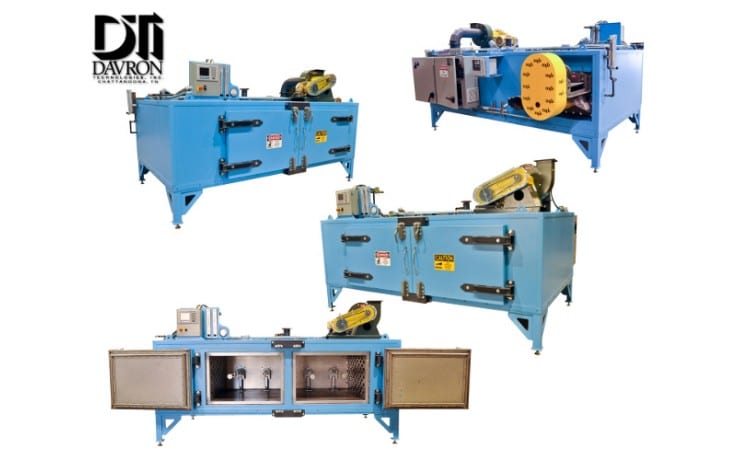

DTI-1118 Inert Atmosphere Batch Oven

DESCRIPTION

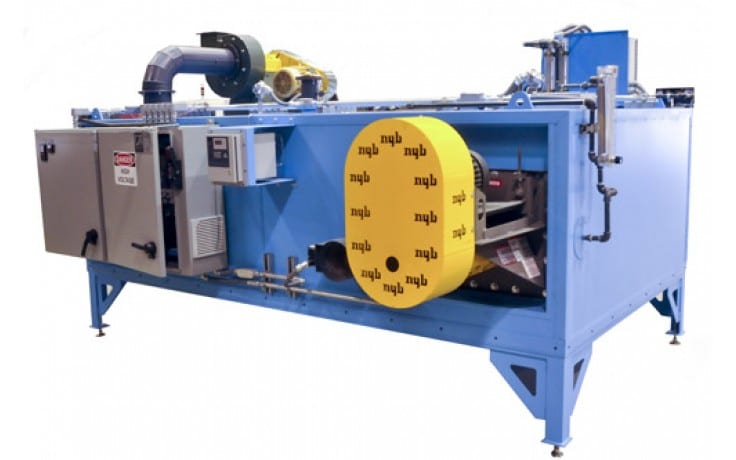

The DTI-1118 inert atmosphere batch oven is used in the manufacturing of membranes that are used in blood purification processes.The oven can accommodate up to four (4) rolls of membrane in the oven per batch. A series of dampers allows the nitrogen atmosphere to circulate throughout the oven chamber, through the center of the membrane roll, or both. The purge cycle is automatic, and nitrogen is supplied to the chamber until the oxygen level has reached less than 1%.Once the oxygen level is below 1% the heat cycle begins.

The PLC control system allows the oven to accommodate multiple heating profiles for different products. The oven can run both non-nitrogen profiles and nitrogen atmosphere profiles.

SPECIFICATIONS

| Overall dimensions | 6′-2″ L x 9′-2″ W x 4′-5″ H (1880mm x 2794mm x 1346mm) |

| Interior dimensions | 4′-6″ L x 6′-2″ W x 2′-0″ H (1372mm x 1880mm x 610mm) |

| Insulation thickness | 4″ (102mm) |

| Heat source | Single electric heater controlled by SCR |

| Maximum operating temperature | 400°F (204°C) |

| Operating temperature | 150°F – 400°F (66°C – 204°C) |

| Airflow | Horizontal cross flow |

| Operating voltage | 480V / 3-phase / 60-hertz |

| Control | PLC with operator touch screen controls all functions of the oven |

| Fans | One (1) circulation fan, Oven utilizes one (1) cooling jacket |

| Pressure gauge for monitoring chamber pressure | |

| Misc | Oven utilizes flow meter to control the flow rate of inert gas entering the chamber |

ALTERNATIVE CAPABILITIES

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous