1829mm x 1880mm) |

| Heated Chamber Length, Width, Height | N/A |

| Type of Heating System | N/A |

| Design Operating Temperature | N/A |

| Maximum Operating Temperature | N/A |

| Product Support | Base frame with assembly buck/fixture and collaborative robot with end of arm tooling |

| Controls | PLC controls with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. can design and manufacture more than just ovens to meet many unique process requirements, including but not limited to, the following:

- Industries Served: Automotive, aerospace, textile

- Materials Processed: Automotive acoustics, carpet, plastics

- Other Processes: Assembly, inspection