Building materials

Custom thermal processing equipment for building materials manufacturers

You can’t sell bad boards.

But when you’re manufacturing and finishing fiber or composite siding and other building materials, they’re all too common if you don’t have uniformity in your heated air velocity and temperature.

How do you get that type of controlled heat application?

You need an oven manufacturer that gets building materials, like Davron.

Get A Quote (New w/ file upload)

"*" indicates required fields

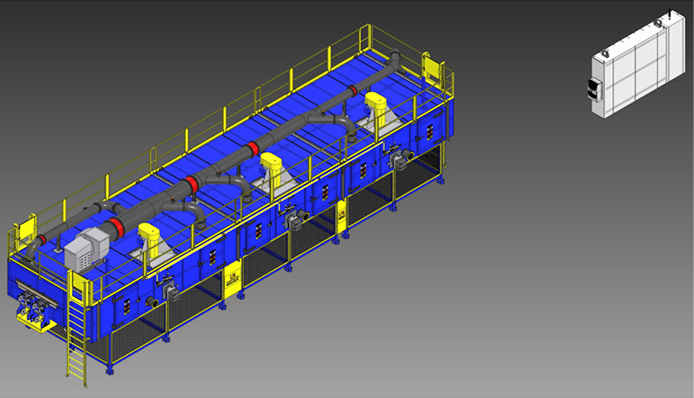

Ovens designed for building materials manufacturers

Precise heat application results in higher-quality finishes

Blistering, uneven finishes, premature paint failure — you run these risks when your oven can’t achieve uniform heated air velocity and temperature through the entire chamber’s width and length.

But with Davron’s decades of engineering experience, you can eliminate bad finishes by applying controlled heat to preheat and cure your paint with forced air impingement. And best-in-class structural design and accurate temperature profiles hold that heat steady over time.

Integrate upstream and downstream equipment with ease

From preheat and curing ovens, to cooling chambers and custom-engineered painting equipment, Davron can handle all the major processing equipment for your line, including some auxiliary equipment.

100% custom. One trusted partner. Your crucial building materials processing equipment, including multi-layer paint applications.

Case study: Faster throughput with half the footprint

A composite board manufacturer came to us for a new version of the thermal processing equipment they currently had — a gas IR heat oven. Inefficient, twice as big as it needed to be and a lot of technical work to maintain.

We explored that idea. But our engineers also explored another concept. One with a gas burner and a single fan to recirculate the air. Greater throughput, higher operational efficiency and a lower initial investment. After proof of concept and ROI, they agreed.

Our team has built hundreds of unique ovens. We understand what works, what works better and what works best for you.

A design process that can meet the most challenging spec

Your process parameters aren’t captured by standard equipment from an online catalog. We don’t do catalogs — we do what you need.

-

- Big enough to drive through — or small enough to fit a tight footprint

-

- Precise control of temperature, throughput and even the atmosphere

-

- Smart airflow design that can deliver any heating or cooling profile

-

- Installation weeks faster than our competitors through smart design

-

- Thermal processing that integrates smoothly with the rest of your line

-

- Durable equipment, built at our 70,000-square-foot facility in Chattanooga

Take control of your finish quality

Manufacturing fiber or composite siding? Another type of building material? Then your customers are depending on even and accurate heat.

Let’s make it happen. Contact Davron to discuss the needs of your building material production line.